Method and device for self-cleaning and voltage-dependent electro static filtering

An electrostatic filtering and cleaning technology, which is applied in the field of electromagnetic filtering devices (generating toxic dust or non-dust) industrial devices, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

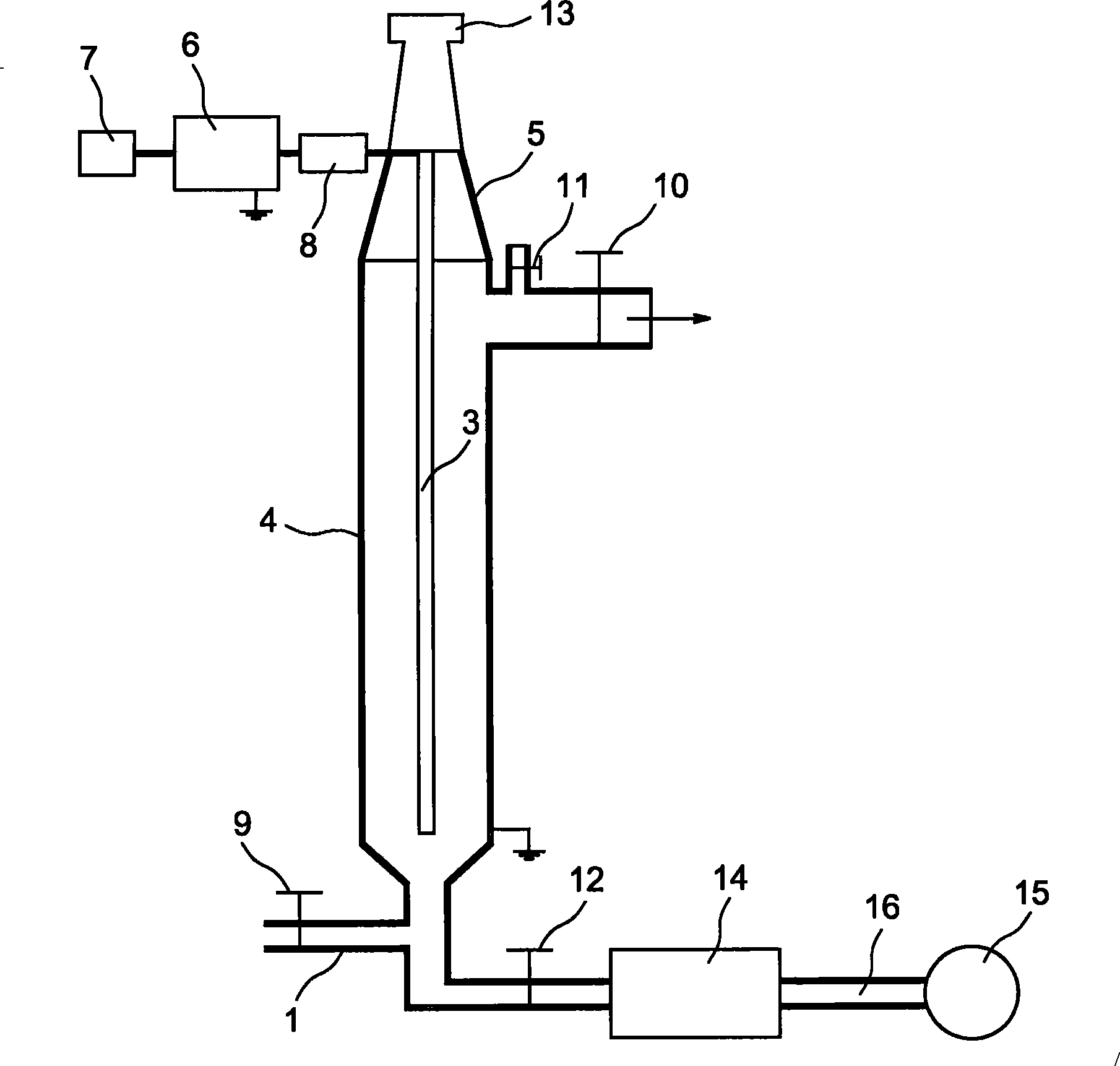

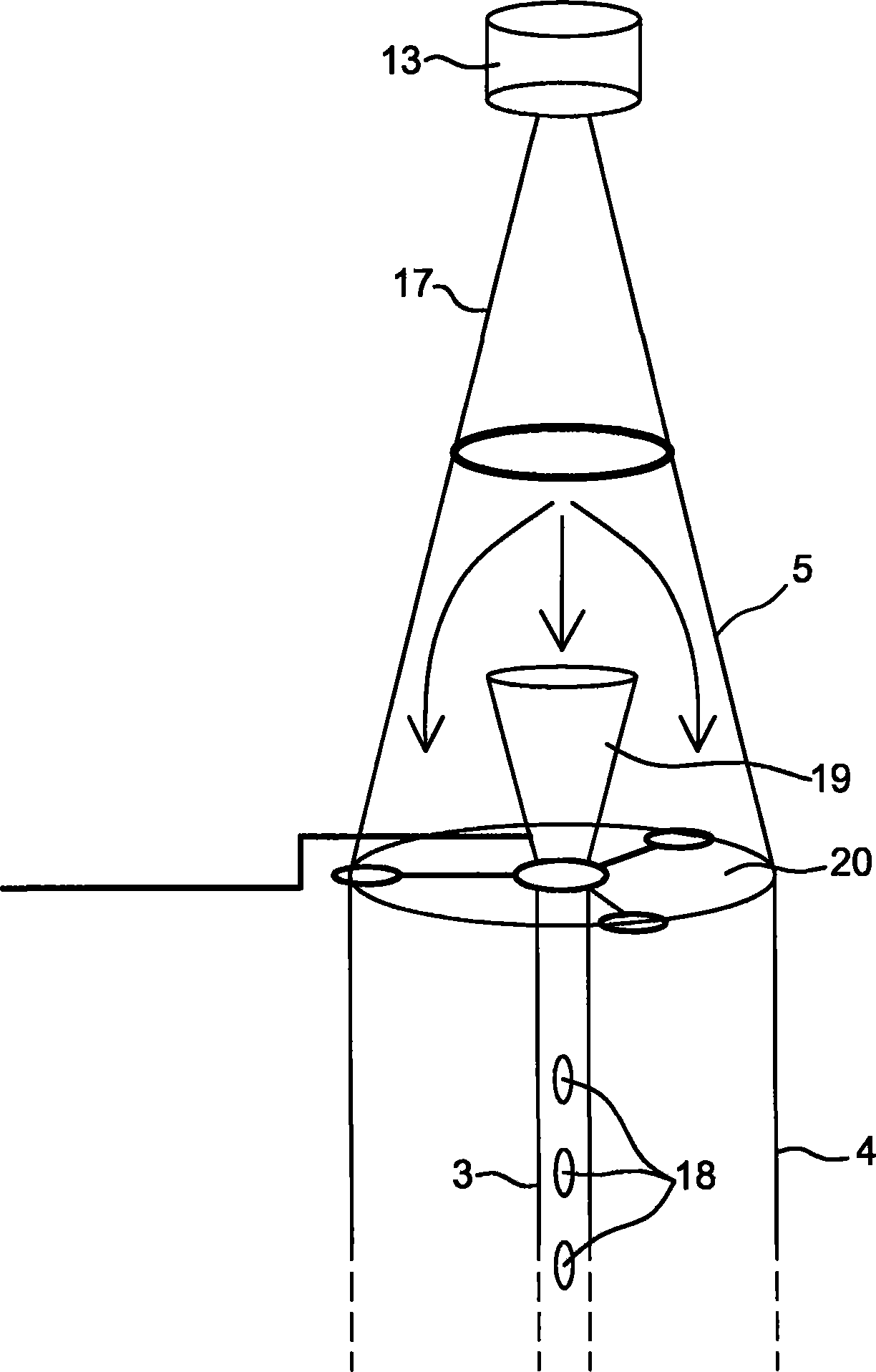

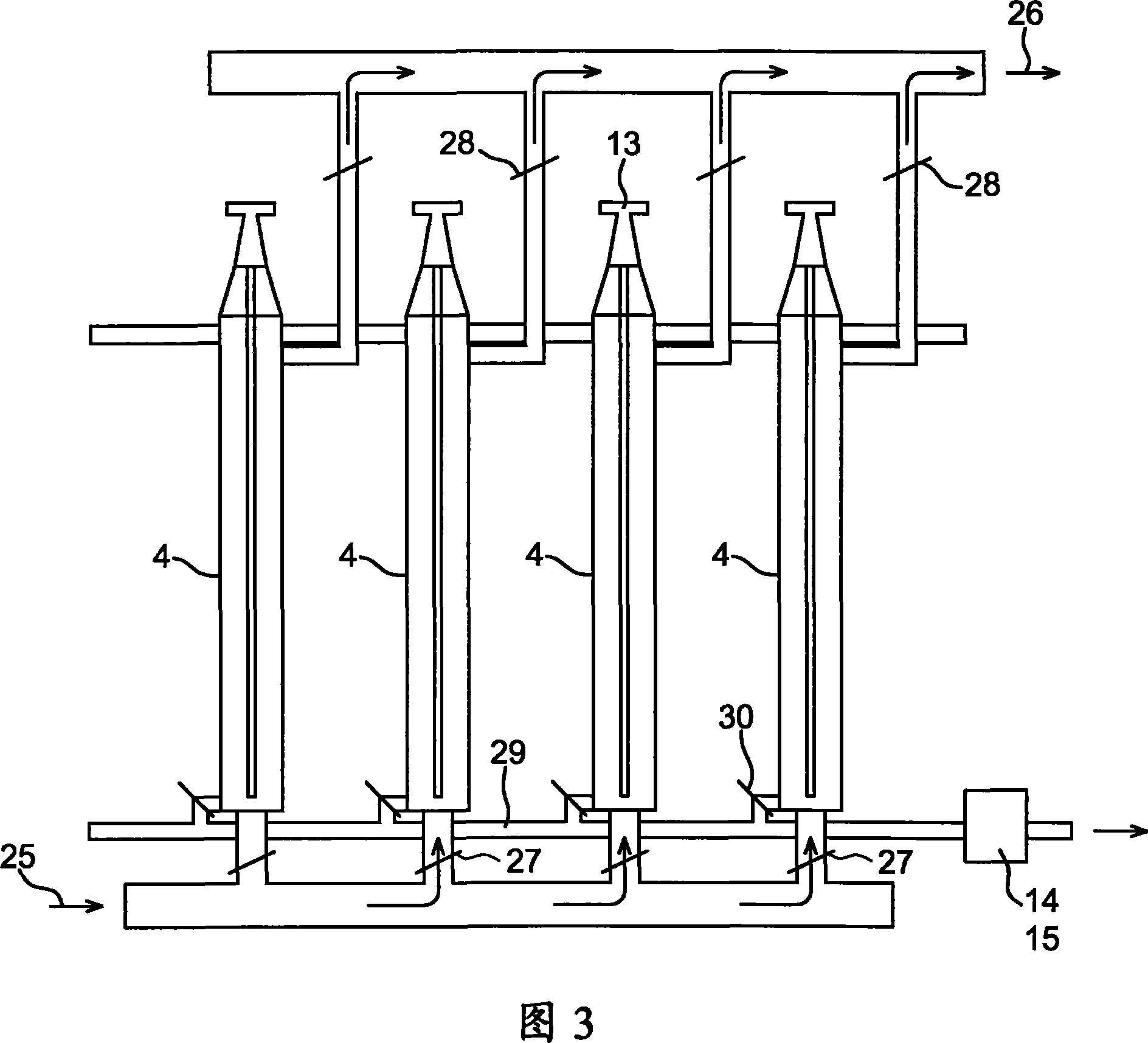

[0021] refer to figure 1 , the filtering method and device according to the present invention repeats the standard pipe structure in which the dust-laden fluid is introduced through the inlet 1 arranged at the lower part of the pipe 4, the internal temperature of which is lower than 140°C. Inside the tube 4 there is a high voltage electrode 3 supported by an isolator 5, which occupies most of the length of the tube 4, forming a grounded counter-electrode. The fluid to be filtered is discharged from the outlet 2 arranged in the upper part of the pipe 4 . If the air flow is relatively high, the electrode 3 must be rigid and stably attached.

[0022] A high voltage generator 6 powers the electrodes 3 and is connected to control means 7 comprising a computer capable of detecting the arc generated between the high voltage electrodes 3 and the tube 4 . By means of the control device 7 it is possible to control the wave generator 13 (to be described later), for example with respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com