Roller type medium speed mill

A medium-speed, roller-type technology, applied in grain processing, etc., can solve the problems of poor adaptability of grinding materials, heavy maintenance workload, and short life of wearing parts, so as to reduce the weight of the mill, prolong the service life, and reduce the outlet The effect of velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

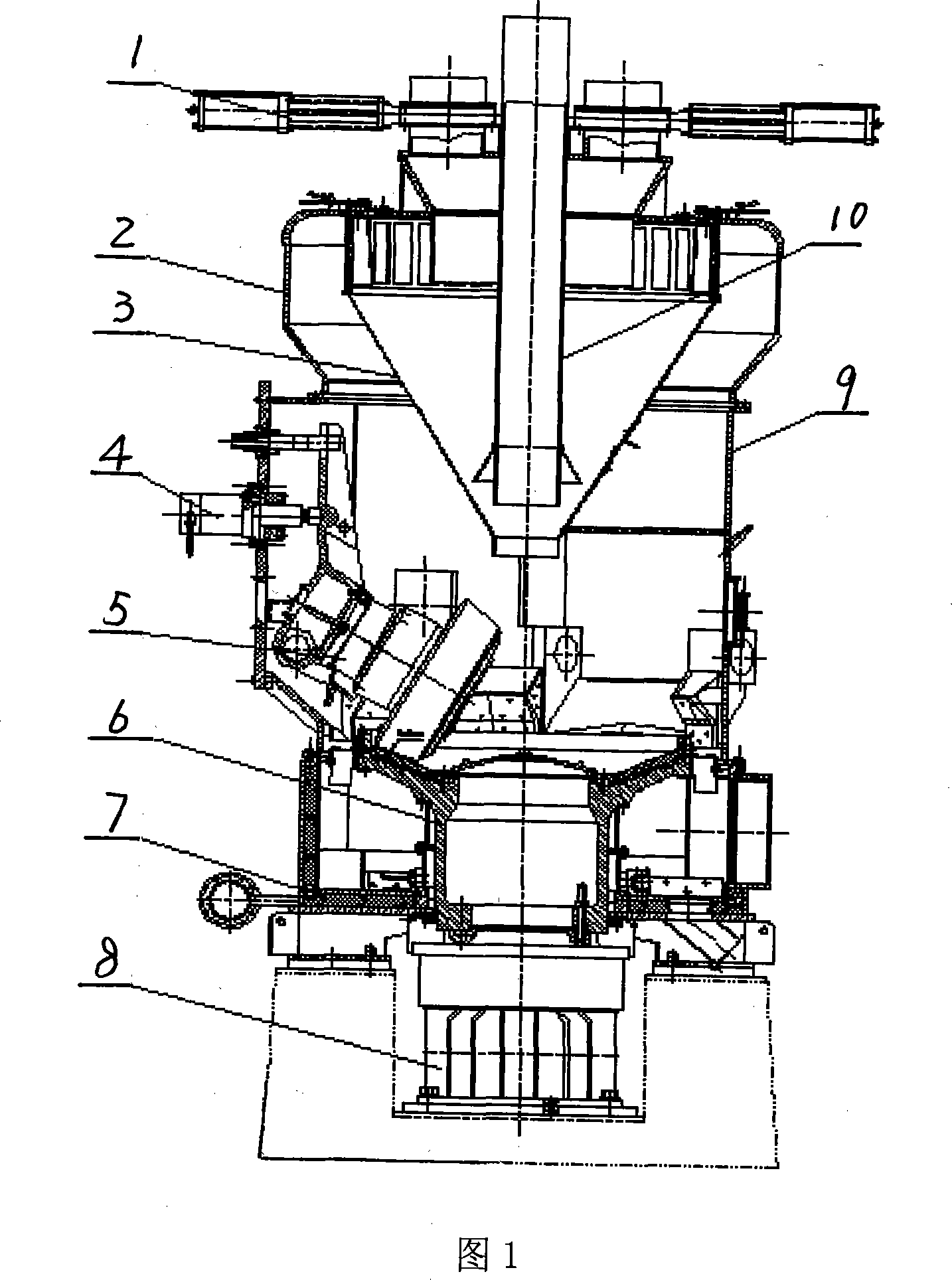

[0009] Referring to the accompanying drawings, it is a roller-type medium-speed mill. The working principle is that the grinding bowl and impeller device rotate clockwise under the drive of the reduction box. After the material falls into the grinding bowl from the central coal drop pipe, it is Moving radially outward, a material bed is formed on the grinding bowl, and the material bed passes under the rotating grinding roller device; at this time, the grinding force generated by the loading device is applied to the material through the rotating grinding roller , the material is ground into powder between the bowl liner and the grinding roller, and the material moving radially and circumferentially carries the crushed powder across the edge of the bowl and enters the conveying medium channel. The conveying medium is typically hot air , has three main functions: first, it provides the necessary power for the mill to separate the powder; second, the hot air continuously dries the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com