Modified synthesis technique for disperse red 92

A synthesis process, disperse red technology, applied in the direction of amino-hydroxy anthraquinone dyes, etc., can solve the problems of high production cost, difficult recovery, low recovery rate, etc., and achieve the guarantee of condensation speed and yield, yield and quality Affected, the effect of increasing the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

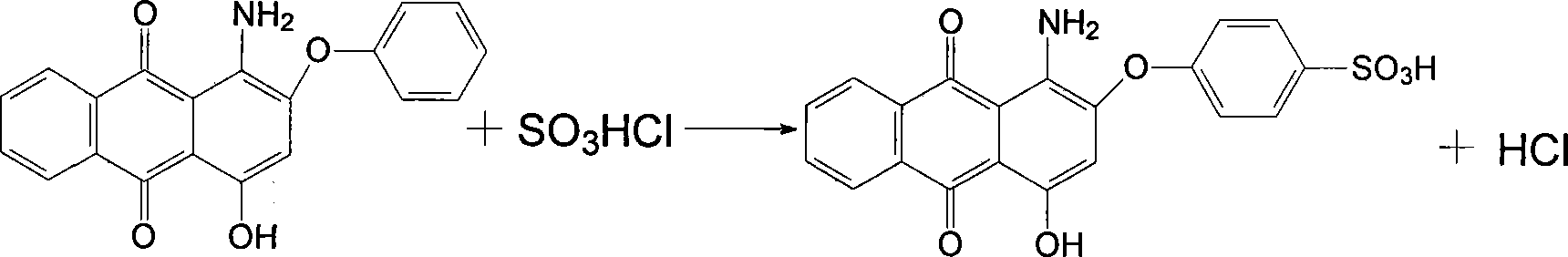

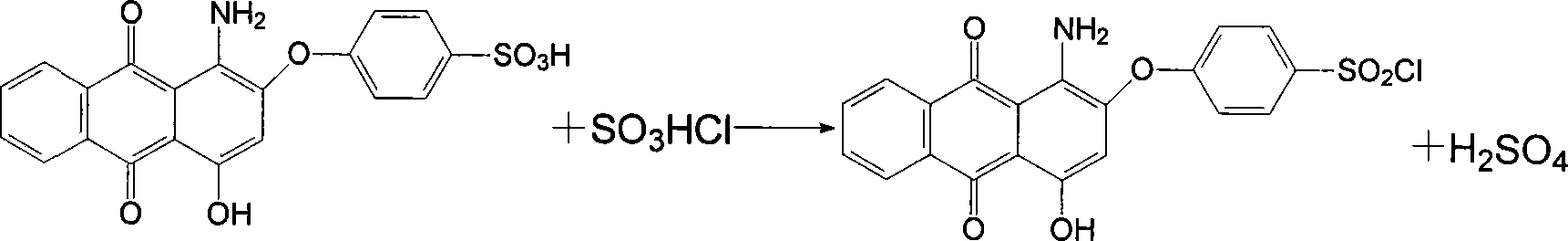

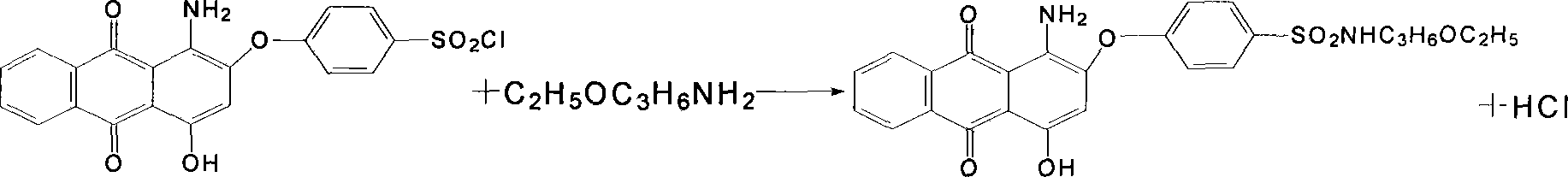

Method used

Image

Examples

Embodiment 1

[0026] Add 500kg of chlorosulfonic acid into a 1000L enamel kettle, control the temperature at 25-35°C for about 2-3 hours and slowly add 150kg of dry product of Disperse Red 60, after the addition is completed, keep it warm at this temperature for 1-2 hours, and then in 2 Slowly add 100kg of thionyl chloride dropwise for ~3 hours. After the dropwise addition, keep it warm at 25-35°C for 7 hours. After the reaction, transfer the material to the isolation kettle, and slowly add ice water dropwise in the isolation kettle for 1-2 hours. 2500kg, continue to stir for one hour and then filter, wash the filter cake with cold water until neutral;

[0027] Add 1500kg of clear water into a 3000L enamel kettle, put in the above-mentioned intermediate filter cake, stir evenly, add 50kg of sodium carbonate and 110kg of γ-ethoxypropylamine, keep it at 35-40°C for 6 hours, and filter after detecting the end point. The cake was washed with hot water at 70-80°C to neutrality, and then discharg...

Embodiment 2

[0029] The amount of chlorosulfonic acid in Example 1 is increased from 500kg to 700kg, and other feeding ratios and operating methods are unchanged to obtain Disperse Red 92 filter cake product 225kg, with a total yield of 97.5% and a content of 99.6%.

Embodiment 3

[0031] Chlorosulfonic acid consumption is increased to 700kg by 500kg among the embodiment 1, sulfur oxychloride is reduced to 80kg by 100kg simultaneously, other feeding ratio and operating method are constant, obtain disperse red 92 filter cake product 218kg, total yield is 94.5%, the content is 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com