Heat quantity reclaiming type electric heater

An electric heater and heat recovery technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large heat load of stainless steel water pipes, easy scaling of water pipes, and fire hazards, so as to achieve no fire Hidden danger, no fire hazard, fast heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

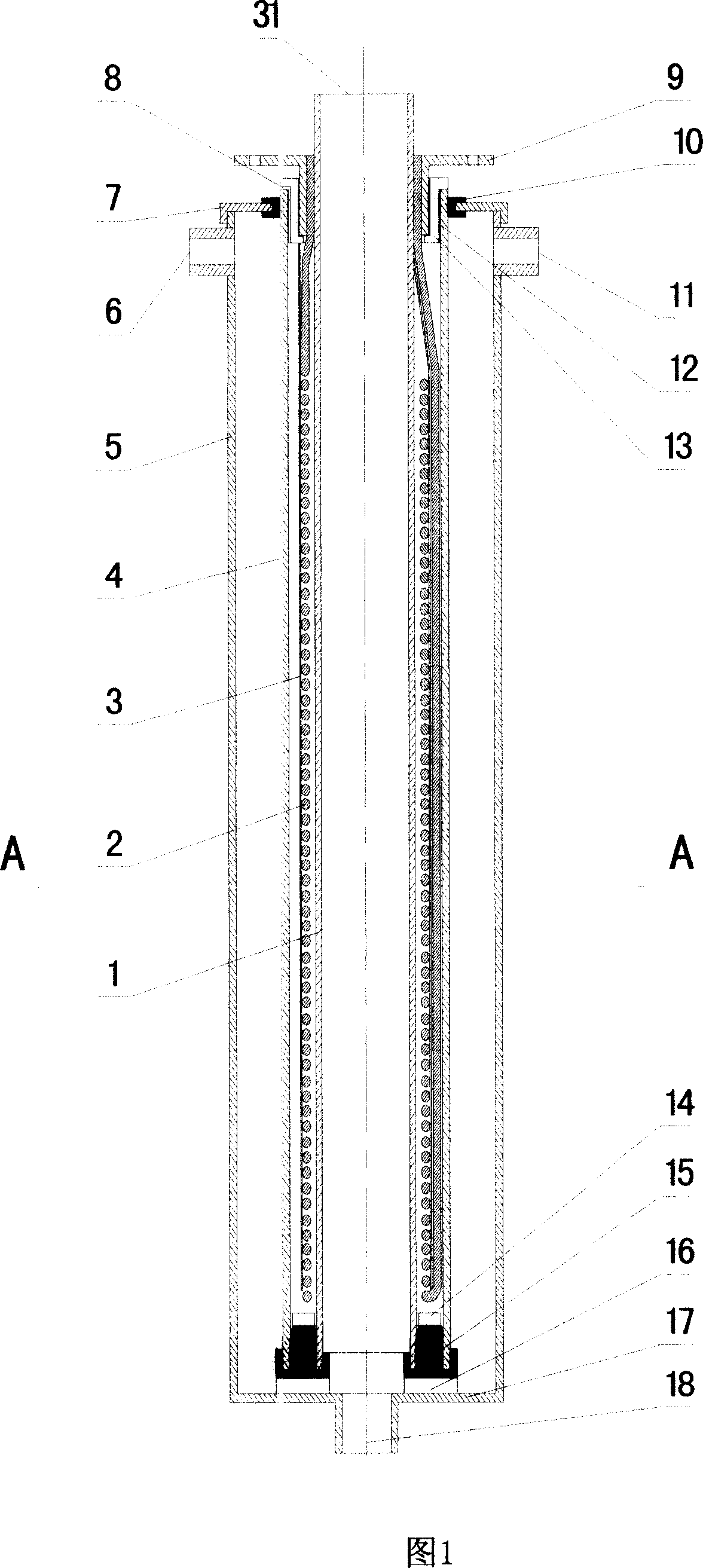

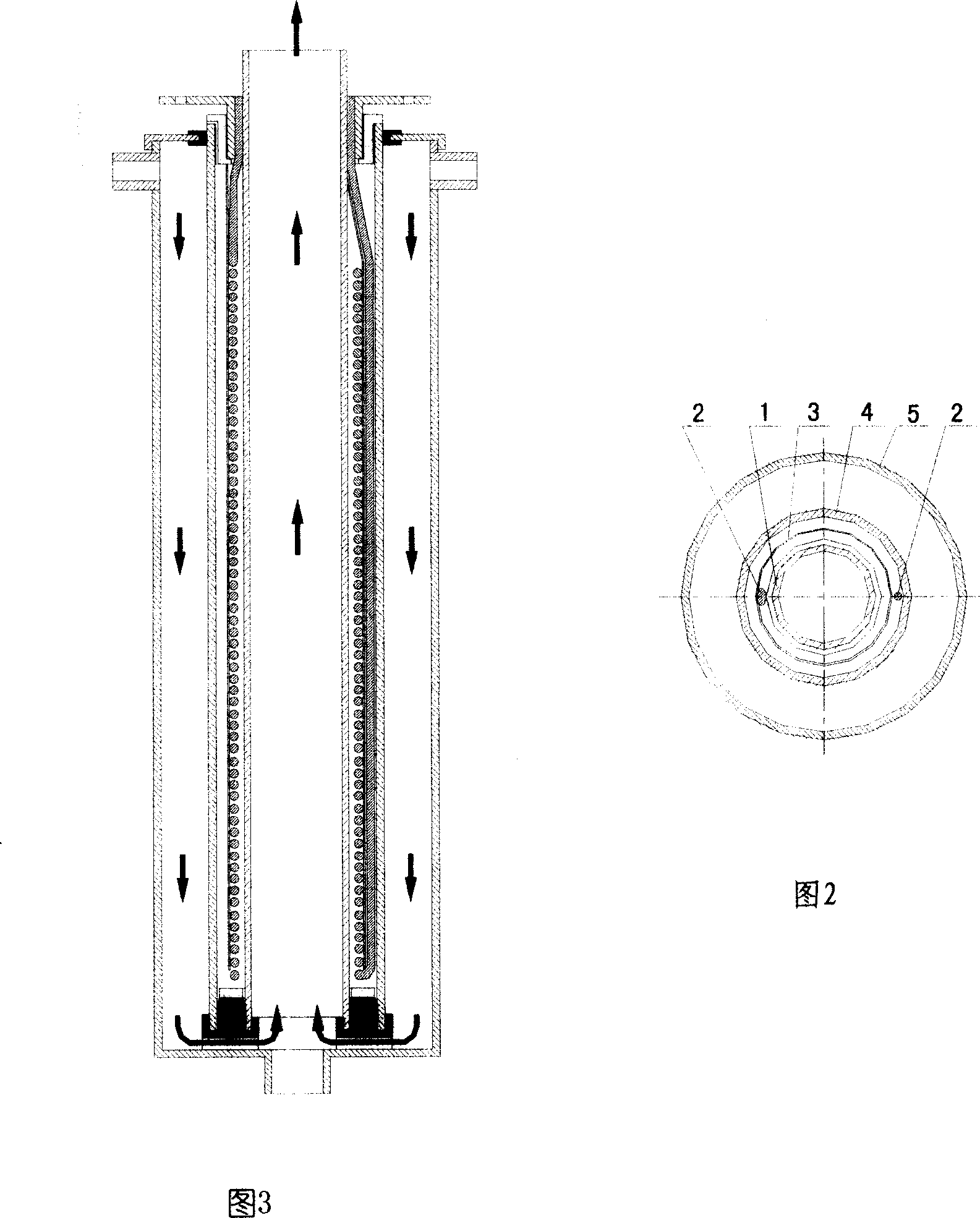

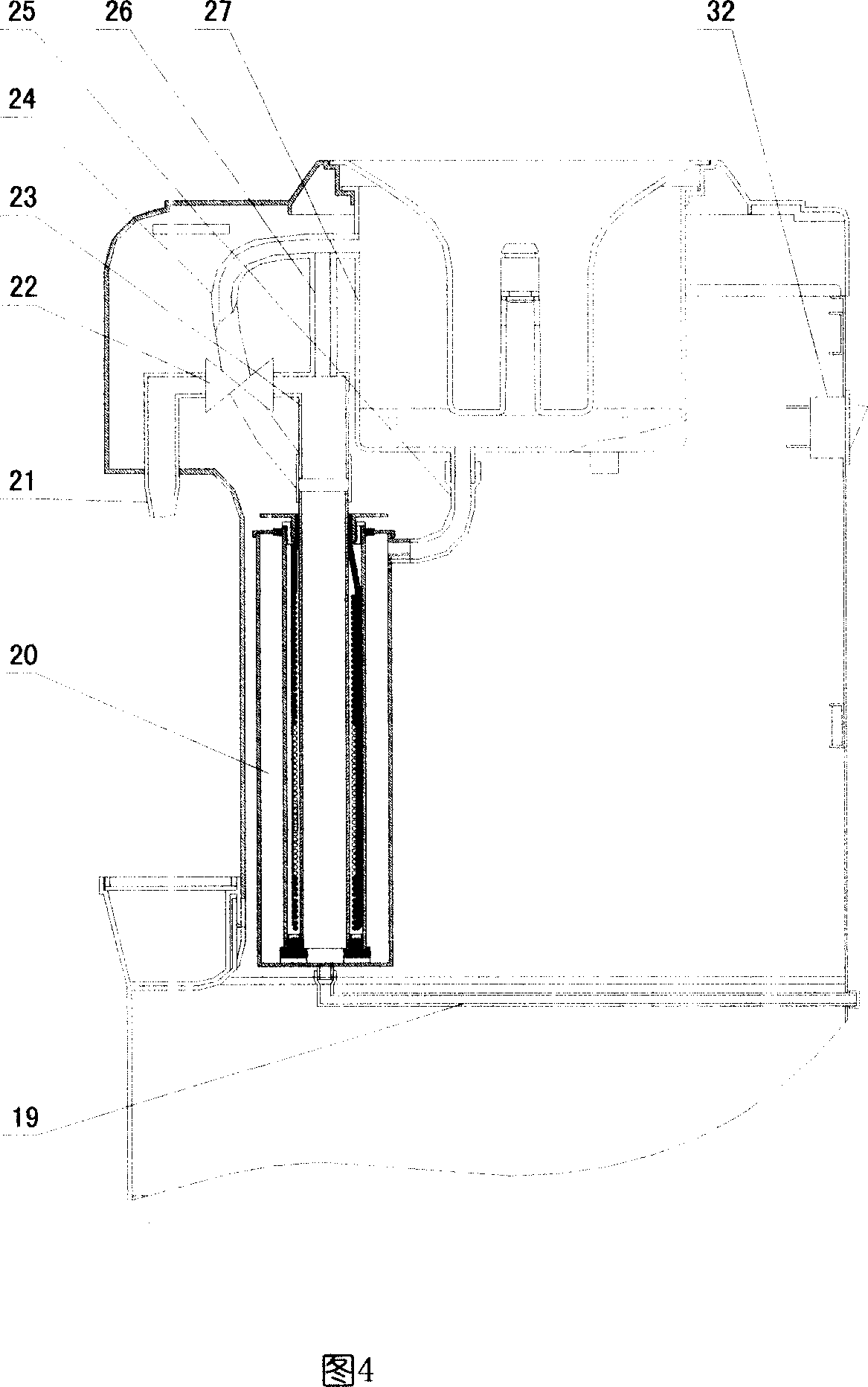

[0017] Embodiment 1: As shown in Fig. 1, Fig. 2 and Fig. 3, a heating wire (2) is arranged on the outside of the high-temperature-resistant glass water pipe (1), and an insulating and heat-insulating layer (3) is arranged on the outside of the heating wire (2). A water jacket composed of an inner cylinder (4) and an outer cylinder (5) is arranged