Pneumatic load-removing plastic-sticking guiding rail

A guide rail and plastic sticking technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of reducing the surface processing quality of the workpiece, high processing accuracy of the static pressure guide rail, and reducing the driving power of the worktable. Improve the quality of the machined surface, improve the machining accuracy, and avoid the effect of guide rail scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

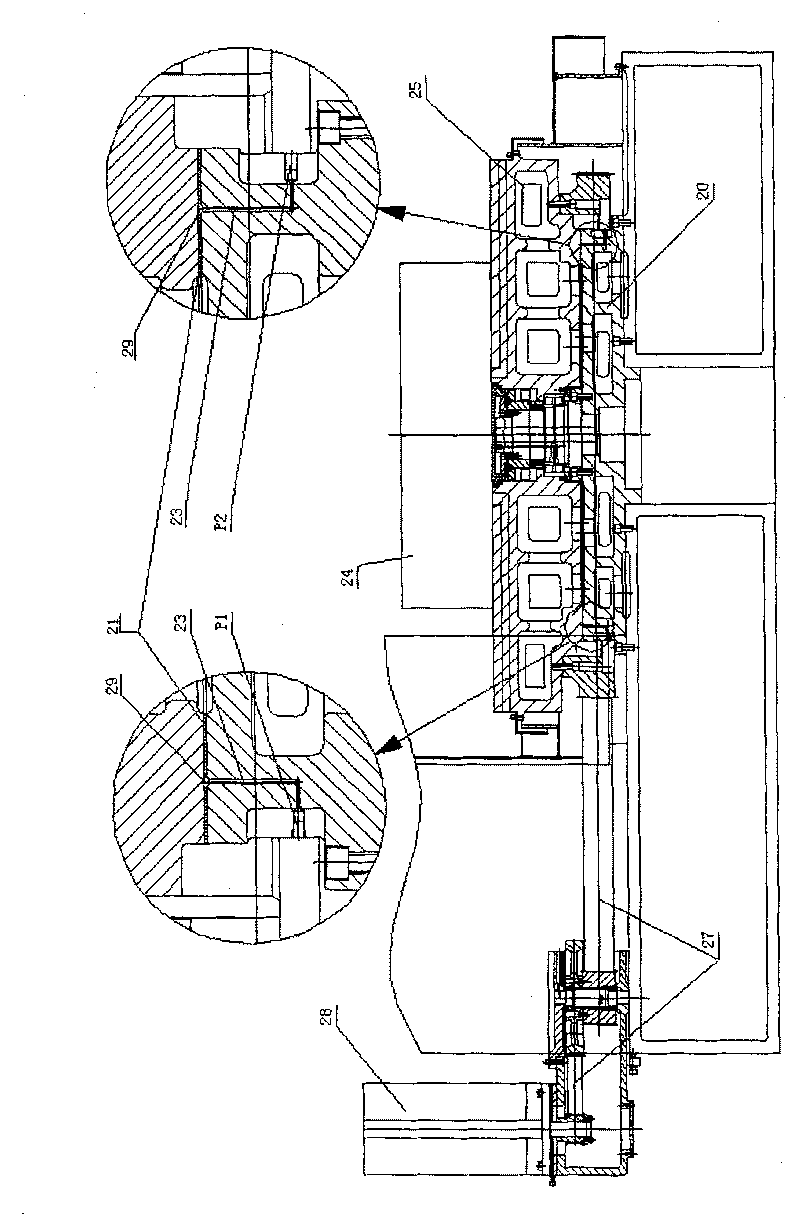

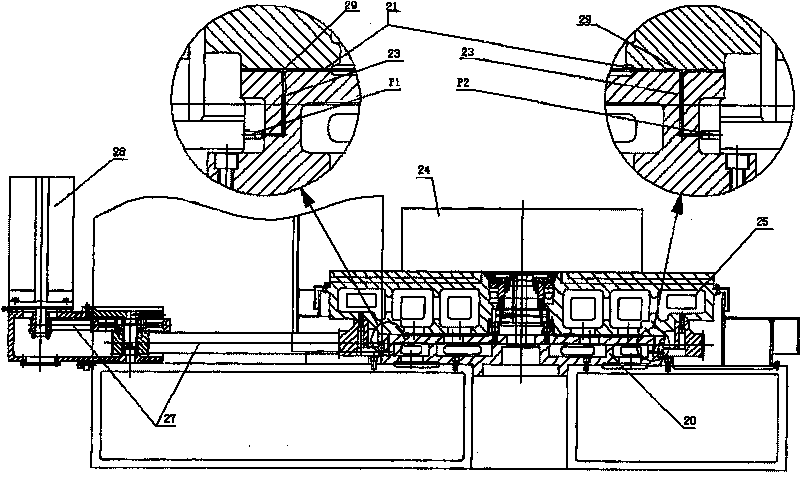

[0018] Such as figure 1 , figure 2 As shown, the present invention provides an air pressure unloading plastic-coated guide rail, which includes: a guide rail 20 ;

