Station adjusting machine automatic drive system

A technology of automatic driving and machine adjustment, which is applied in the fields of railway car body components, locking devices in stations, railway signals and safety, etc., can solve problems such as the automatic driving system for machine adjustment in a complete sense, and reduce the time for confirming signals, The effect of improving operation accuracy and reducing the number of drivers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

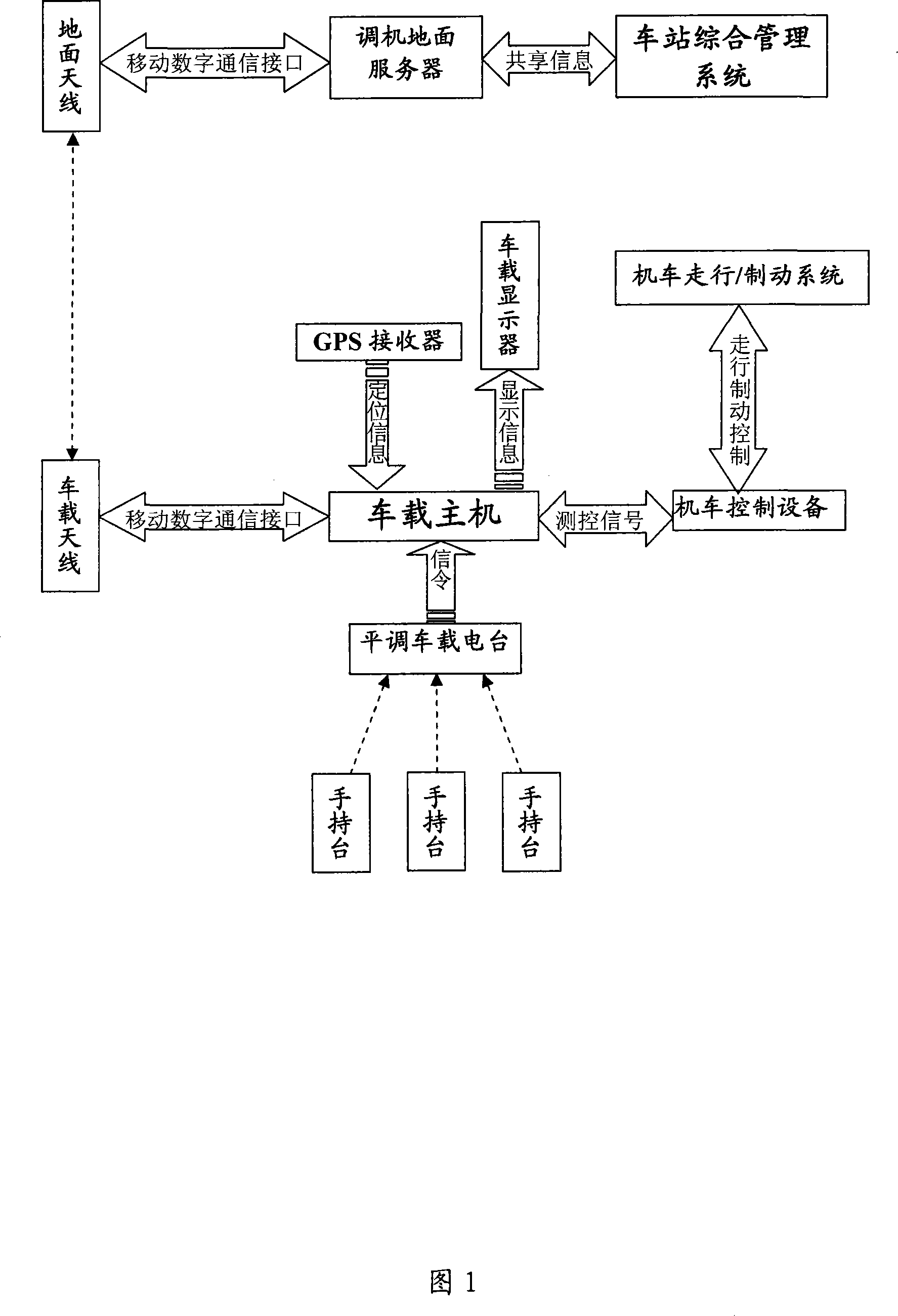

[0026] The functional block diagram in Fig. 1 shows the automatic driving system for dispatching machines at a station according to a preferred embodiment of the present invention. As can be seen from Figure 1, the system includes four parts: ground equipment, communication equipment, vehicle equipment and leveling equipment. The ground equipment is responsible for collecting, sorting and organizing various shunting information on the shared information database platform of the station management system, which includes shunting and shunting plan instructions, station indications including shunting routes, Vehicles existing on the line), and at the same time provide the information platform with information such as the dynamic position of the dispatching machine tracking and positioning, the actual running direction and speed of the locomotive, and the status of on-board equipment, for sharing by the station management system or other subsystems. The communication equipment ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com