Floating type ship unloading equipment

A floating and equipment technology, applied in the direction of loading/unloading, trolley cranes, cranes, etc., can solve the problems of poor environmental adaptability, environmental pollution, high energy consumption, etc., and achieve high operating efficiency, good adaptability, and high operating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] The relevant data of this embodiment is based on the existing equipment, ships to be unloaded and production

[0027] The relevant data of this embodiment are obtained through modeling analysis, screening and comparison according to the existing equipment, ships to be unloaded and production rate requirements of WISCO Industrial Port.

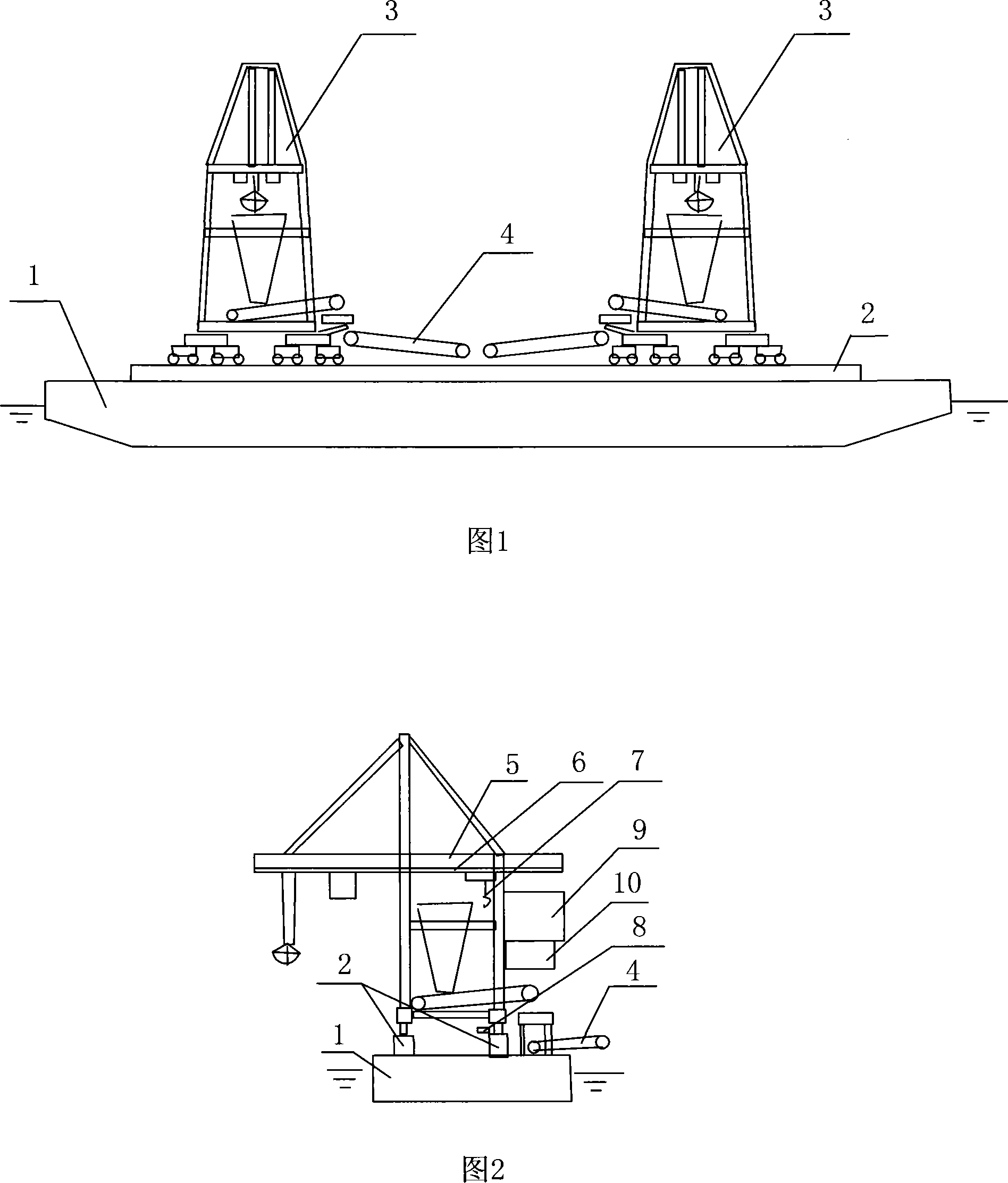

[0028] figure 1 , figure 2 The shown floating ship unloading equipment combines barge 1, track 2, bridge type grab ship unloader 3 and belt transmission device 4 to form an integrated floating ship unloading equipment. Among them, two rails 2 are installed longitudinally on the barge deck, the rail gauge is 14 meters, and the base distance is 12 meters. The bridge type grab ship unloader 3 is set on the rails 2. figure 1 , there are two bridge-type grab ship unloaders in this embodiment, and the two bridge-type grab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com