Wind-driven generator protective hood

A technology for wind turbines and protective covers, which is applied in the field of protective covers, and can solve problems such as potential safety hazards in the operation of wind turbines, easy damage to open skylights, and too smooth outer surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

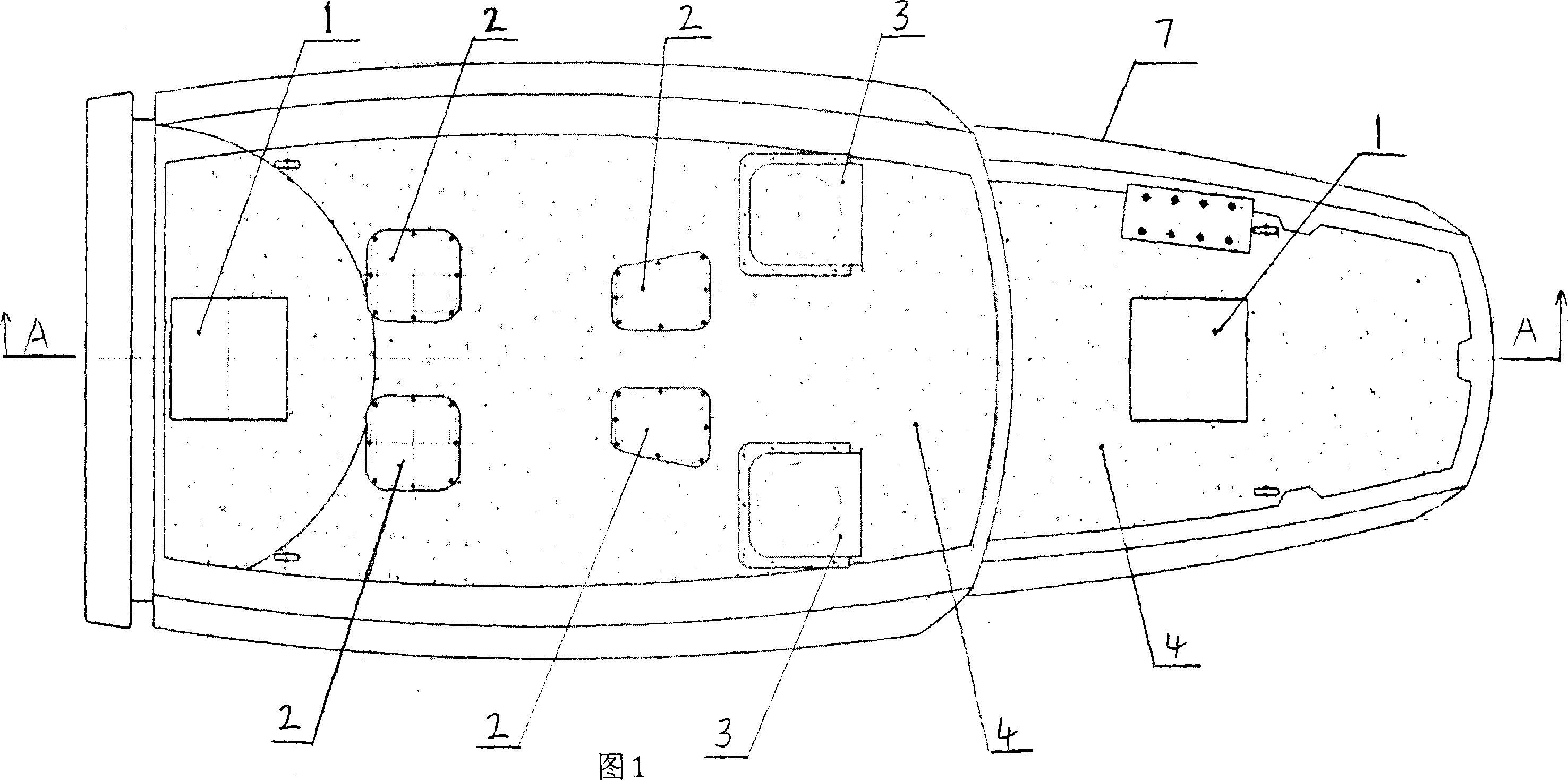

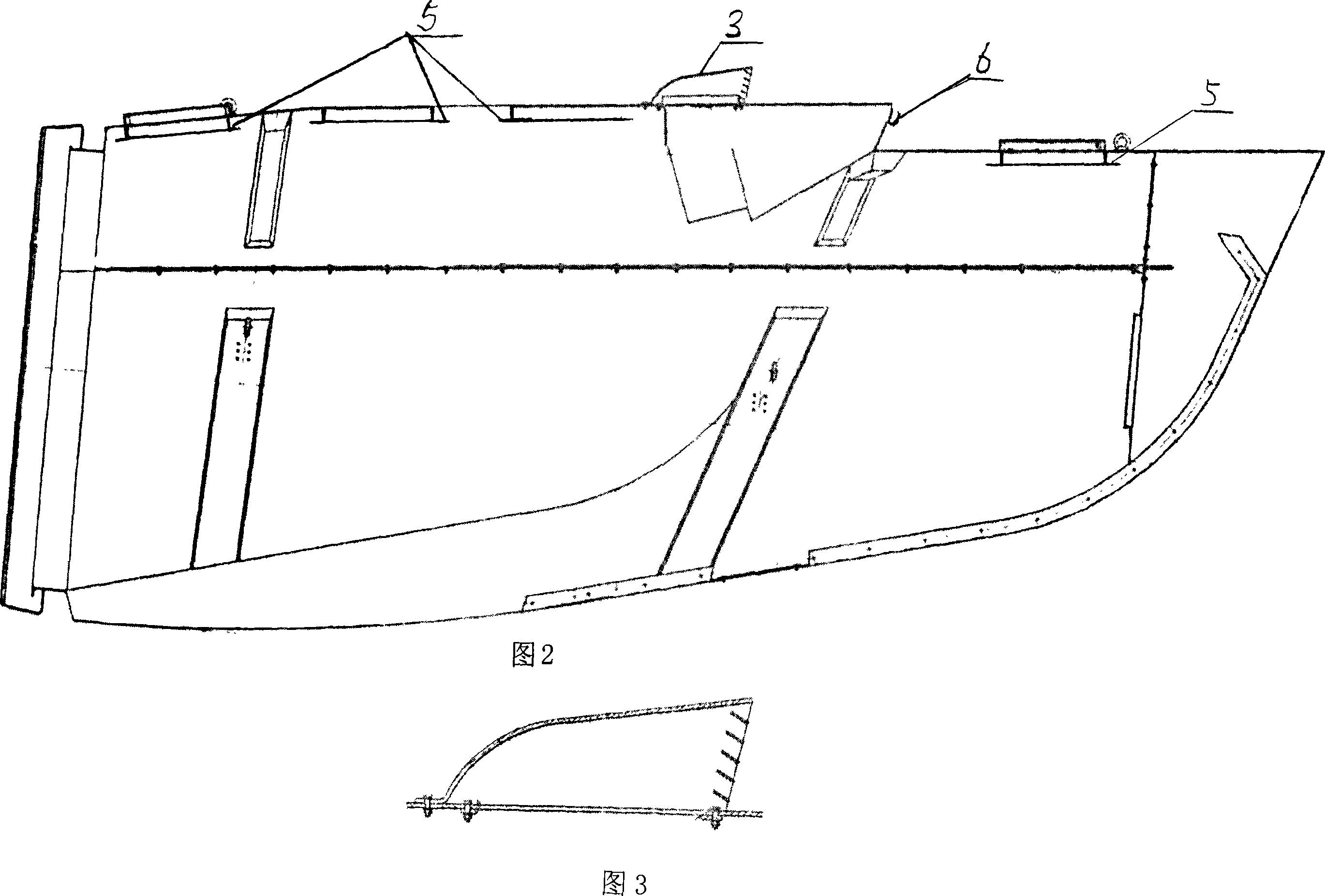

[0018] As can be seen from Fig. 1, Fig. 2 and Fig. 3: the wind turbine protective cover includes a cover body 7, a skylight 1 positioned at the top of the cover body, a hoisting hole 2 and a forced ventilation channel 3, and the cover body 7 is a large left side The cover body is small on the right, high on the left and low on the right. The appearance of the forced ventilation channel 3 is streamlined, and the vents are equipped with shutters;

[0019] It can also be seen from Fig. 1 that a glass fiber reinforced plastic water tank 6 is installed at the air outlet of the ventilation duct.

[0020] It can also be seen from Fig. 1 that before the sponge is pasted, a pressure ring 5 is installed at the hoisting hole and the skylight position.

[0021] The step of sanding treatment is to firstly polish the originally smooth upper surface, then apply resin and sprinkle quartz sand, so that a layer of anti-slip layer with sand particles will be formed on the surface after solidific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com