Skin electrical heating part

An electric heating element and skin-integrated technology, which is applied in the field of electric heating elements based on the principle of electric heating, can solve problems such as electrification, roughness, and danger of the shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

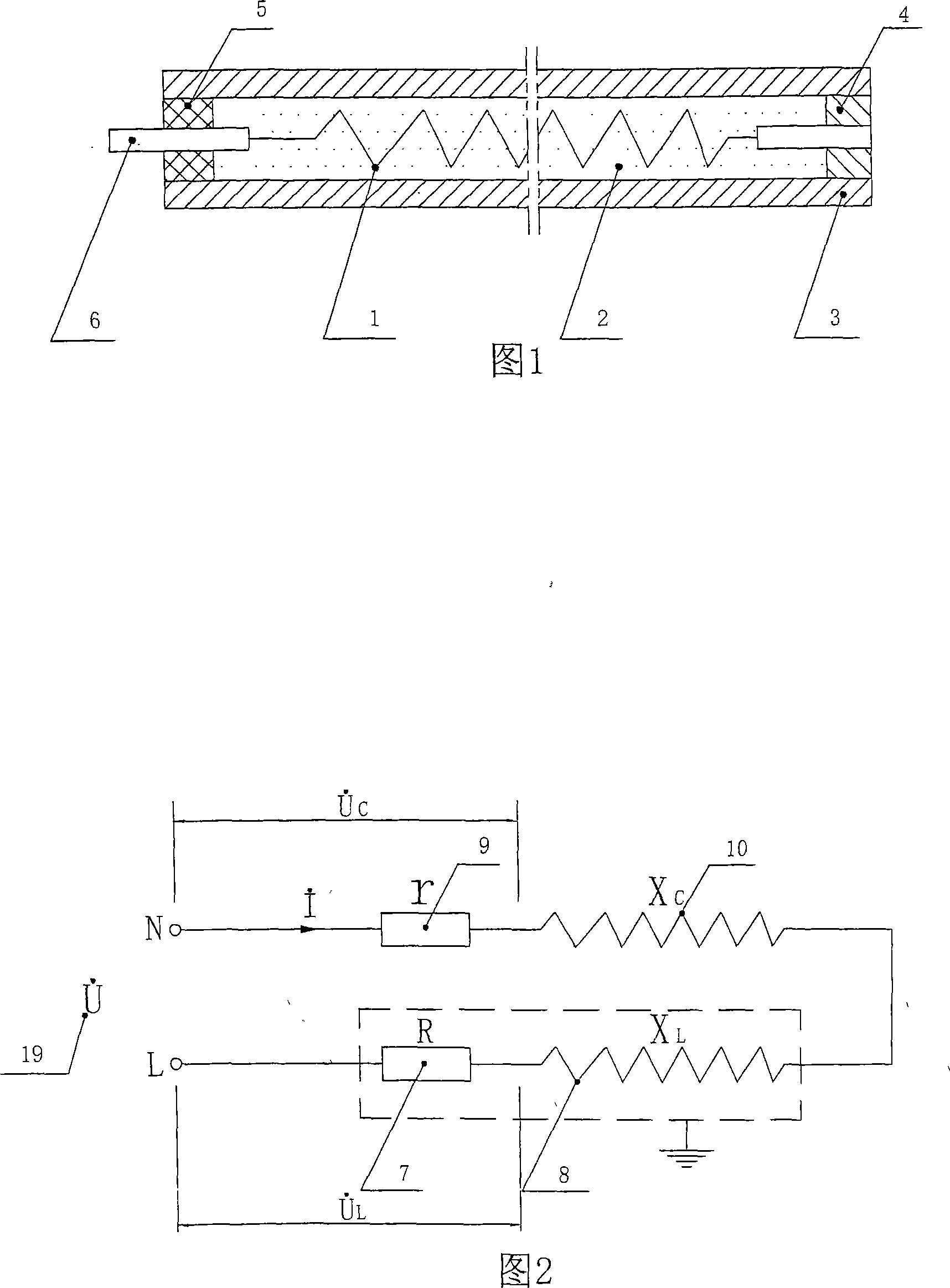

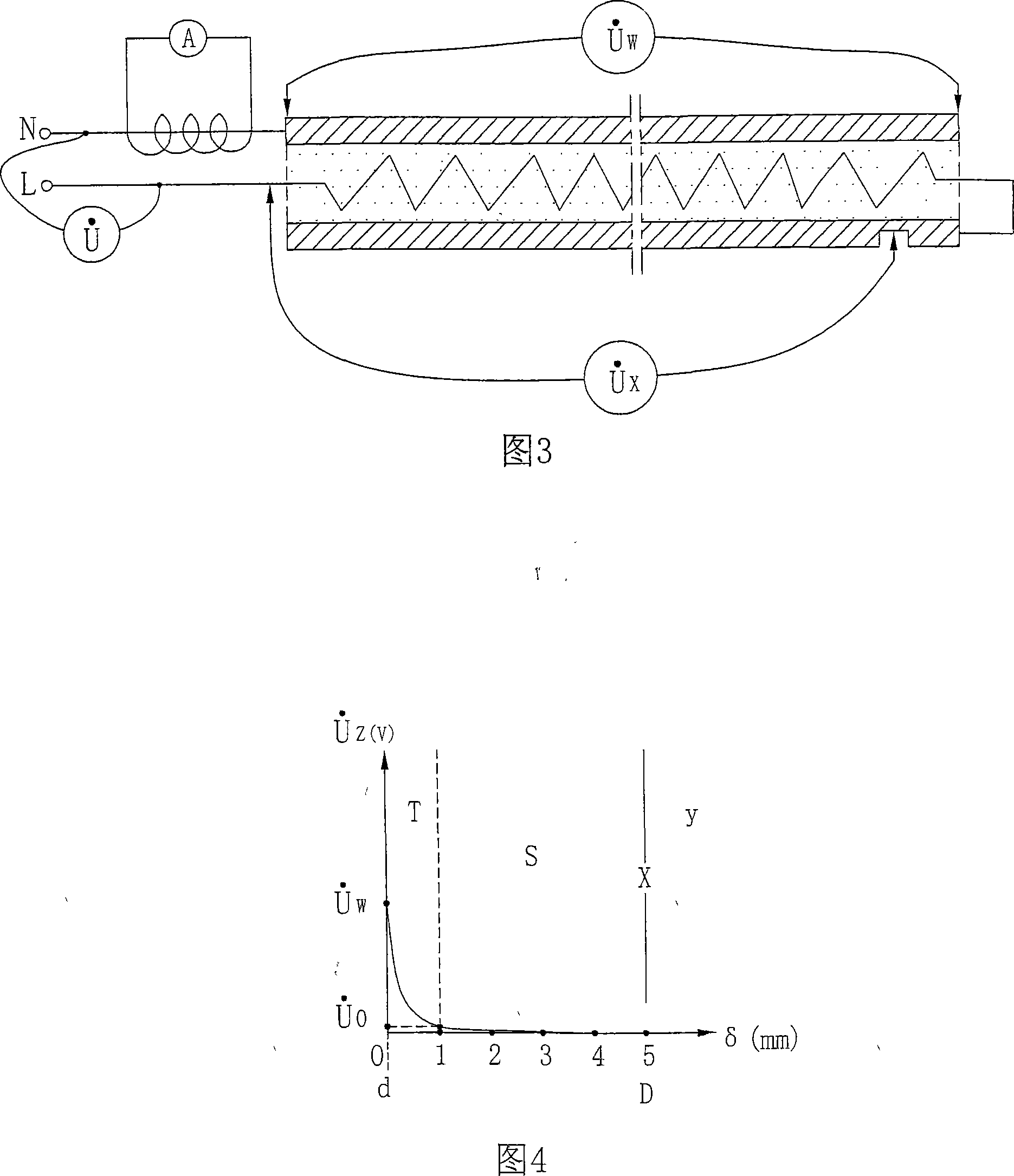

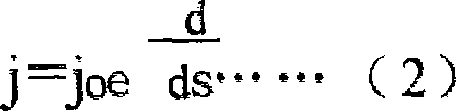

[0041] An industrial electric heating element is used. The specification of 20# carbon steel pipe is 18*3.5mm and the length is 7.5m. There is a right-handed spiral wire in the hole. The material is Cr20Ni80, 1.3mm, and the resistivity is 1.05Ωmm. 2 / m, the outer diameter of the spiral wire is 5mm, the pitch is 8.4mm, the unfolded length is 8.16mm, and the DC resistance before production is 6.45. According to the structure in Figure 1, two lead-out rods are welded at both ends, one lead-out rod is connected to the alloy heating wire, the other lead-out rod is connected, the metal plug is welded to the end of the carbon steel pipe, and the lead-out rod connected to the alloy heating wire is connected to the power frequency power supply Phase line, the surface of the first end of the carbon steel pipe is connected to the neutral line of the power frequency power supply to form an electric circuit to generate heat. The equal length is positioned in the middle of the carbon ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com