Claw-free ratchet mechanism

A pawl ratchet and gear technology, applied in the field of intermittent motion mechanism, can solve the problems of lack of pioneering, weak shaft pin, skipping teeth, etc., and achieve the effect of easy manufacture, simple mechanism and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

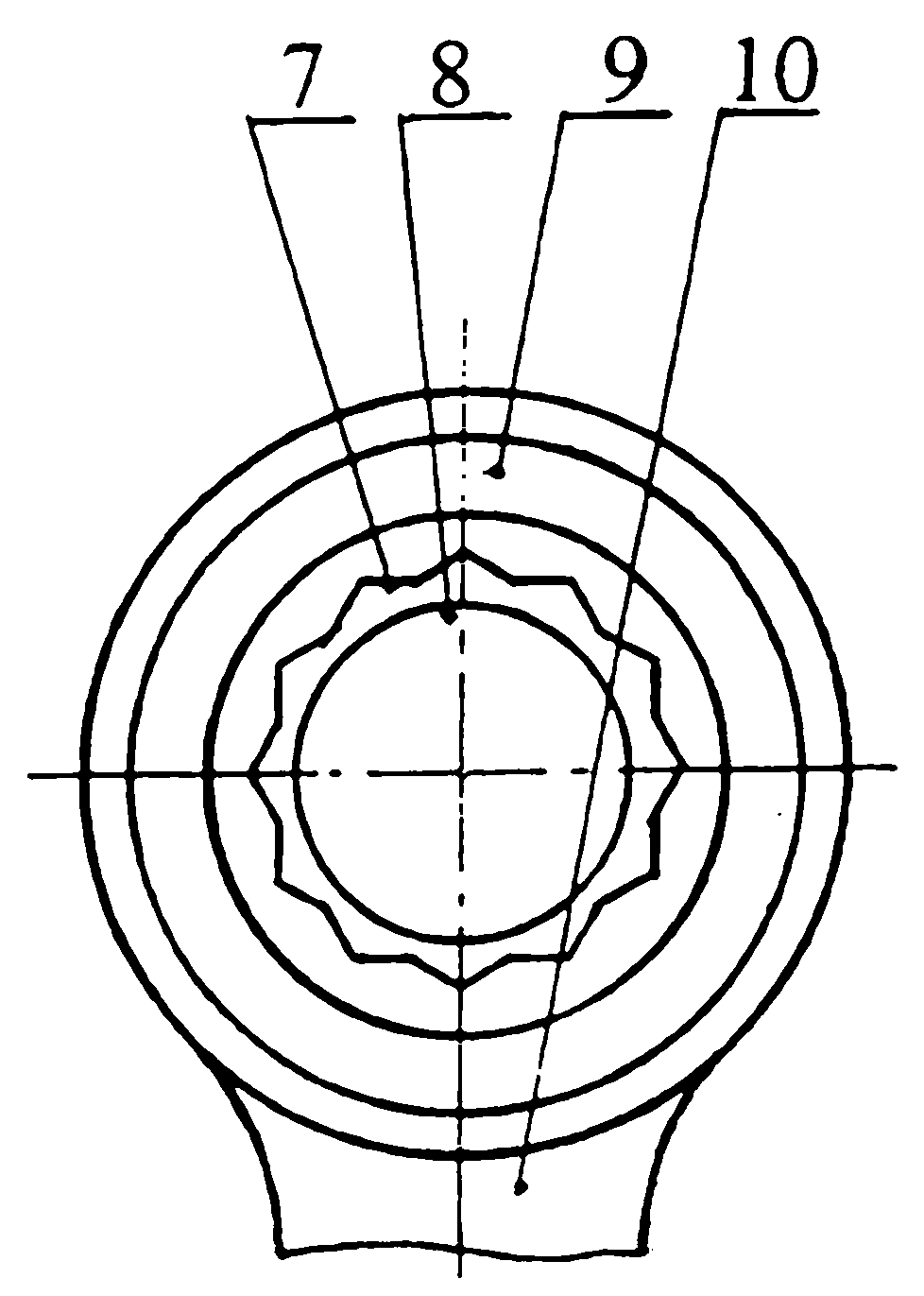

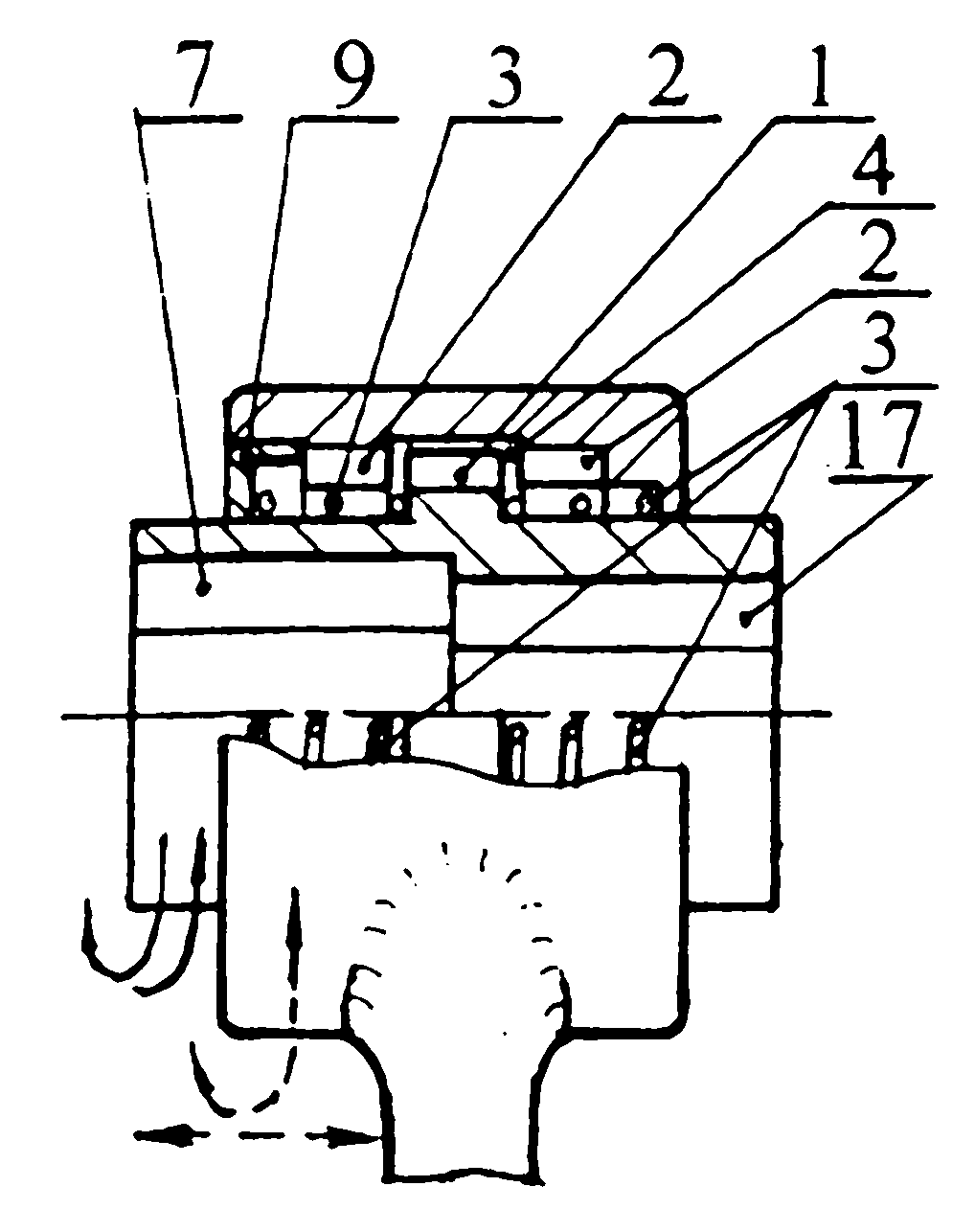

[0013] figure 1 , figure 2 Among them, a space 4 is provided beside the external gear 1 and the internal gear 2, which have the same number of teeth and each tooth meshes with each other, and a spring 3 is provided between one end surface of the external gear 1 and one end of the internal gear 2, and the spring 3 can make the meshing The external gear 1 and the internal gear 2 are pushed apart and placed in the space 4 respectively. After the separation, the external gear 1 and the internal gear 2 can rotate independently.

[0014] The external gear 1 and the internal gear 2 may also be an external gear set 5 and an internal gear set 6 composed of several external gears and internal gears with the same number of teeth, respectively axially spaced and stacked as a whole, and the external gear set 6. The gears on the group 5 and the internal ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com