Plasma film coating device and method

A technology of plasma and coating device, which is used in gaseous chemical plating, metal material coating process, coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

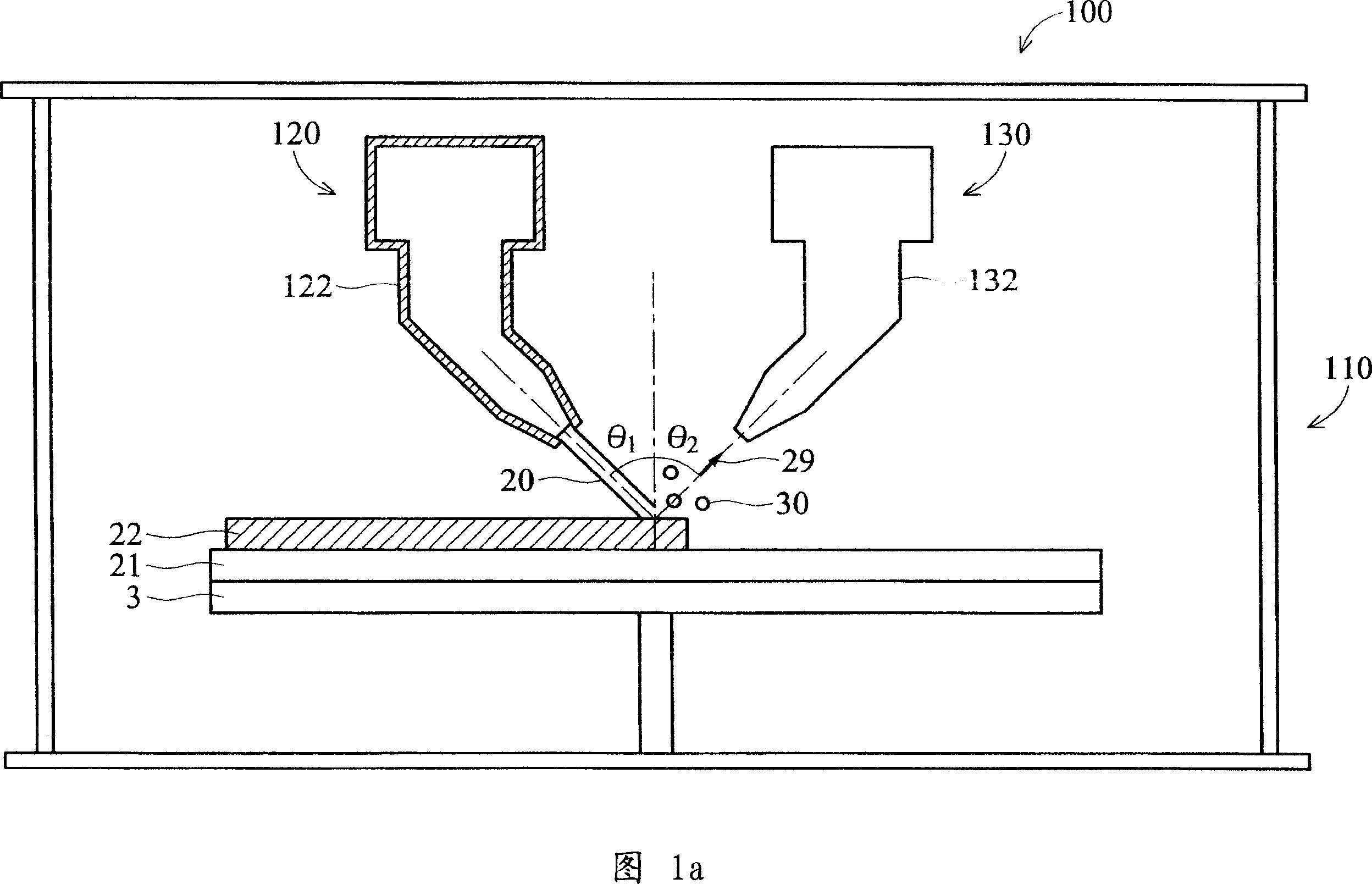

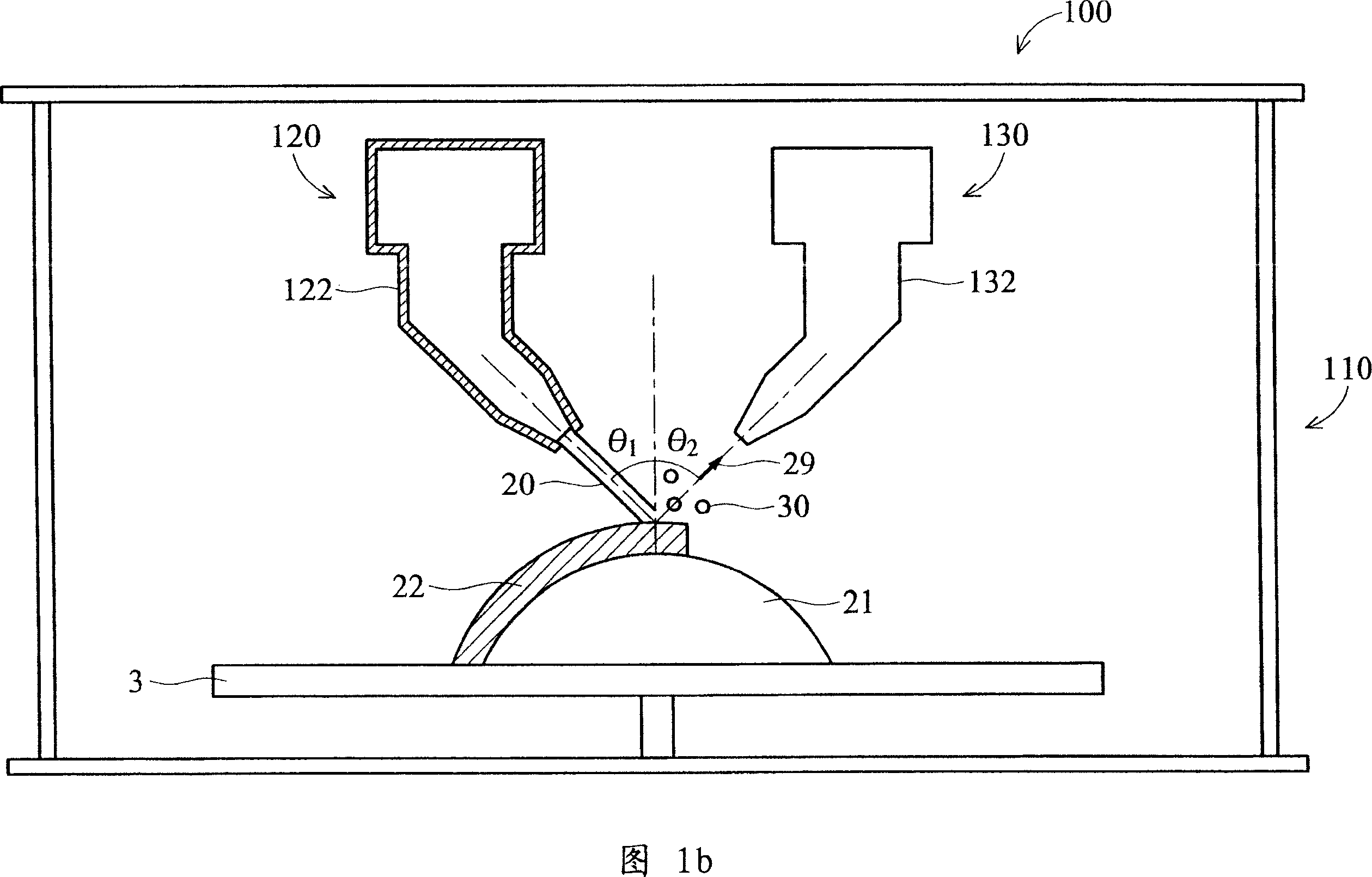

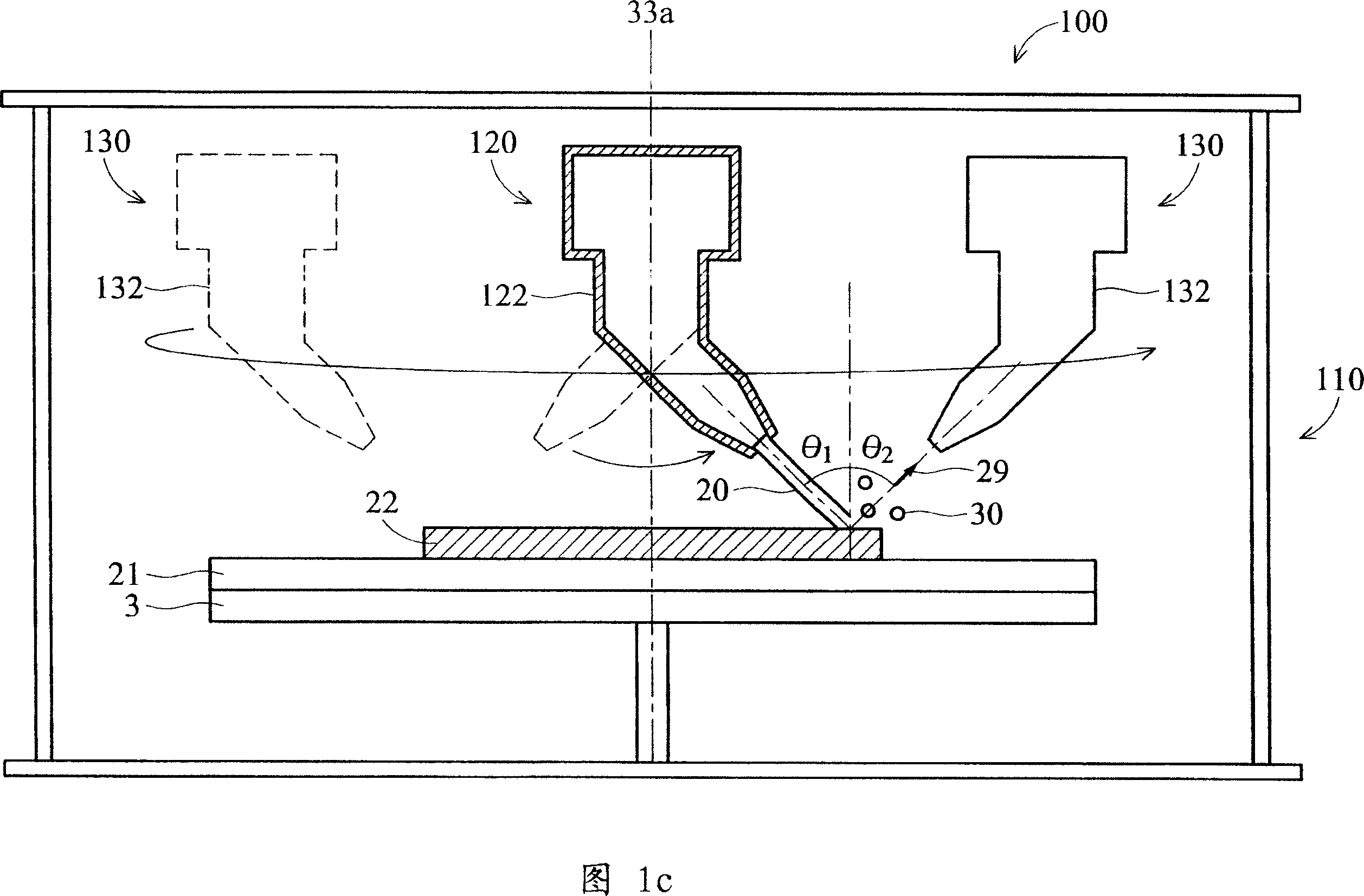

[0034] Hereinafter, the plasma coating device of the preferred embodiment of the present invention will be described in more detail by using the accompanying drawings. Figures 1a to 1g respectively show cross-sectional views of devices of preferred embodiments, and in each embodiment of the present invention, the same symbols represent the same components.

[0035] Please refer to FIG. 1 a , which shows a schematic diagram of a plasma coating device 100 in a first embodiment. The plasma coating device 100 mainly includes a reaction chamber 110 , a carrier 3 , a plasma source generating device 120 and an exhaust device 130 . The reaction chamber 110 is used to provide an environment for plasma coating. The gas pressure of the reaction chamber 110 can be normal pressure (same as external pressure, eg 760 torr) or low pressure (eg 0.1-1 torr). Furthermore, a carrier 3 is provided in the reaction chamber 110 , and the carrier 3 is used to carry the material to be coated. The mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com