Vehicular equipment bituminous pitch automatically combined valve device

A technology of automatic combination and on-board equipment, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of vehicle equipment space limitations, manual opening, inconvenient operation, etc., and meet the conditions of compact structure, high degree of standardization, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

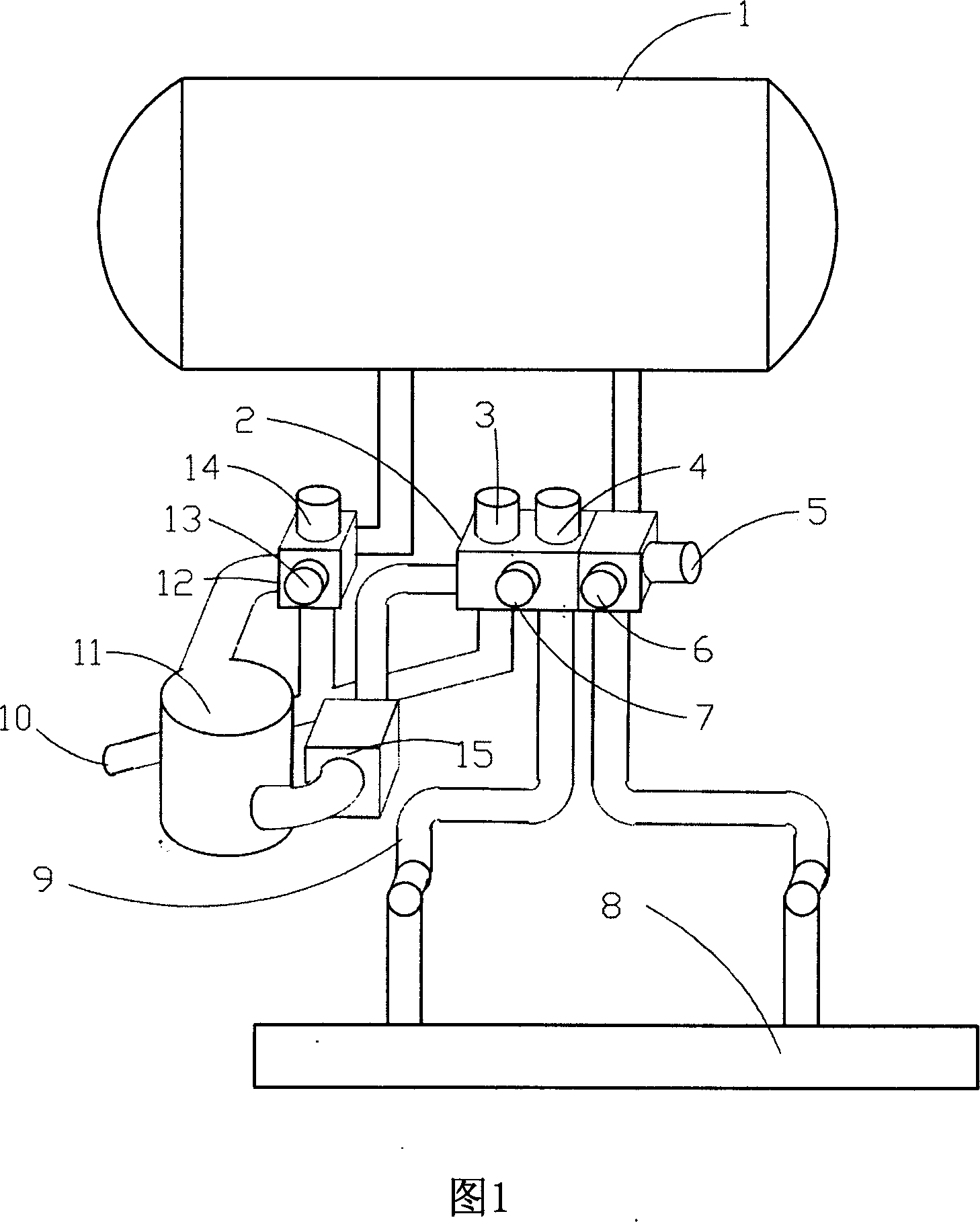

[0021] As shown in the figure, the vehicle-mounted equipment asphalt automatic combination valve device related to the present invention includes a combination valve 12 for asphalt loading out of the tank, a flange interface on the asphalt tank 1, a combination valve 2 for asphalt working conditions, and a connecting pipeline. 9. Spraying arm 8, asphalt tank 1, asphalt filter 11 and asphalt pump 15, the asphalt loading out tank combination valve 12 is composed of asphalt out tank valve 13 and asphalt loading valve 14, and the asphalt working condition combination valve 2 is composed of The asphalt small circulation return tank valve 7, the asphalt delivery valve 4, the asphalt large circulation return tank valve 6, the asphalt emptying valve 3 and the bypass valve 5 constitute.

