Optical board and the backlight module using same

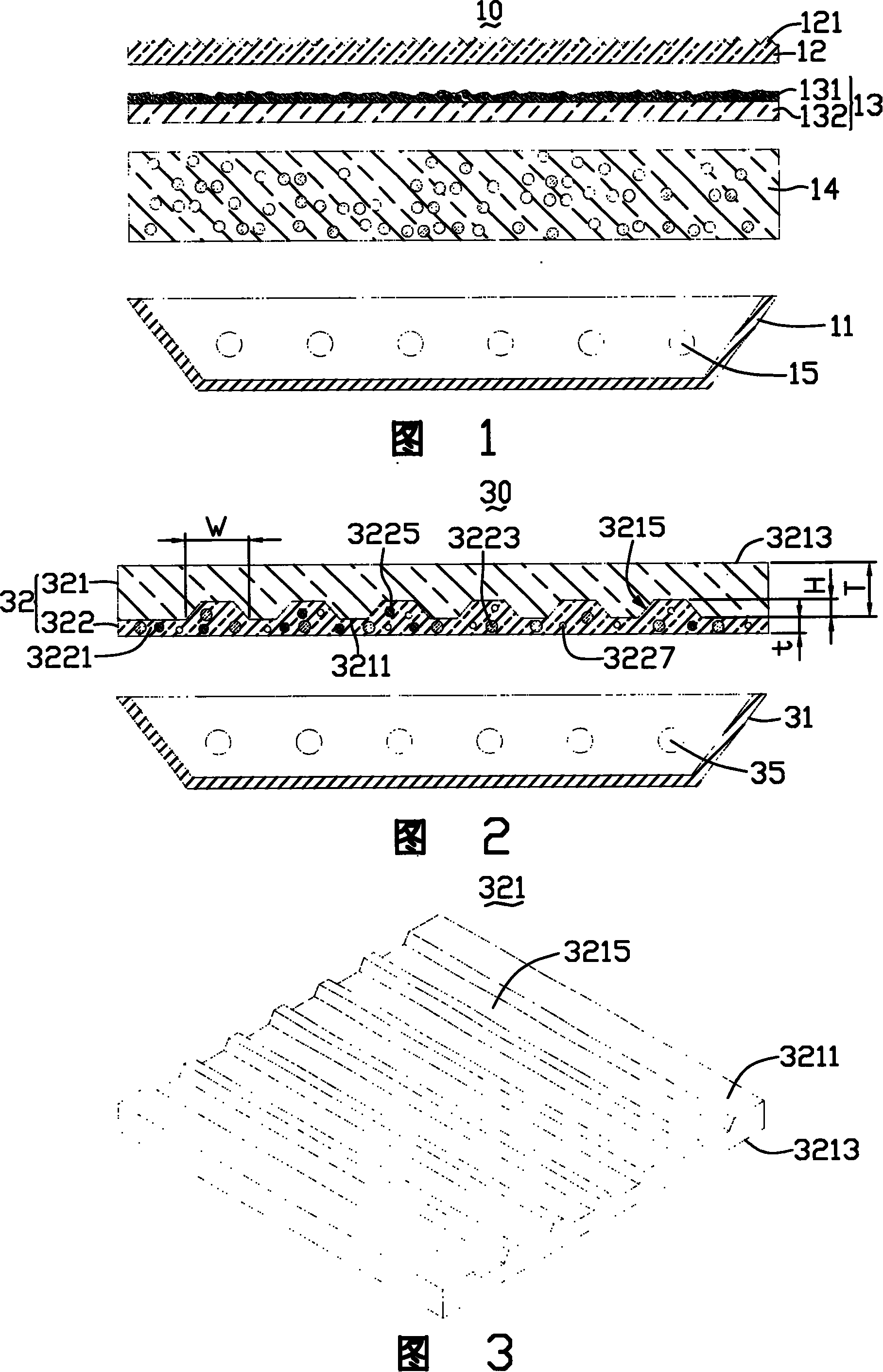

A technology for optical boards and light-emitting surfaces, applied in the field of optical boards, can solve problems such as increasing manufacturing costs and increasing the thickness of backlight module 10, and achieve the best uniformity of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The optical plate of the present invention and the backlight module using the optical plate will be described in further detail below in conjunction with the accompanying drawings and multiple embodiments.

