An improved drive machine for electric vehicle hub electromotor

A hub motor and transmission mechanism technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of accelerated wear, loose internal parts, increased noise, etc., and achieves extended service life, improved overall performance, and good performance. The effect of homeostasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

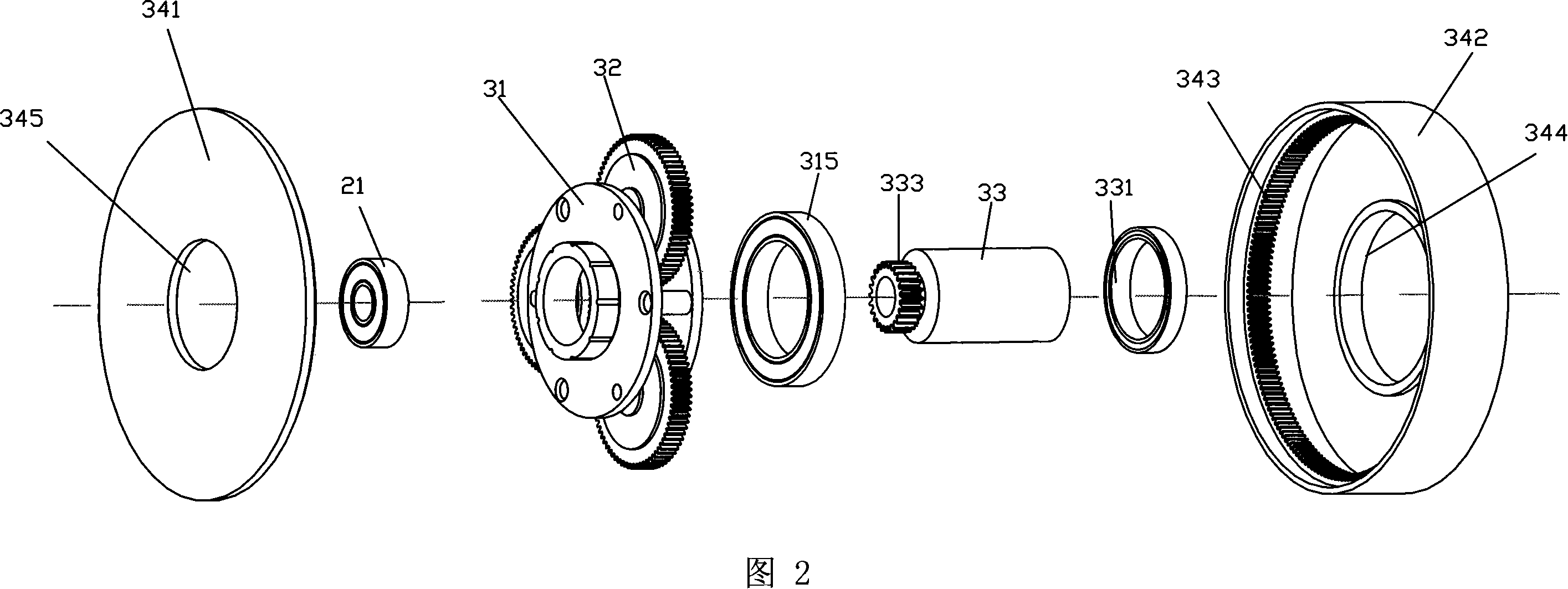

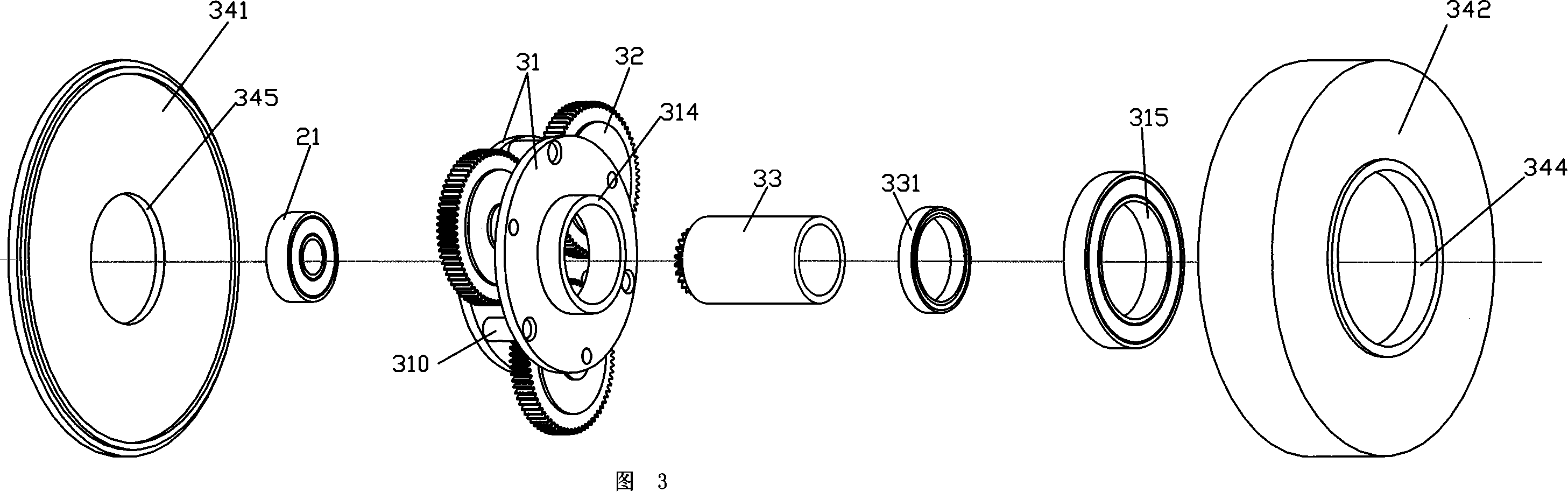

[0013] As shown in Figure 1-4, a transmission mechanism of an improved electric wheel hub motor includes a motor 1, a hub shell, a main shaft 2, a reducer 3 and a clutch, and the stator of the motor 1 and the stator shell 11 are fixedly connected to the main shaft 2, the rotor 12 is accommodated inside the stator and the stator housing 11, the rotor 12 is connected to the reducer 3 through the connecting shaft, the reducer 3 is connected to the hub shell through the clutch, and the reducer 3 is composed of two front and rear positioning discs 31. Three planetary gears 32, several bearings, connecting shafts 33 and a housing 34 are formed. The three planetary gears 32 are symmetrically arranged between the front and rear positioning discs 31. The two ends of the rotating shaft 321 of the planetary gears 32 are fixed Connected on the positioning disc 31, the front and rear positioning discs 31 are also riveted together by rivets 310 to strengthen the reliability of the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com