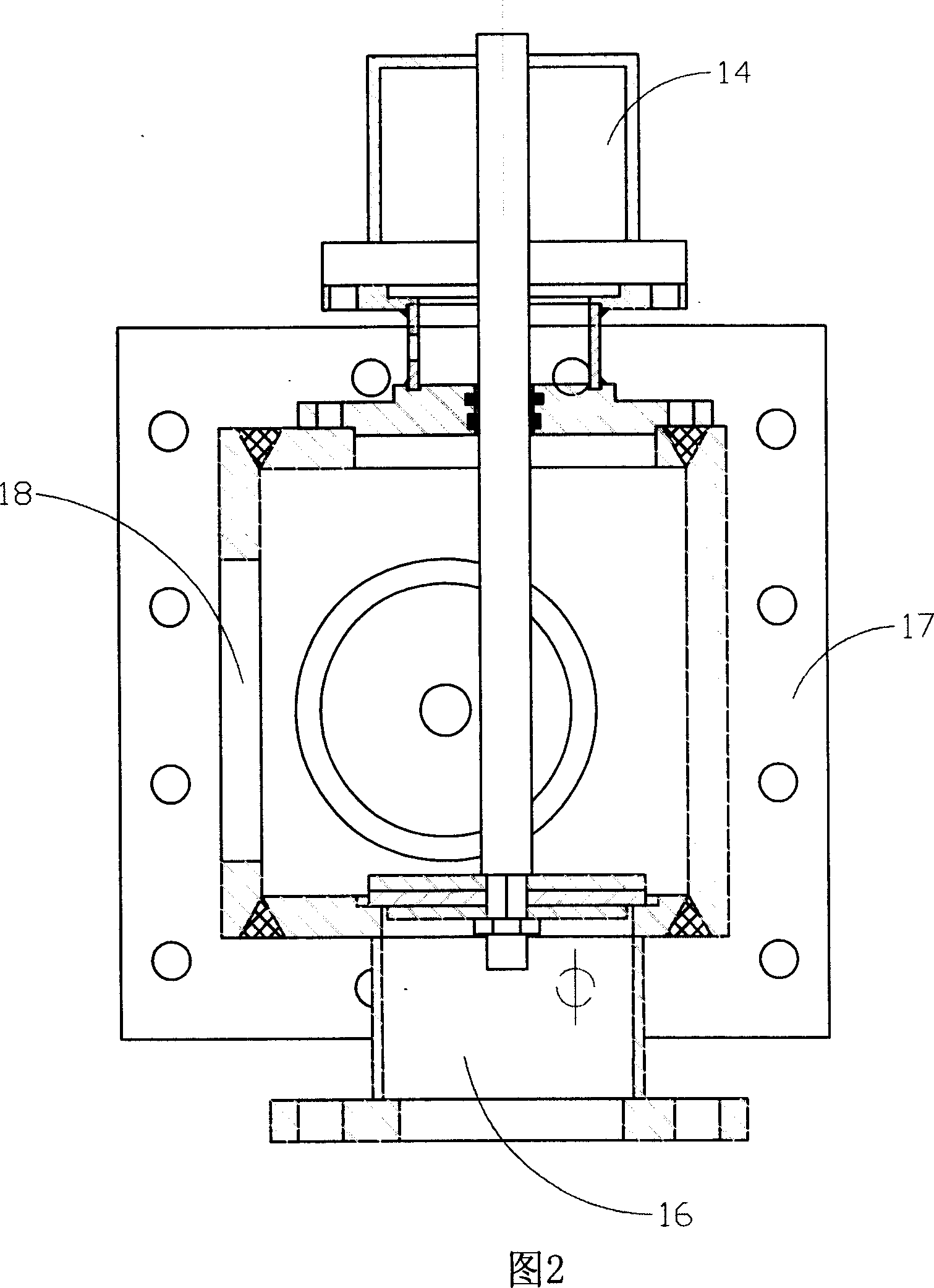

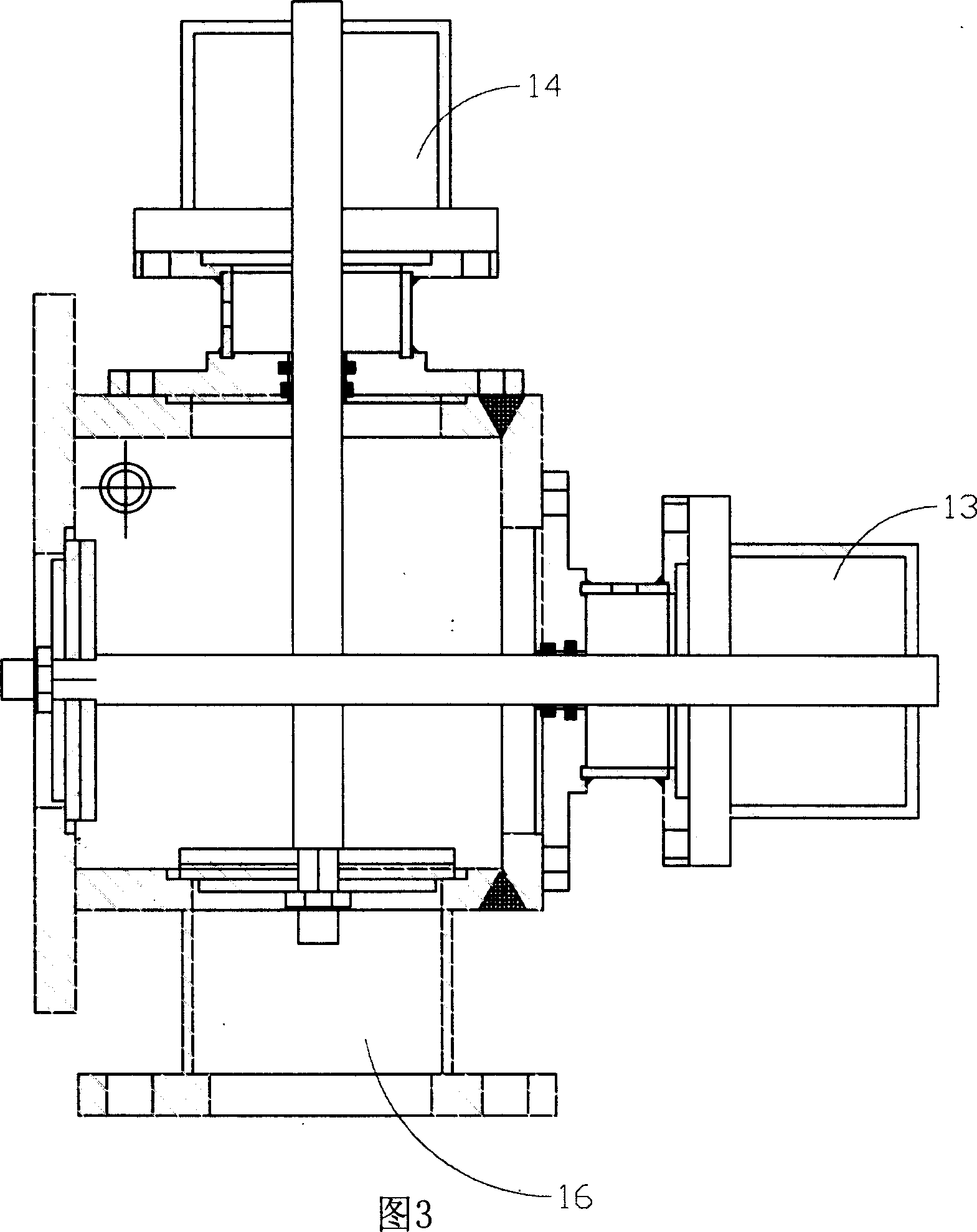

[0022] The external suction port 16 of the asphalt loading valve 14 on the asphalt loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com