Deformation-resisting laminated stickiness bamboo wood board

A kind of anti-deformation, bamboo and wood technology, applied in the direction of wood processing utensils, wood veneer joining, layered products, etc., can solve the problems of hindered promotion, lateral deformation, etc., to improve strength, prevent lateral deformation, and strengthen the combination. The effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

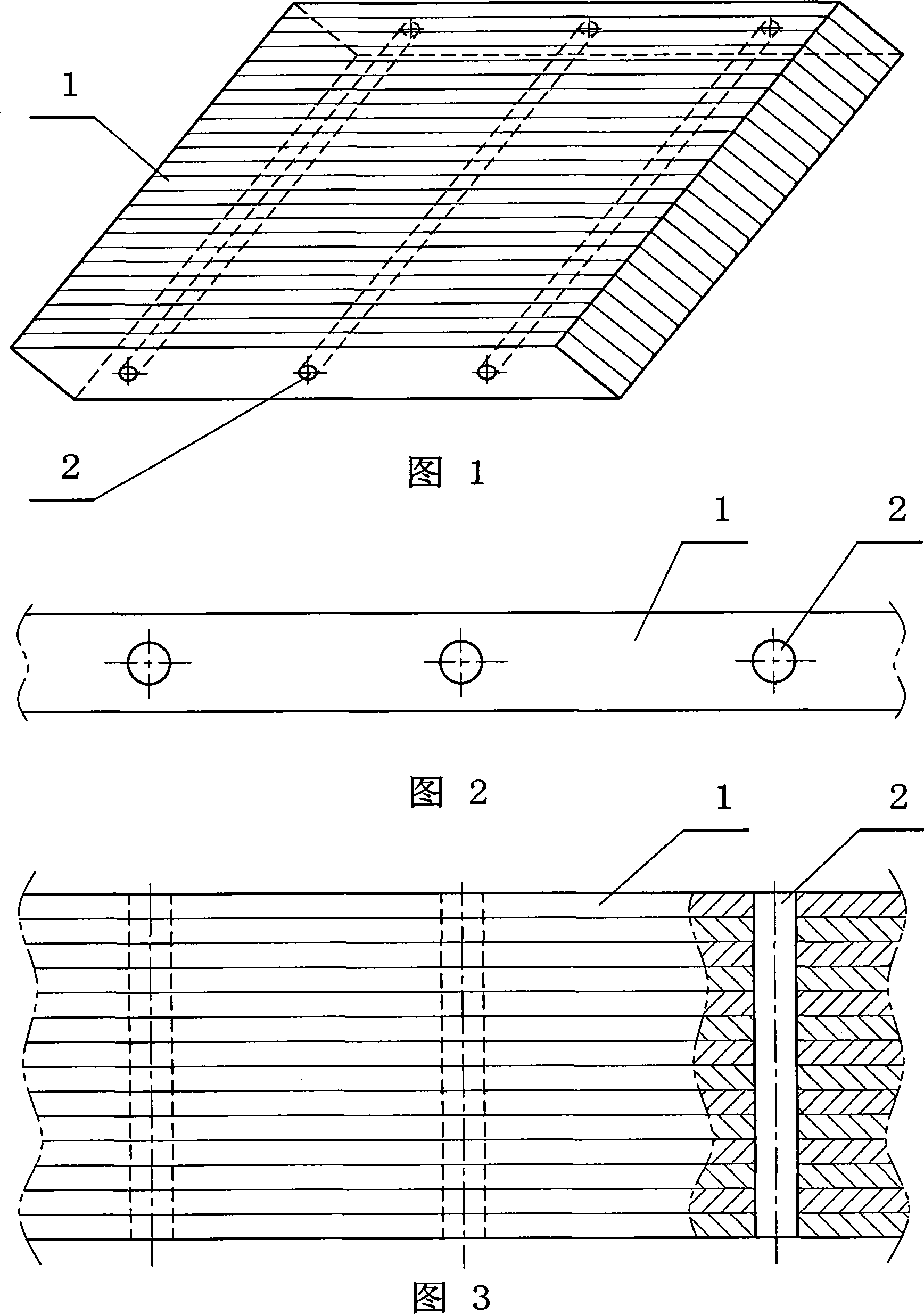

[0013] Embodiment 1 is shown in Figures 1-3: a deformation-resistant bamboo floor, which is made of bamboo sheets perpendicular to the plane of the bamboo floor, glued and laminated. In the bamboo floor 1, the starting point is at the centerline of the side of the bamboo floor 1, along the width direction of the bamboo floor 1 there is a through hole through the full width of the bamboo floor 1, and the circular bamboo bolt rod 2 positioned in the through hole is closely connected to the through hole. Cooperate, the length of circular bamboo bolt rod 2 equals the width of bamboo floor 1.