on the outer side of the insulating heat insulation layer (3), and a water inlet (6) and an exhaust port (11) are arranged on the upper part of the water jacket, and the outer cylinder ( 5) The lower end is provided with a head (17), the head (17) is provided with a sewage outlet (18), and the lower end of the water pipe (1) and the lower end of the inner cylinder (4) are provided with a valve to prevent water from entering the cavity where the heating element is located. The sealing ring (15) of the body, the bottom of the sealing ring (15) is provided with a water channel (16), the top of the sealing ring (15) and the bottom of the h...

Embodiment 2

[0021] Shown in conjunction with Fig. 5, present embodiment is a kind of simplification to embodiment 1, and in this embodiment, inner cylinder and water pipe are a composite housing (28) that is connected as one at its lower end, in this housing The lower part is provided with an annular gasket (30), the lower end of the annular gasket (30) is provided with a water channel (32), and a ceramic ring (29) is arranged in the inner cavity of the lower part of the composite casing (28). Due to the presence of the ceramic ring, the distance between the heating wire and the annular pad (30) increases, so when the electric heater in this embodiment is energized and heated, the temperature of the annular pad (30) will not be too high. The ring pad (30) is used to support the composite shell (28) and the water channel (32) thereon is also a channel for water to flow from the water jacket to the water pipe. Other requirements of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com