Interior automotive trim part and process for producing the same

A manufacturing method and interior technology, applied to vehicle parts, household components, chemical instruments and methods, etc., can solve the problems of reduced rigidity, resin drooping (falling, low melt flow rate, etc.), and achieve the effect of light weight and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

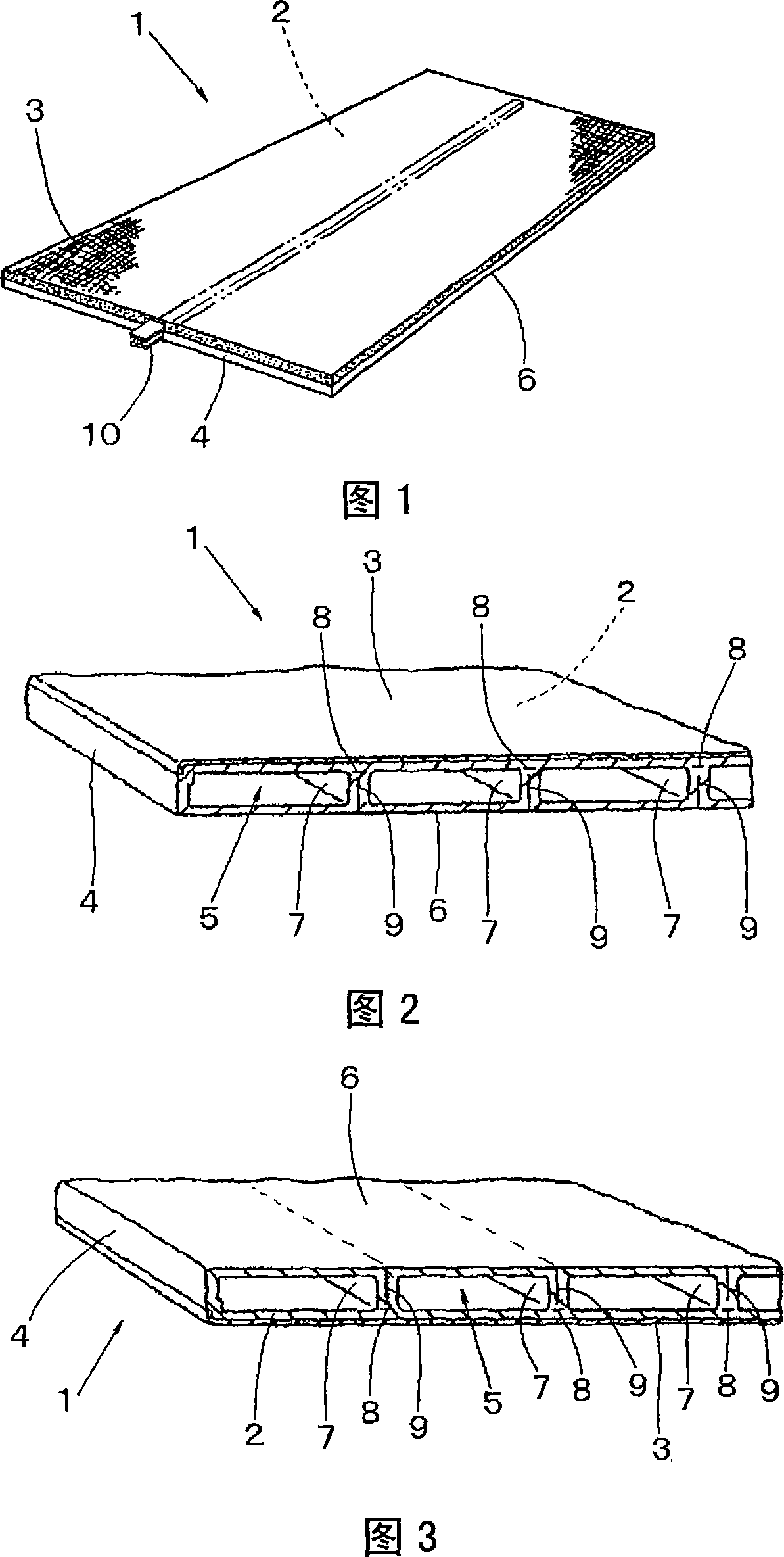

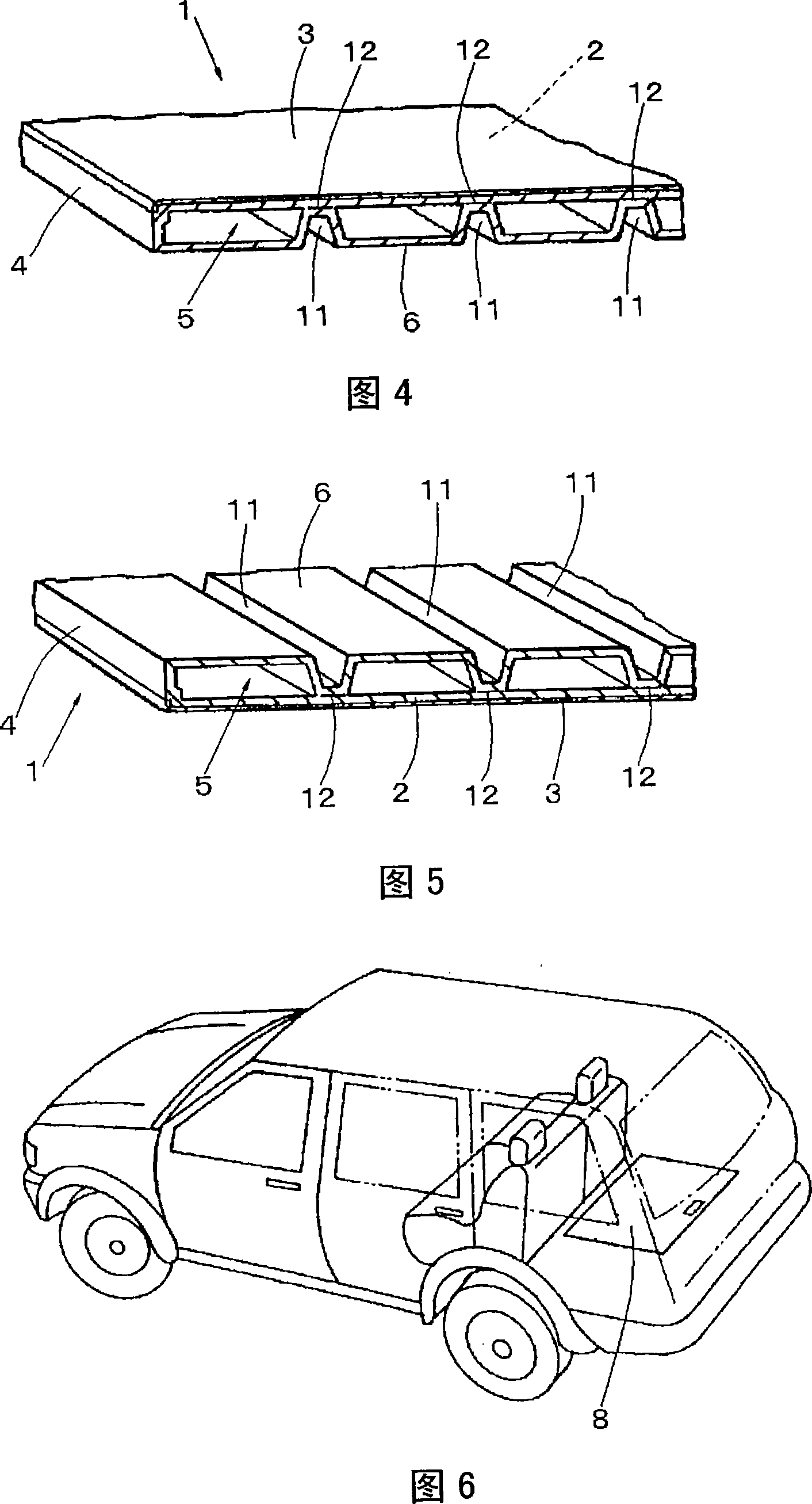

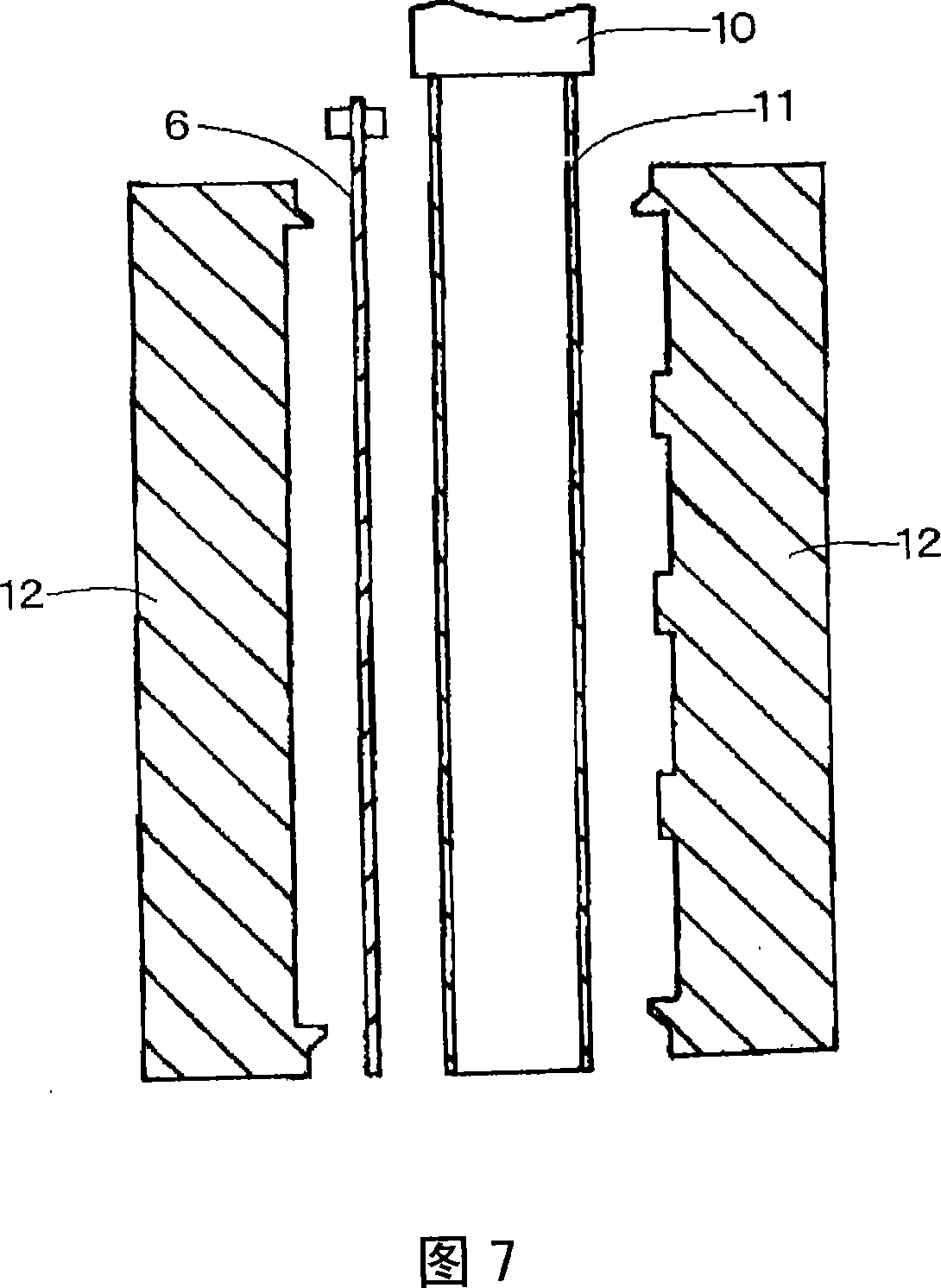

[0040] Next, in order to describe the present invention in more detail, it will be described with reference to the drawings. Fig. 1 is a perspective view showing a panel with a hollow double-wall structure as an example of an automotive interior part of the present invention, and Fig. 2 is a perspective view showing a part of the panel as seen from the surface of the panel shown in Fig. 1 , and Fig. 3 1 is a partially broken perspective view seen from the inside of the plate shown in FIG. 1 , and FIG. 4 is a partially broken perspective view seen from the surface of the plate of another embodiment. FIG. It is a partially cutaway perspective view seen from the inside of the board of another embodiment. In addition, automotive interior parts are cargo floor panels (automobile cargo compartment covers or cargo racks), rear parcel racks, and the like formed by blow molding.

[0041] In FIGS. 1 to 3 , 1 is a board manufactured by blow molding thermoplastics. The plate 1 is made i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com