Novel semi-trailer with automatic synchronization steering mechanism

A steering mechanism and automatic synchronization technology, which is applied to steering mechanisms, trailer steering mechanisms, and steering mechanisms of front and rear tandem vehicles. Different problems, change the force structure of the trailer, etc., to achieve the effect of facilitating the promotion and implementation, avoiding sliding friction, and improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

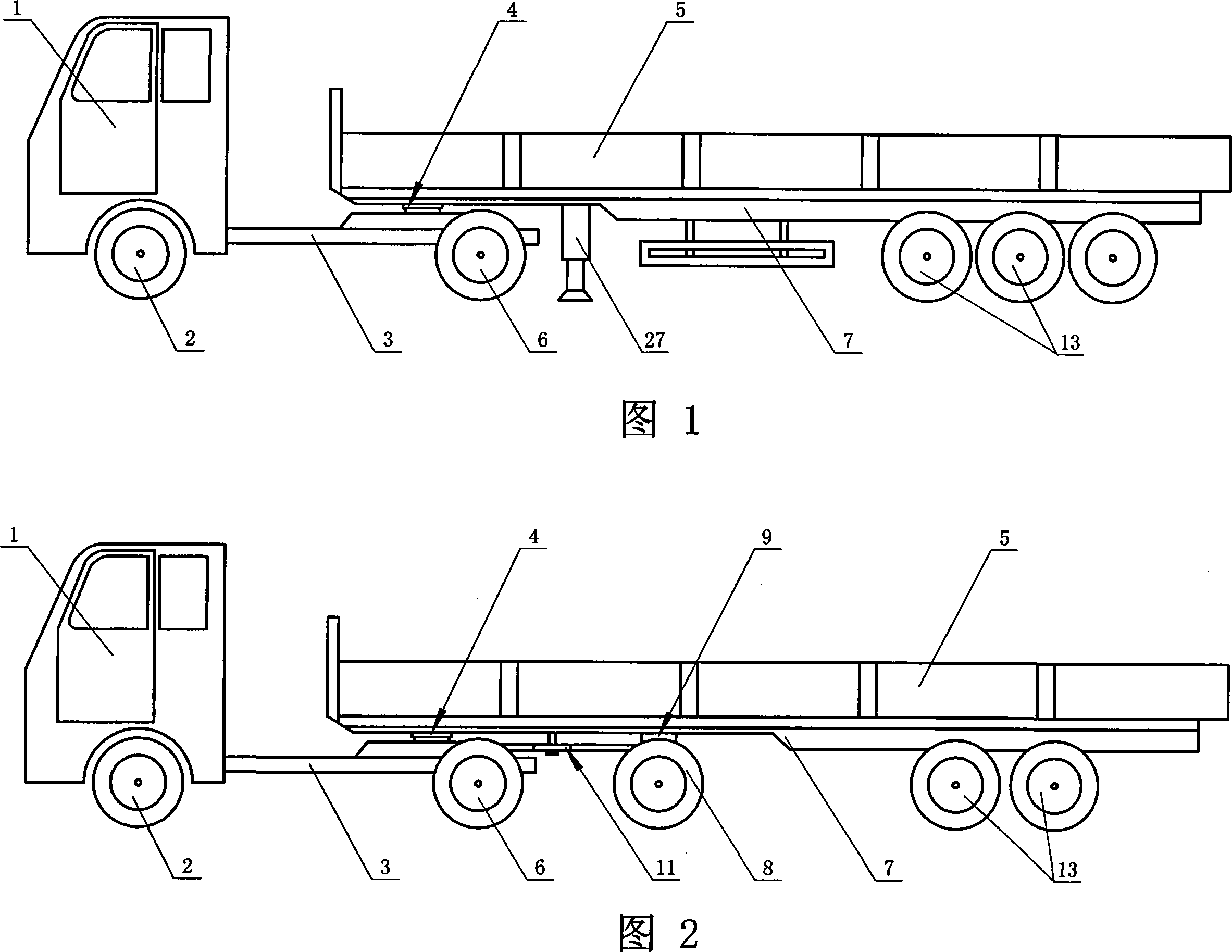

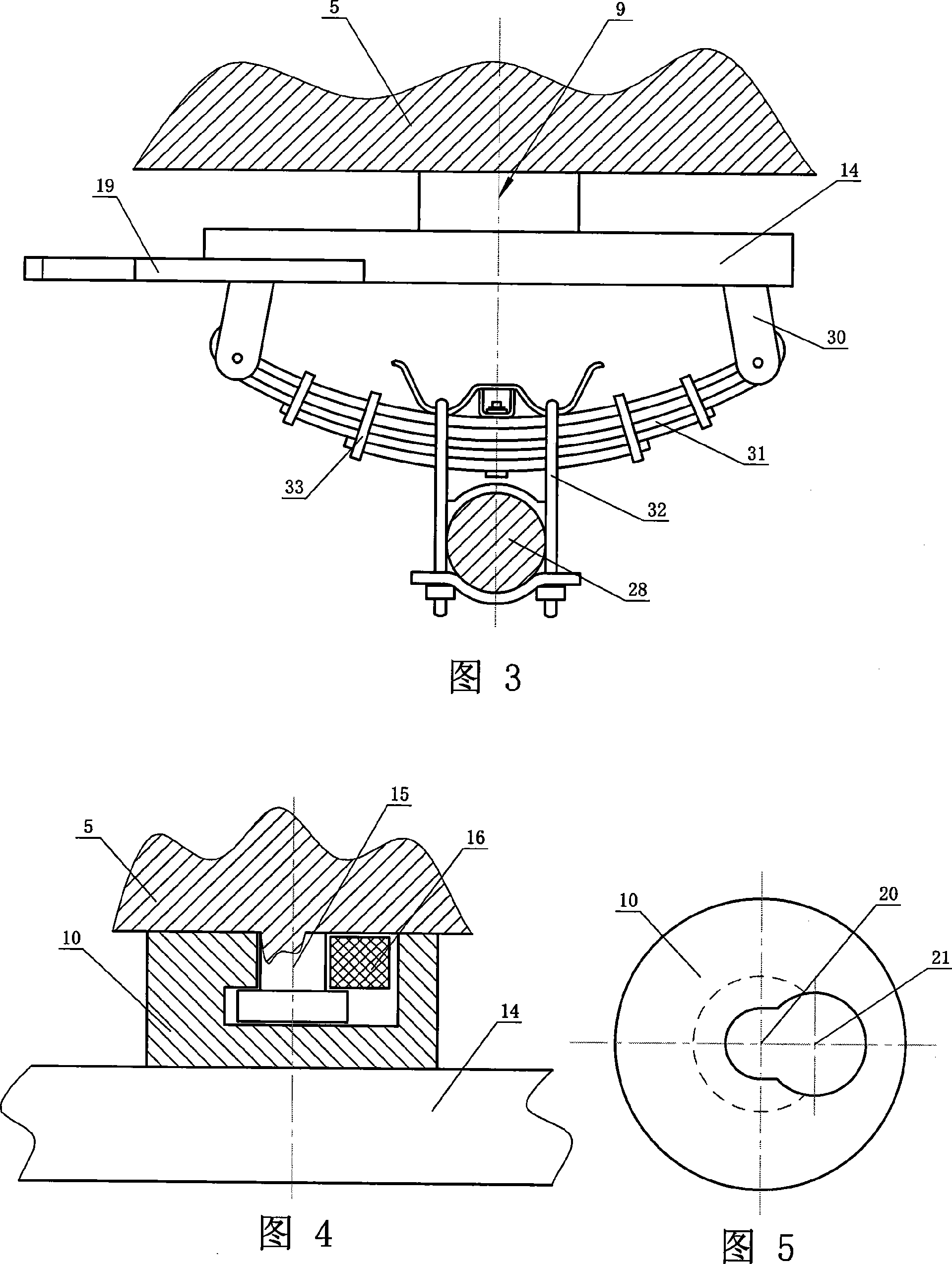

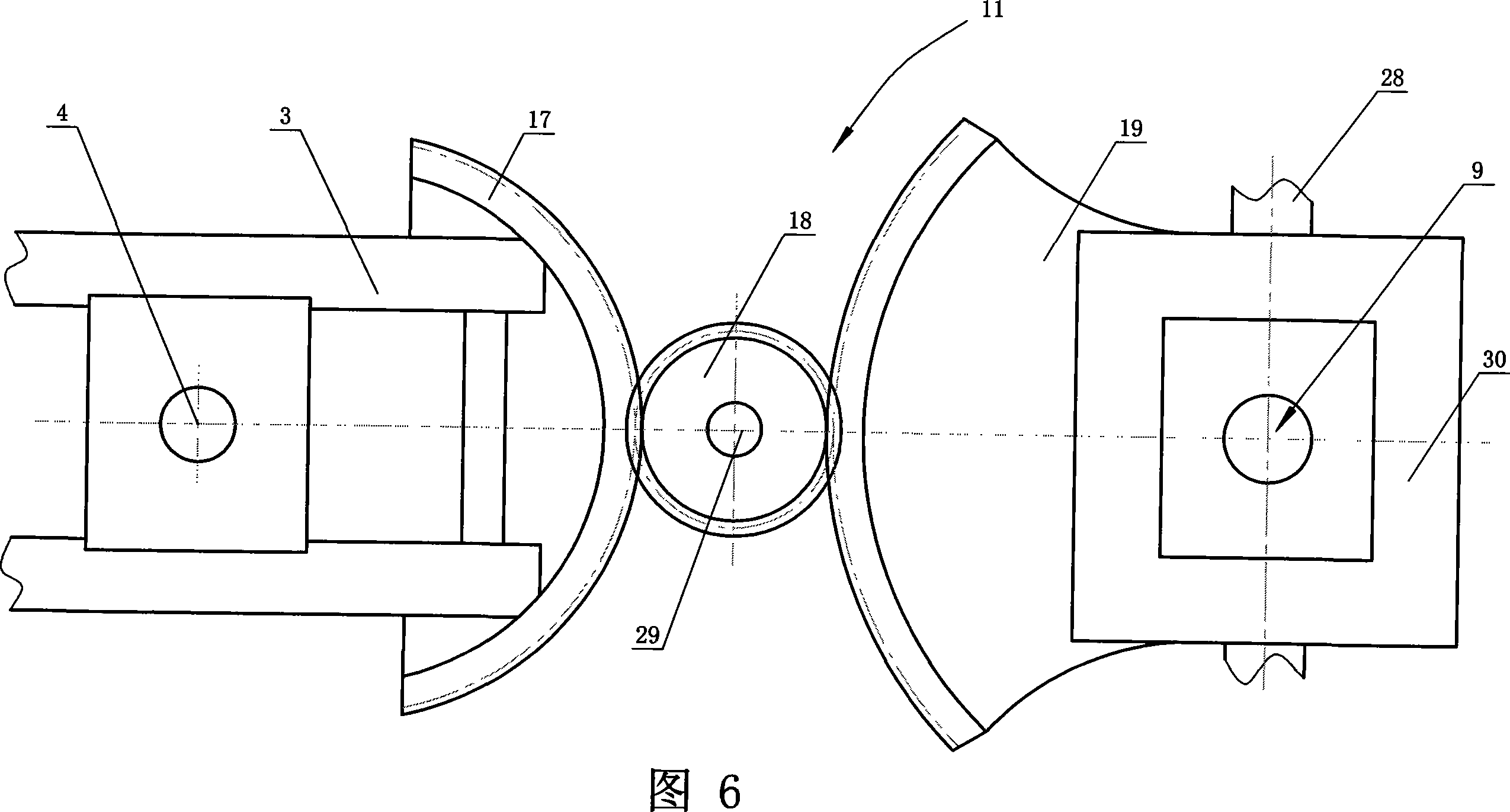

[0038] Embodiment 1: Referring to Figures 1-6, a new type of semi-trailer with an automatic synchronous steering mechanism, including a main vehicle 1, a traction girder 3 connected to the main vehicle 1 and a power wheel 6 on the traction girder 3, and the traction girder 3 The semi-trailer 5 is movably