Capacitance energy accumulation type fusing soldering welder

A capacitor energy storage type, fusion welding technology, applied in systems, electrical components, nail tools, etc. for storing electrical energy, can solve the problems of easily damaged body, vulnerable transformers, endangering personal safety, etc., and achieve the effect of solving easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

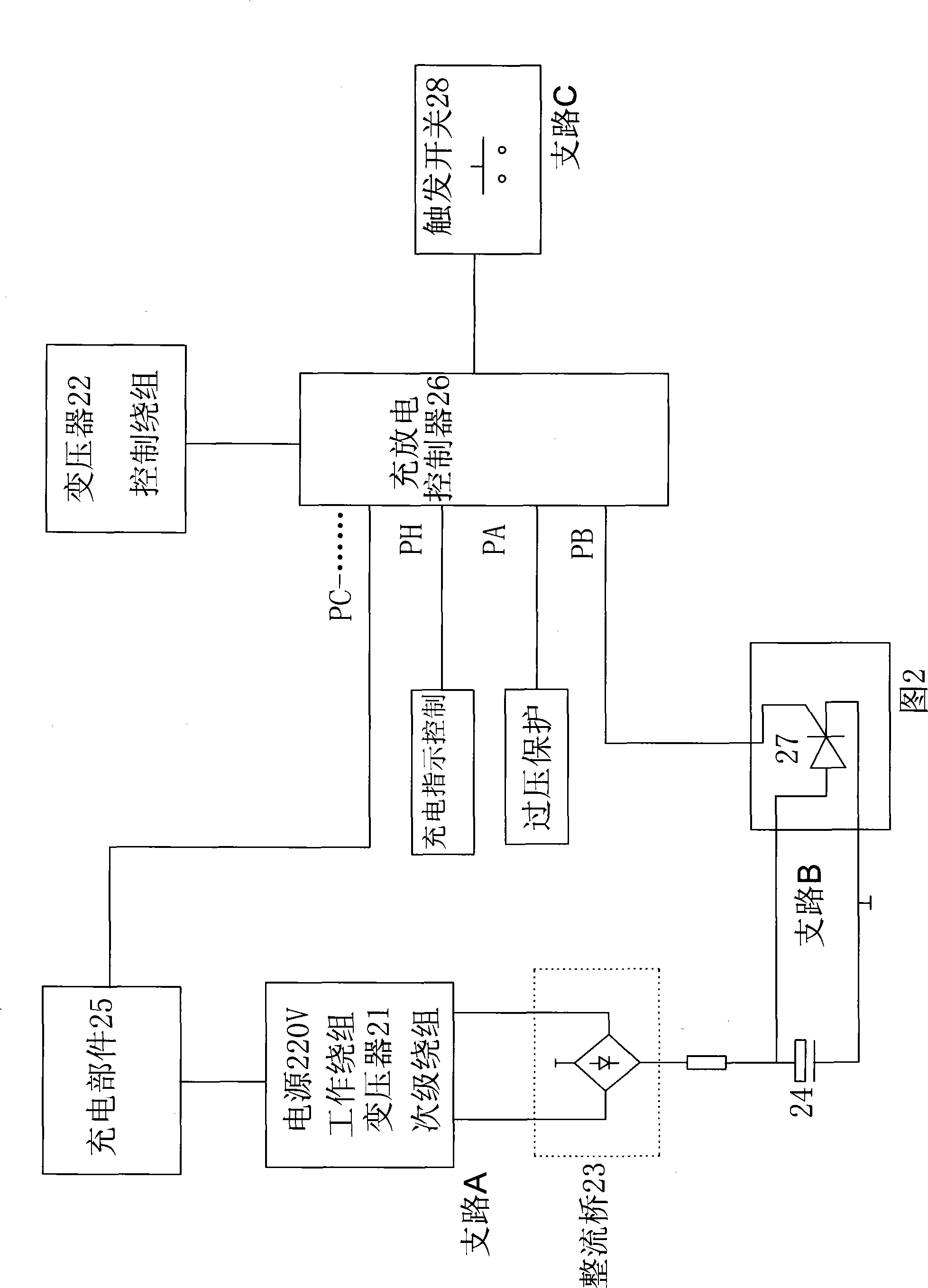

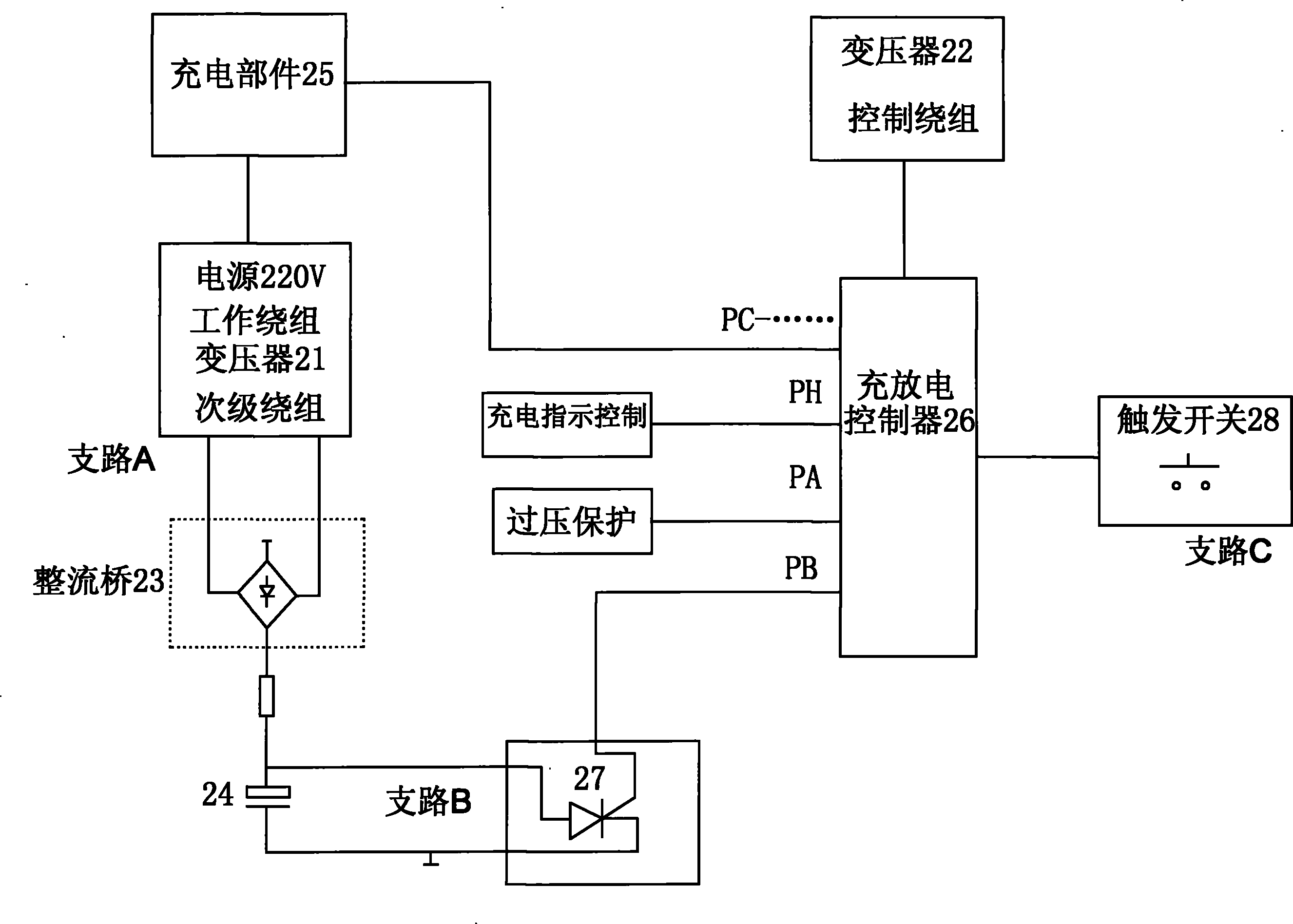

[0016] figure 2 Among them, the charging and discharging controller 26 has multiple output terminals, among which the main terminals such as PA, PB, PC, etc. are connected with each branch and controlled by it in sequence.

[0017] In order to achieve the purpose of being controlled by timing pulses and working reliably: the circuit is specifically designed as follows:

[0018] Among them, the charging component 25, the transformer 21, the rectifier bridge 23, and the energy storage capacitor 24 form the charging branch A; the discharge thyristor 27 and the energy storage capacitor 24 form the discharging branch B, and the trigger switch 28 cooperates with the charge and discharge controller 26 to form a control circuit. Branch C.

[0019] 1. Transformer selection: the working winding and the control winding group of the present invention are divided into two transformers 21 and 22. Because the circuit efficiency is high, the respective powers are all small, and the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com