Combined type press hydraulic cylinder

A technology for hydraulic cylinders and presses, which is applied to presses, fluid pressure actuators, cylinders, etc., and can solve problems such as large energy consumption, increased power of hydraulic pumps, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

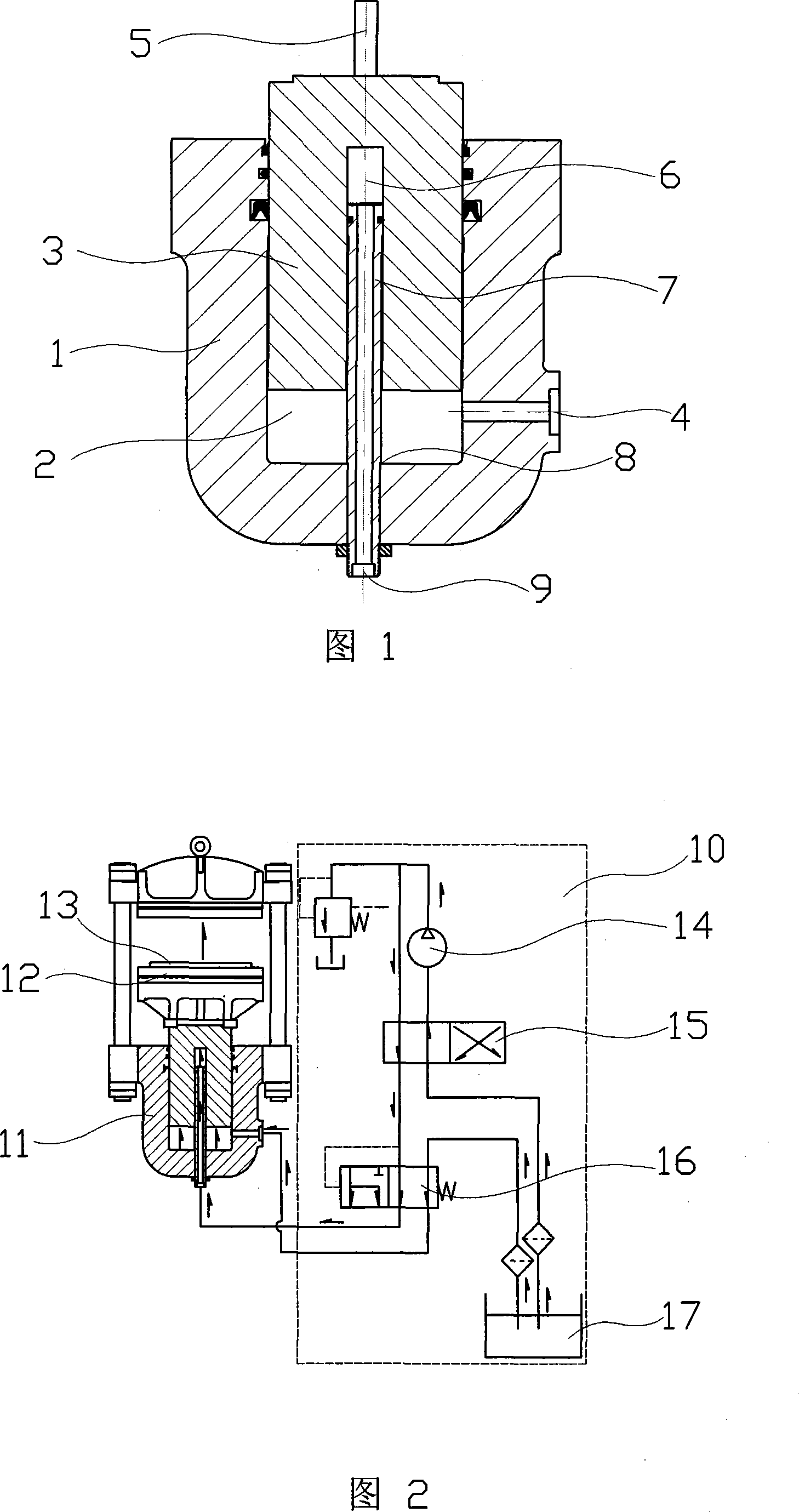

[0015] In Figure 1, the hydraulic cylinder of the combined press has a cylindrical cylinder body 1 with a closed bottom, and a cylindrical hydraulic cylinder cavity 2 in the cylinder body, and a cylindrical hydraulic cylinder cavity matching the hydraulic cylinder cavity. Piston 3, there is a liquid inlet and outlet 4 on the side wall of the bottom end of the cylinder body, the outer end of the piston can be connected with a piston rod 5, there is a piston hydraulic cylinder on the piston, the cylinder body of the piston hydraulic cylinder is a piston, and there is an opening on the axis of the piston facing the hydraulic cylinder Cylindrical piston hydraulic cylinder cavity 6 with the bottom end of the cavity closed, there is a circular tube-shaped piston 7 matching with the internal cavity of the piston hydraulic cylinder, and the circular tube-shaped piston is positioned at the bottom of the cylinder body In the middle 8, the nozzle 9 of the circular tubular piston extends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com