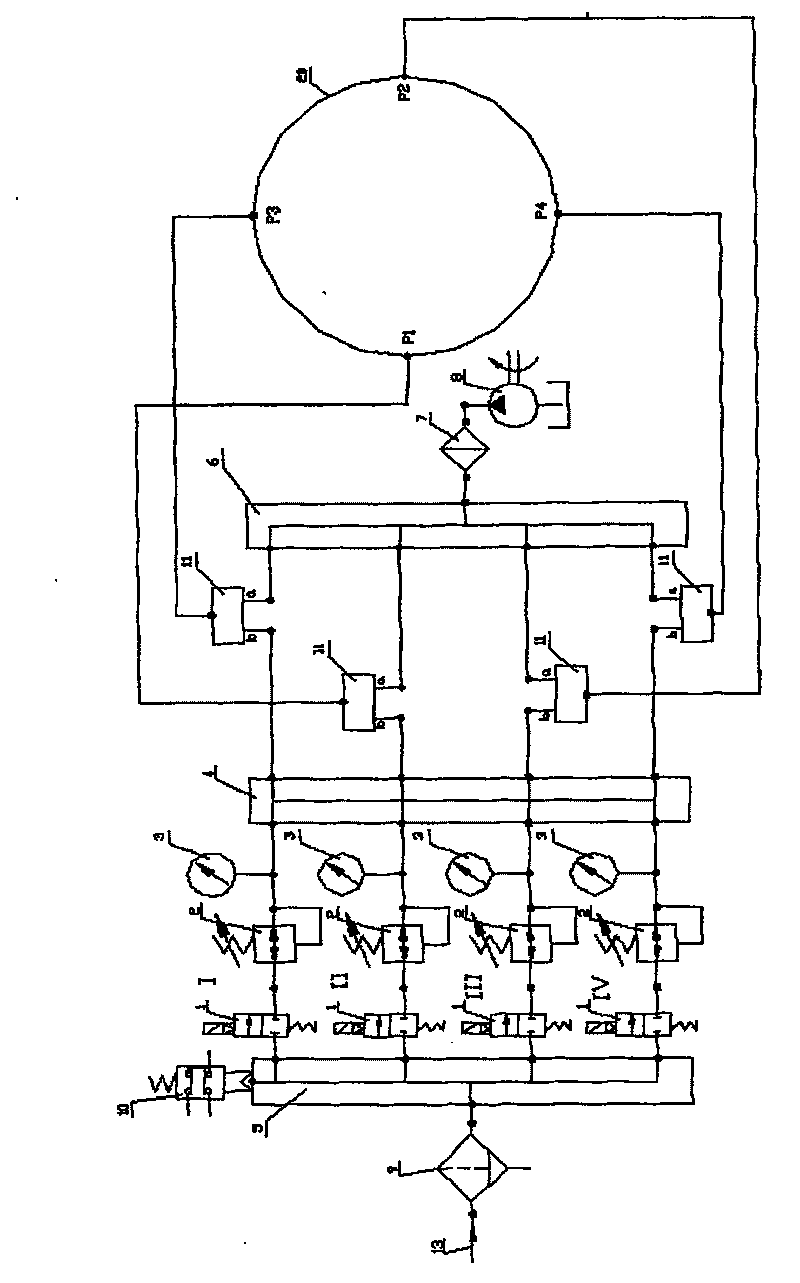

[0019] The surface of the guide rail 20 is bonded with a guide rail soft belt layer 21; oil and gas inlets P1, P2, P3, and P4 are arranged on the guide rail soft belt layer 21; 11, the gas regulating oil valve 11 has an oil circuit input terminal a and an air circuit input terminal b, the oil circuit input terminal a is connected in series with the oil filter 7 and the oil pump 8; the gas circuit input terminal b is connected in series The pressure gauge 3, pressure reducing valve 2, electromagnetic valve 1, and air filter 9 are connected to an air source 13, and the node between the air filter 9 and the electromagnetic valve 1 is connected to a pressure relay 10.

[0020] The guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com