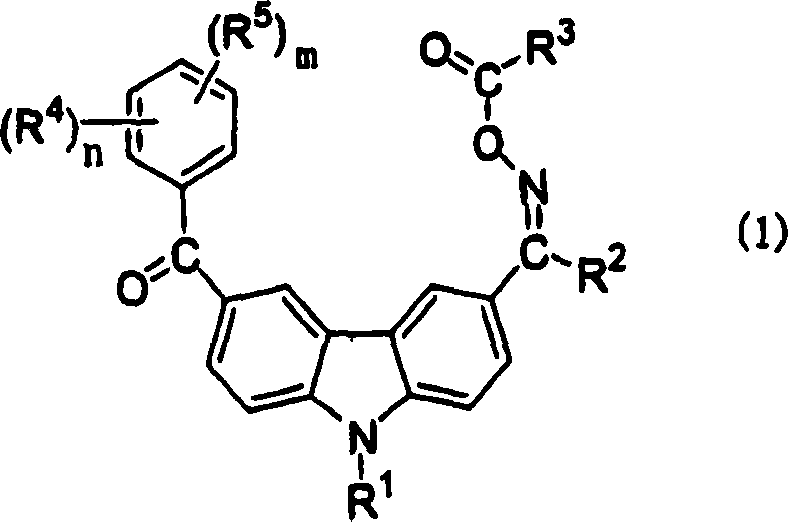

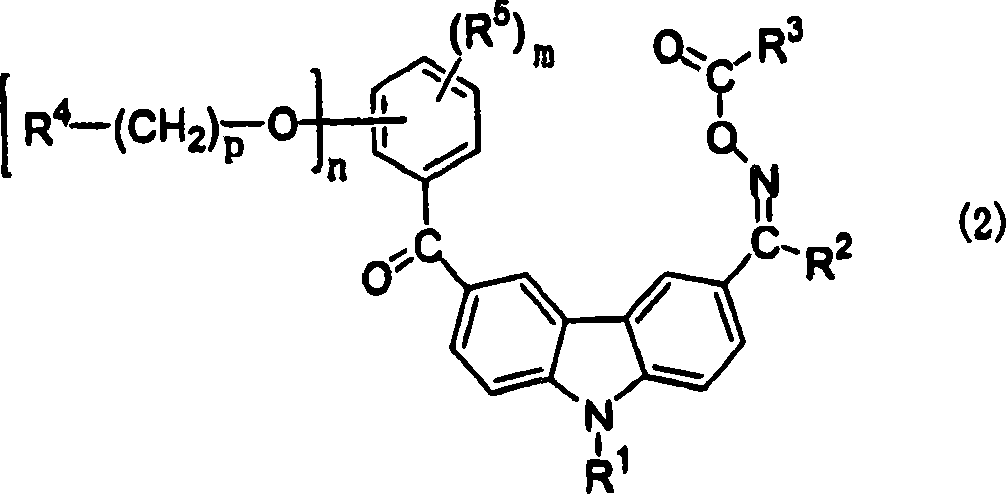

Radiation sensitive resin composition for forming a colored layer and color filter

A resin composition and sensitive technology, applied in the field of color liquid crystal display elements, can solve problems such as prolonged vacuum baking time and reduced productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0281] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited to the following examples.

[0282] (A) 15 parts by weight of a mixture of C.I. Pigment Red 254 / C.I. Pigment Red 177=80 / 20 (weight ratio) as a colorant, 4 parts by weight of Disperbyk-2001 (in terms of solid content) as a dispersant, and (B) Methacrylic acid / N-phenylmaleimide / styrene / benzyl methacrylate copolymer (copolymerization weight ratio=20 / 30 / 20 / 30, Mw=9500, Mn=5000) 6 parts by weight and 75 parts by weight of propylene glycol monomethyl ether acetate as a solvent (E) were treated with a bead mill to prepare a pigment dispersion (R1).

[0283] Next, 100 parts by weight of the pigment dispersion liquid (R1), methacrylic acid / succinic acid mono[2-methacryloyloxyethyl] ester / N-phenylmaleic acid as (B) alkali-soluble resin Imide / styrene / benzyl (meth)acrylate copolymer (copolymerization weight ratio=25 / 10 / 30 / 20 / 15, Mw=12000, Mn=6500...

Embodiment 2

[0308] Except that the (E) solvent added to 100 parts by weight of the pigment dispersion (R1) in Example 1 was changed to 50 parts by weight (20 weight %) of cyclohexyl acetate and 125 parts by weight of ethyl 3-ethoxypropionate Except (50 weight part), it carried out similarly to Example 1, the composition (R1-2) for coloring layer formation was prepared, and it evaluated again. Moreover, the (E) solvent in the composition (R1-2) for coloring layer formation contained 75 weight part (30 weight%) of propylene glycol monomethyl ether acetate further. The evaluation results are shown in Table 1.

Embodiment 3

[0310] In addition to changing the (E) solvent added to 100 parts by weight of the pigment dispersion (R1) in Example 1 to 50 parts by weight (20% by weight) of cyclohexyl acetate, 50 parts by weight (50 parts by weight) of propylene glycol monomethyl ether acetate % by weight), 25 parts by weight of diethylene glycol methyl ethyl ether (10% by weight) and 50 parts by weight of 3-methoxybutyl acetate (20% by weight), operate in the same manner as in Example 1 to prepare the colored layer Formation composition (R1-3) was evaluated. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com