Embodiment 2

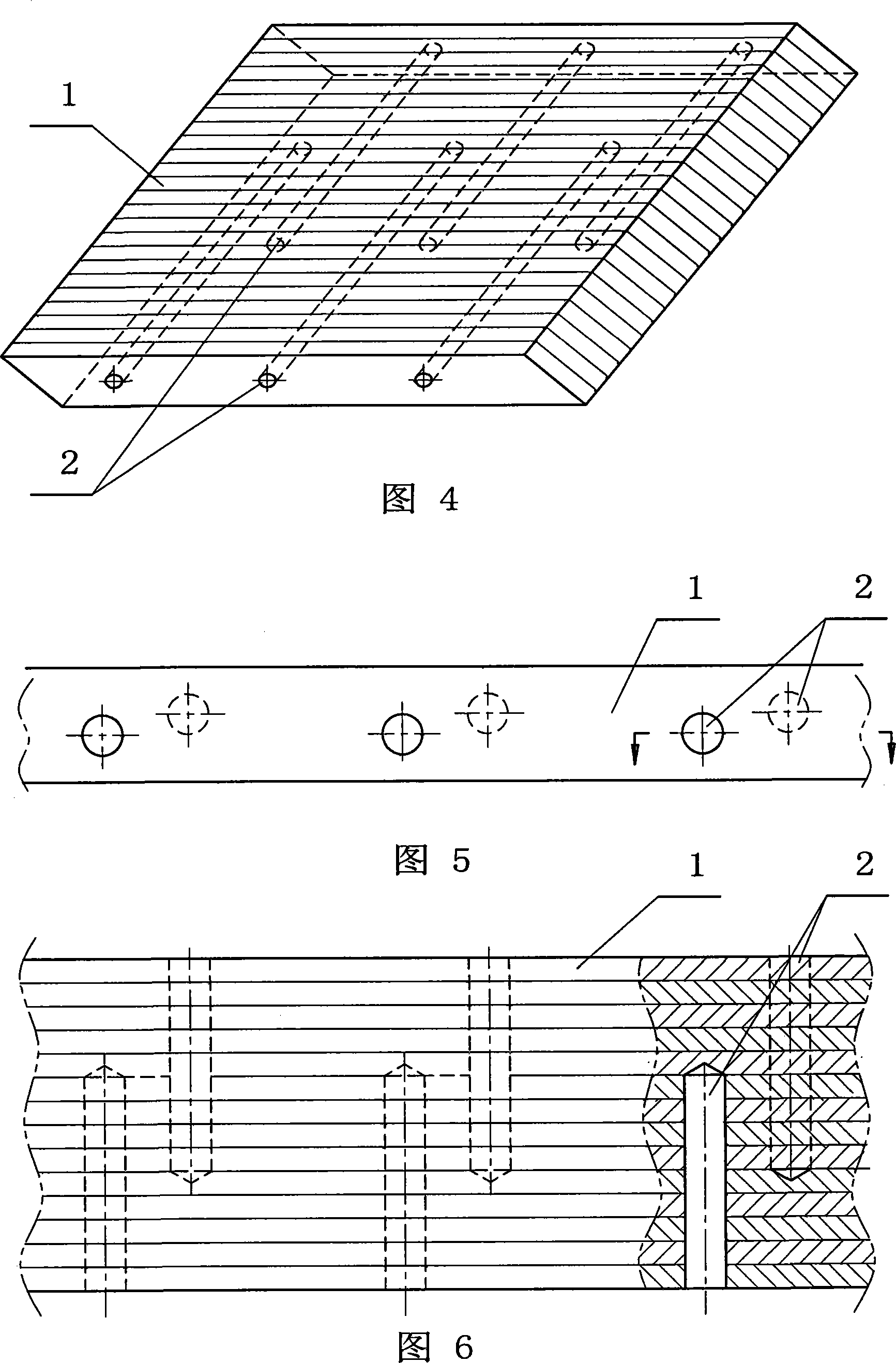

[0014] Embodiment 2 is shown in Figures 4-6: an anti-deformation wooden floor, which is made of wood chips perpendicular to the plane of the wooden floor, glued and laminated. In the said wooden board 1, the starting point is at the two sides of the wooden board 1, and along the width direction of the wooden board 1, there are blind holes staggered towards each other, and the antirust steel square bolt rod 2 located in the blind hole is tightly connected to the blind hole. Cooperate; the length of the antirust steel square bolt bar 2 is equal to 2 / 3 of the width of the bamboo board 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com