Technique of catalytic oxidation flue gas desulfurization and hydrocarbonylation by-product polymerization iron sulfate

A technology of polymerizing ferric sulfate and catalytic oxidation, which is applied in the field of flue gas purification, can solve the problems of low added value, high cost of desulfurization, incomplete oxidation of ferrous ions, etc., and achieve the effect of reducing raw material costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

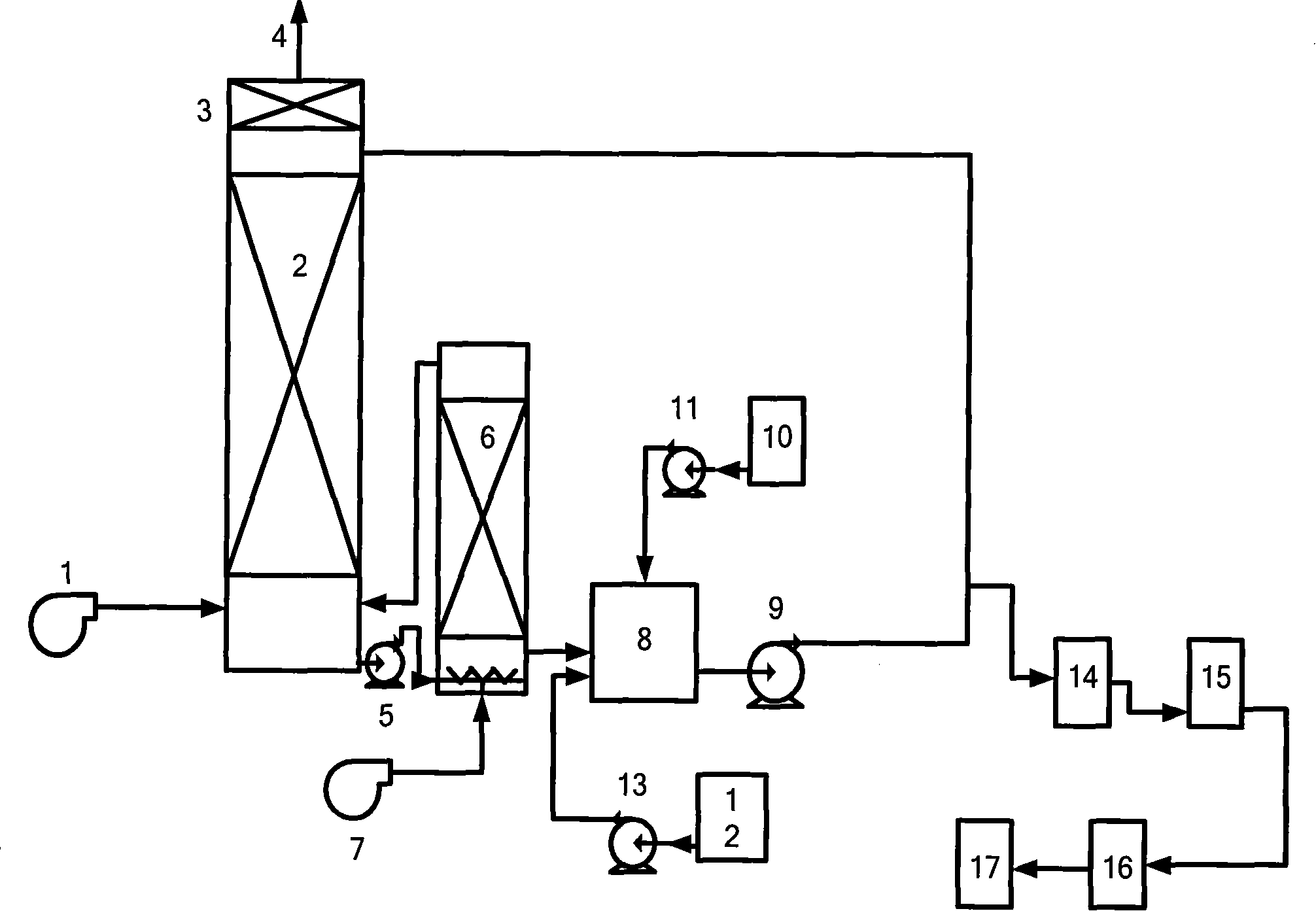

Method used

Image

Examples

Embodiment 1

[0037] A 75t / h coal-fired thermoelectric boiler with a flue gas flow rate of 100,000 Nm 3 / h,SO 2 The content is 1500mg / Nm 3 , the flue gas temperature is 130°C, according to the process of the present invention, when leaving the desulfurization tower, the SO in the desulfurization tail gas 2 Content 150mg / Nm 3 , the flue gas temperature is 50°C, and the desulfurization efficiency is 90%.

[0038] The desulfurization tower is a packed tower with a diameter of 6m and a height of 28m. The packing is a stepped ring made of reinforced polypropylene with a nominal diameter of 50mm

[0039] The gas residence time of the desulfurization tower is 11s

[0040] The oxidation tower is a bubble tower, and the liquid residence time is 20min

[0041] The liquid-gas ratio of the desulfurization tower is 6L / Nm 3 , absorption liquid flow 600m 3 / h

[0042] The reaction pressure controlled by the desulfurization tower, oxidation tower and circulating reaction pool is normal pressure, an...

Embodiment 2

[0053] A 220t / h coal-fired thermoelectric boiler with a flue gas flow rate of 250,000 Nm 3 / h,SO 2 The content is 1500mg / Nm 3 , the flue gas temperature is 130°C, according to the process of the present invention, when leaving the desulfurization tower, the SO in the desulfurization tail gas 2 Content 150mg / Nm 3 , the flue gas temperature is 50°C, and the desulfurization efficiency is 90%.

[0054] The desulfurization tower is a packed tower with a diameter of 8.5m and a height of 32m. The packing is a stepped ring made of reinforced polypropylene with a nominal diameter of 50mm

[0055] The gas residence time of the desulfurization tower is 11s

[0056] The oxidation tower is a bubble tower, and the liquid residence time is 20min

[0057] The liquid-gas ratio of the desulfurization tower is 6L / Nm 3 , absorption liquid flow rate 1500m 3 / h

[0058] The reaction pressure controlled by the desulfurization tower, oxidation tower and circulating reaction pool is normal pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com