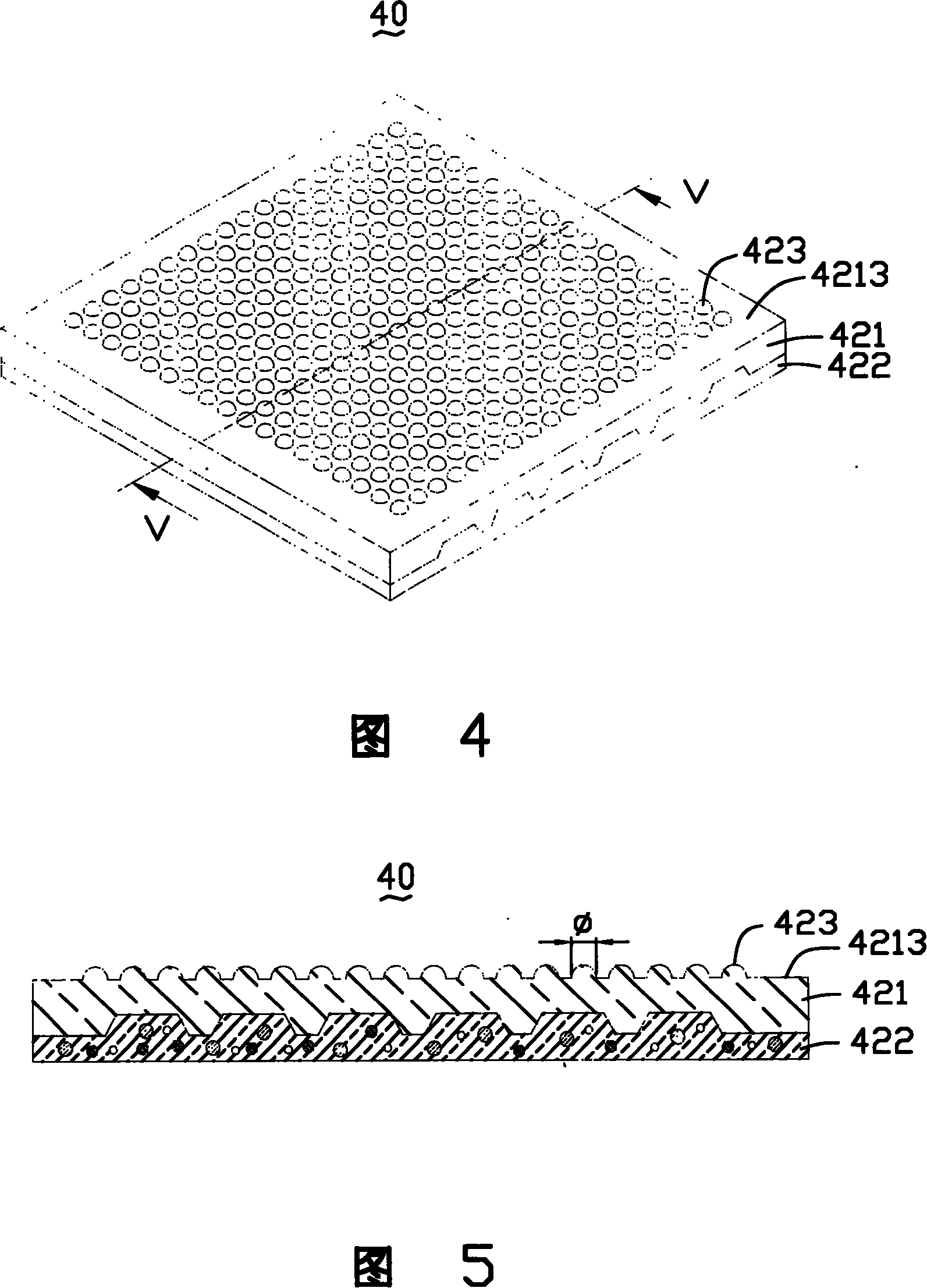

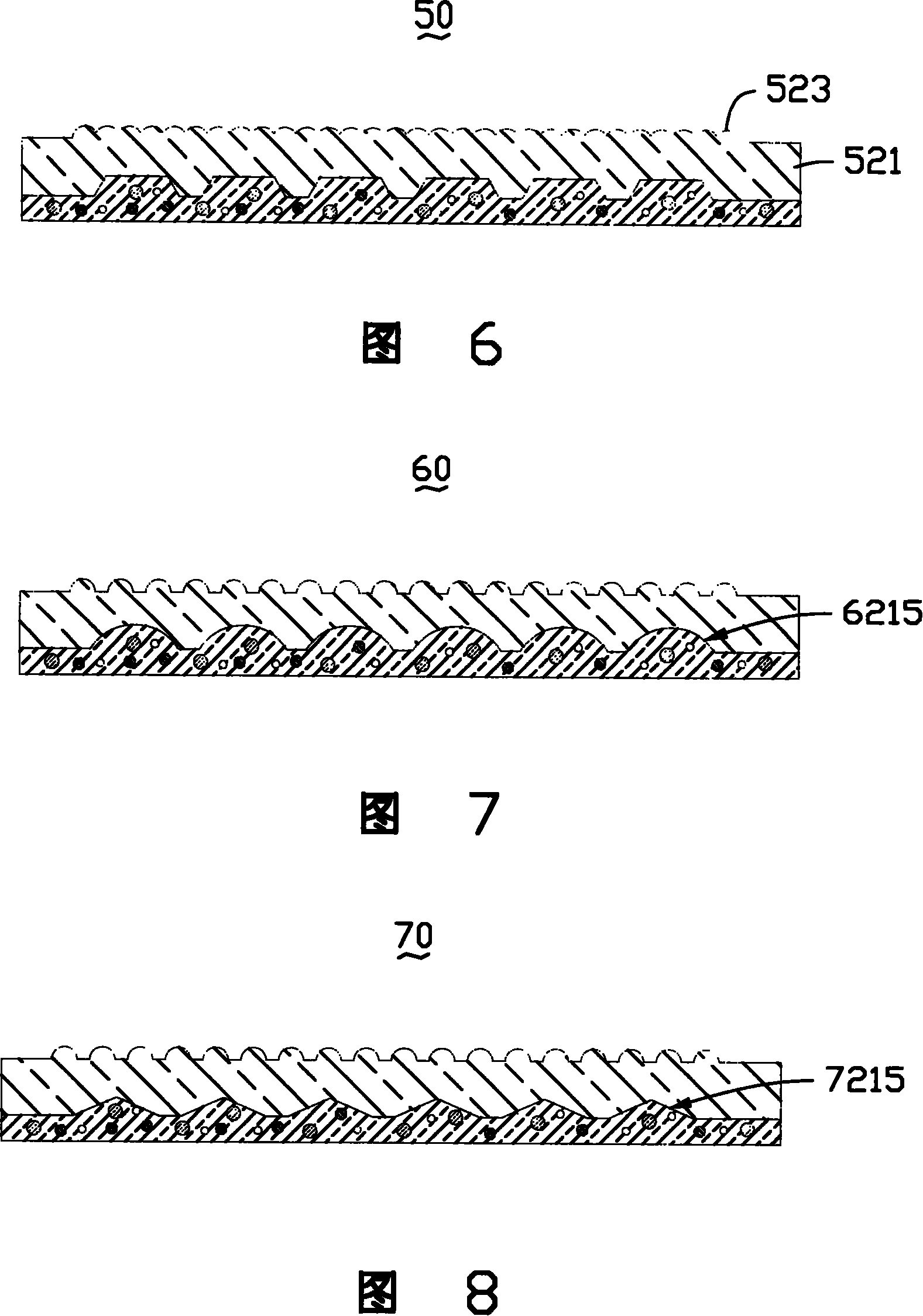

[0018] Please refer to FIGS. 2 and 3 together. The first preferred embodiment of the present invention provides a backlight module 30 which includes a reflective plate 31, a plurality of lamp tubes 35 and an optical plate 32. The optical plate 32 includes a transparent substrate 321 and a diffusion layer 322. The transparent substrate 321 includes a light-emitting surface 3213 and a connecting surface 3211 opposite to the light-emitting surface 3213. The connecting surface 3211 is formed with a plurality of elongated grooves 3215. The diffusion layer 322 is attached to the connecting surface 3211 and fills the plurality of grooves 3215. The reflecting plate 31 is opposite to the optical plate 32 and the diffusion layer 322 faces the reflecting plate 31. The lamp tube 35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com