Touch control type flat-panel display electric pole structure

A flat-panel display and touch electrode line technology, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve the problems of complicated control methods, many components, and reduced reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

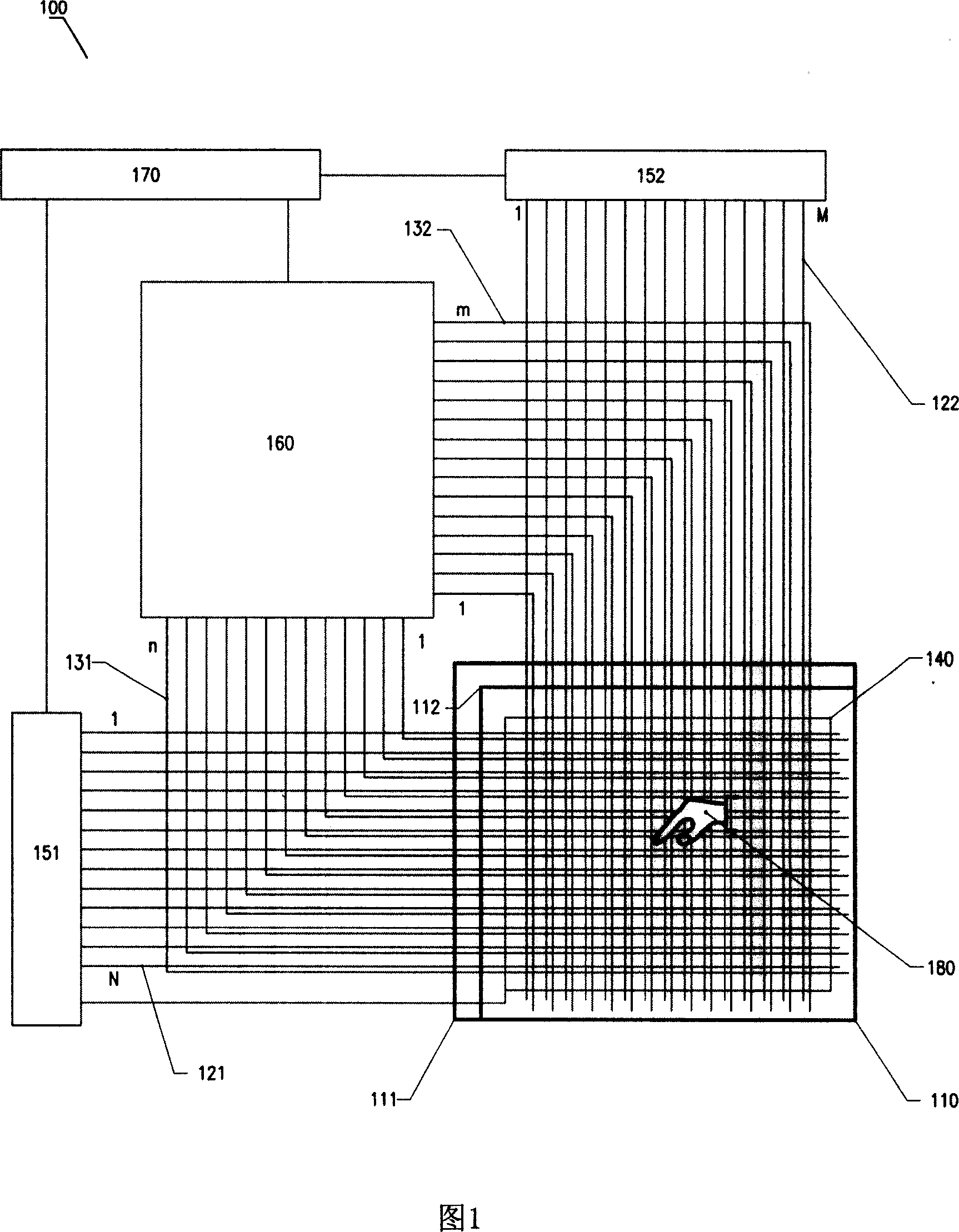

[0024] One of the embodiments of the present invention is shown in FIG. 1 : a touch-sensitive liquid crystal display 100 for detecting the leakage current of touch electrode lines. The liquid crystal display 100 has a TFT-LCD screen 110, the TFT-LCD screen has a TFT array substrate glass 111 and a common electrode substrate glass 112, and the TFT array substrate glass 111 has N display scanning electrodes 121 and M display signal electrodes 122. N rows of metal touch electrode lines 131 and m columns of metal touch electrode lines 132 are prepared 111 on the glass of the TFT array substrate. The touch electrode lines 131 and 132 have lead-out pins from the same side as the display electrodes 121 and 122 respectively, and the common electrode There is an ITO common electrode 140 on the substrate glass 112 . The display scan electrodes 121 of the liquid crystal display screen 110 are connected to the display driving circuit 151 , the display signal electrodes 122 are connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com