connected with the rotating connection device 4, and the semi-trailer load-bearing wheel 8 is installed on the rear end of the bottom of the semi-trailer beam 7, and the front load-bearing wheel 13 of the semi-trailer is installed on the front end of the bottom of the semi-trailer beam 7. The front load-bearing wheel of the semi-trailer Wheel 13 is installed on the bottom of semi-trailer frame 7 by load-bearing wheel rotating mechanism 9, and is connected with the synchronous steering mechanism 11 of gear transmission between traction frame 3 and front load-bearing wheel rotating mechanism 9.

[0039] The load-bearing wheel rotating mechanism 9 is a rotatable structure fixed on...

Embodiment 2

[0043] Embodiment two: referring to Fig. 7, Fig. 8, numbering is identical with embodiment one, and meaning is identical, does not repeat, and difference is: guide wheel 18 radiuses become larger, make the radius of main vehicle gear 17, turning mechanism gear 19 reduce , the 19 wheels of the rotating mechanism teeth become a full circle.

Embodiment 3

[0044] Embodiment 3: Referring to Fig. 9 and Fig. 10, the numbering is the same as that of Embodiment 1, the meaning is the same, and it will not be repeated. The concave hole on the traction disc matches the maximum outer diameter of the "children" structure, and a fixed retaining ring 34 is provided at the edge of the concave hole of the traction disc. After the retaining ring 34 is installed in place, its surroundings are fixed with Bolt 35 is fixed. The circumferential flange 37 of the traction pin 15 with a "child"-shaped longitudinal section is matched and installed in the annular concave edge 38 formed by the traction disc 10 and the retaining ring 34, and the traction disc 10 can rotate along the axis of the traction pin 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com