Sparking plug with full-ceramic electrically-heated body as center electrode

A center electrode and spark plug technology, applied in the field of electric spark ignition equipment, can solve the problems of energy absorption, low temperature of the cold electrode, affecting smooth ignition, etc., and achieve the effect of not easy to deposit carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

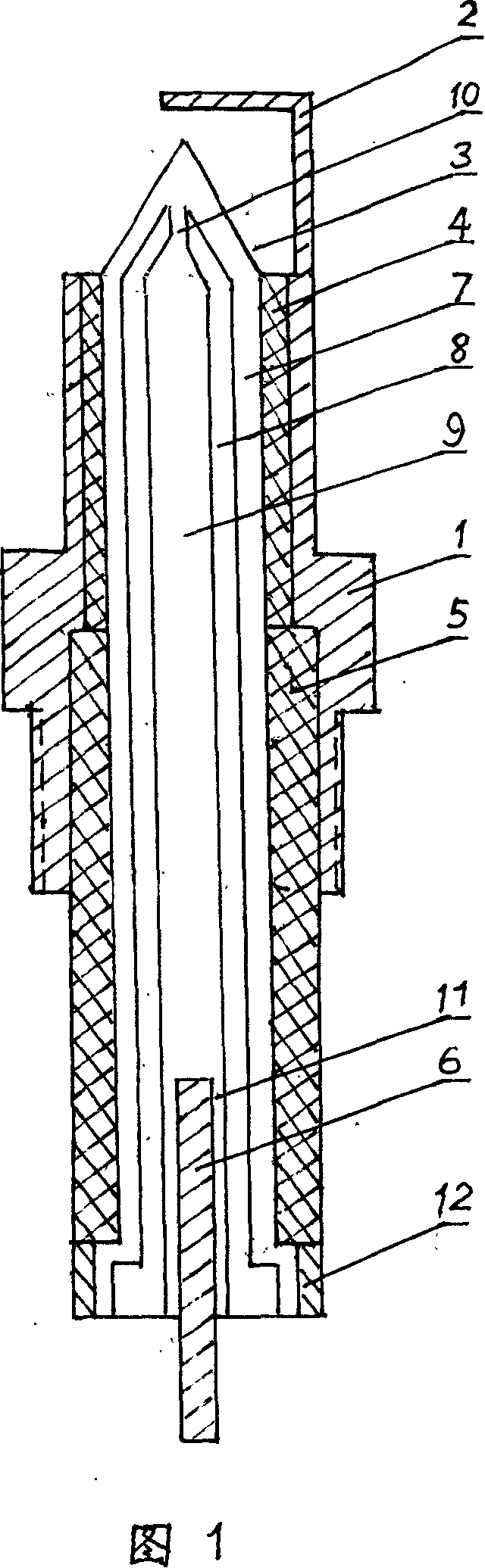

[0008] The specific implementation is as follows: including spark plug housing 1, side pole 2, center electrode 3, upper insulating tube 4, lower insulating tube 5 and conductive electrode 6; spark plug housing 1 made of metal material is installed on the engine and grounded, and the spark plug The inner hole of the shell 1 is divided into two sections, the inner diameter of the lower section of the inner hole is larger than the inner diameter of the upper section of the inner hole; the side electrode 2 is connected with the spark plug shell 1; the center electrode 3 made of an all-ceramic electric heater is installed in the inner hole of the spark plug shell 1 In the upper section, there is a certain gap between its upper end and the side electrode 2. The center electrode 3 includes an outer resistance layer 7, an insulating layer 8 and an inner conductive layer 9. The outer resistance layer 7, the insulating layer 8 and the inner conductive layer 9 are made of conductive ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com