Automatic decoking stopcock

An automatic, cock body technology, applied in the direction of cocks, valve details, valve devices, etc. including the cut-off device, can solve problems such as jamming, sealing surface wear, and inappropriateness, so as to prolong service life, prevent high temperature swelling and improve The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

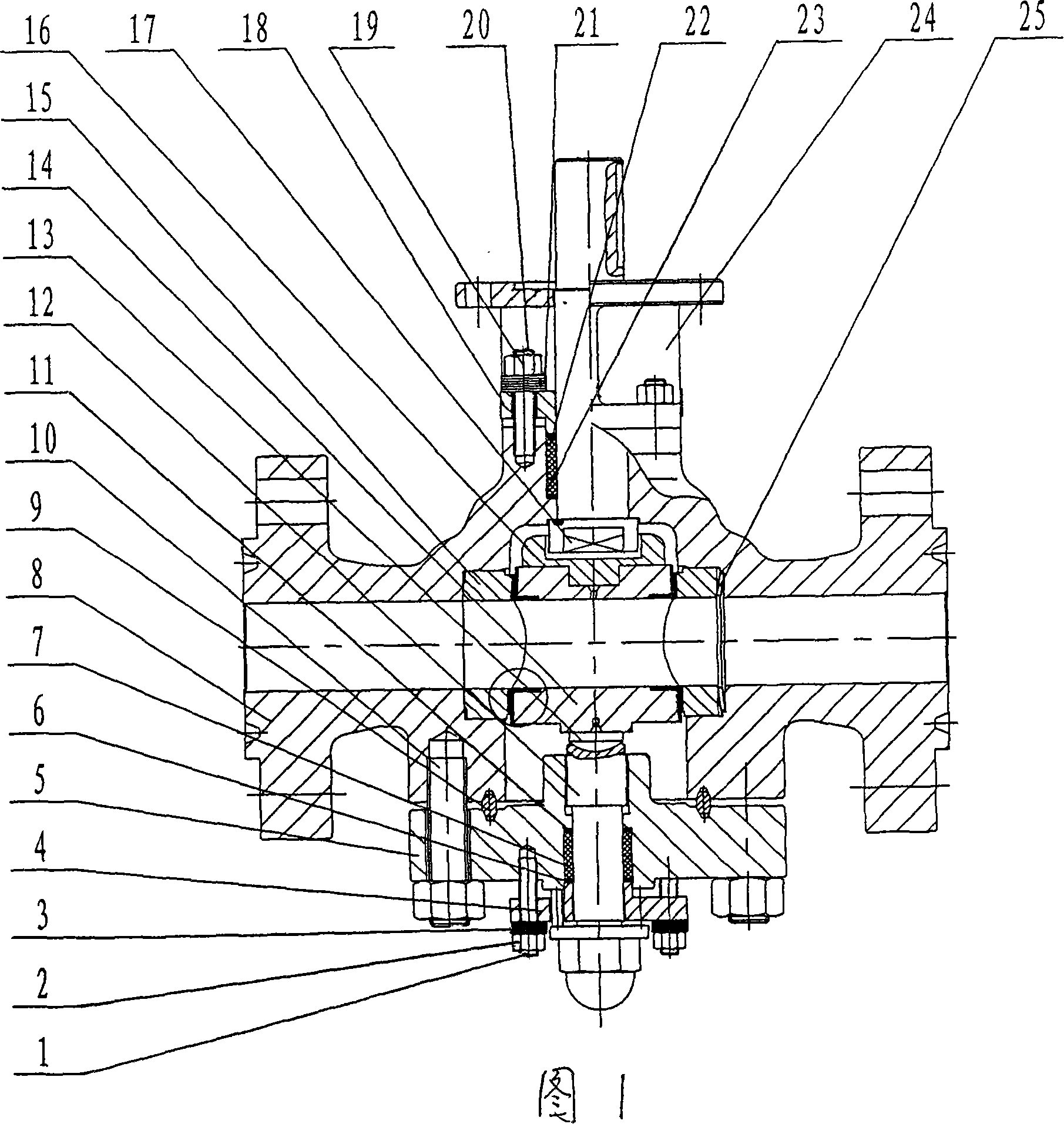

[0010] The automatic decoking plug valve shown in Figure 1 includes a valve body 8, a valve cover 5, a valve stem 17, a cock body 14, a seal and a mounting part, and the valve body 8 is respectively provided with a cock body at the inlet and outlet channels. 14 The tile-shaped valve seat 15 that cooperates with each other. The edges on both sides of the tile-shaped valve seat 15 are made into a scraper-type structure with acute angles. The spring 25 is a belleville spring. The tile-shaped valve seat 15 has an inner arc that cooperates with the outer cylindrical surface of the cock body 14, and the sharp-angled scrapers on both sides of the seat can scrape off the coke stuck on the surface of the cock body during the opening and closing process of the valve.

[0011] The lower end surface of the cock body 14 is formed with a spherical top block 13, the spherical top block 13 cooperates with the spherical ejector rod 12 below, the convex spherical surface of the spherical top bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com