Container conversion device for semi-conductor packaging element

A conversion device, semiconductor technology, applied in furnace components, conveyor objects, transportation and packaging, etc., can solve the problems of easy bumping of semiconductor components, large labor demand, slow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention are described in detail as follows, however, the present invention can be widely implemented in other embodiments besides the detailed description. That is to say, the scope of the present invention is not limited by the proposed embodiments, but should be based on the patent scope of the present invention.

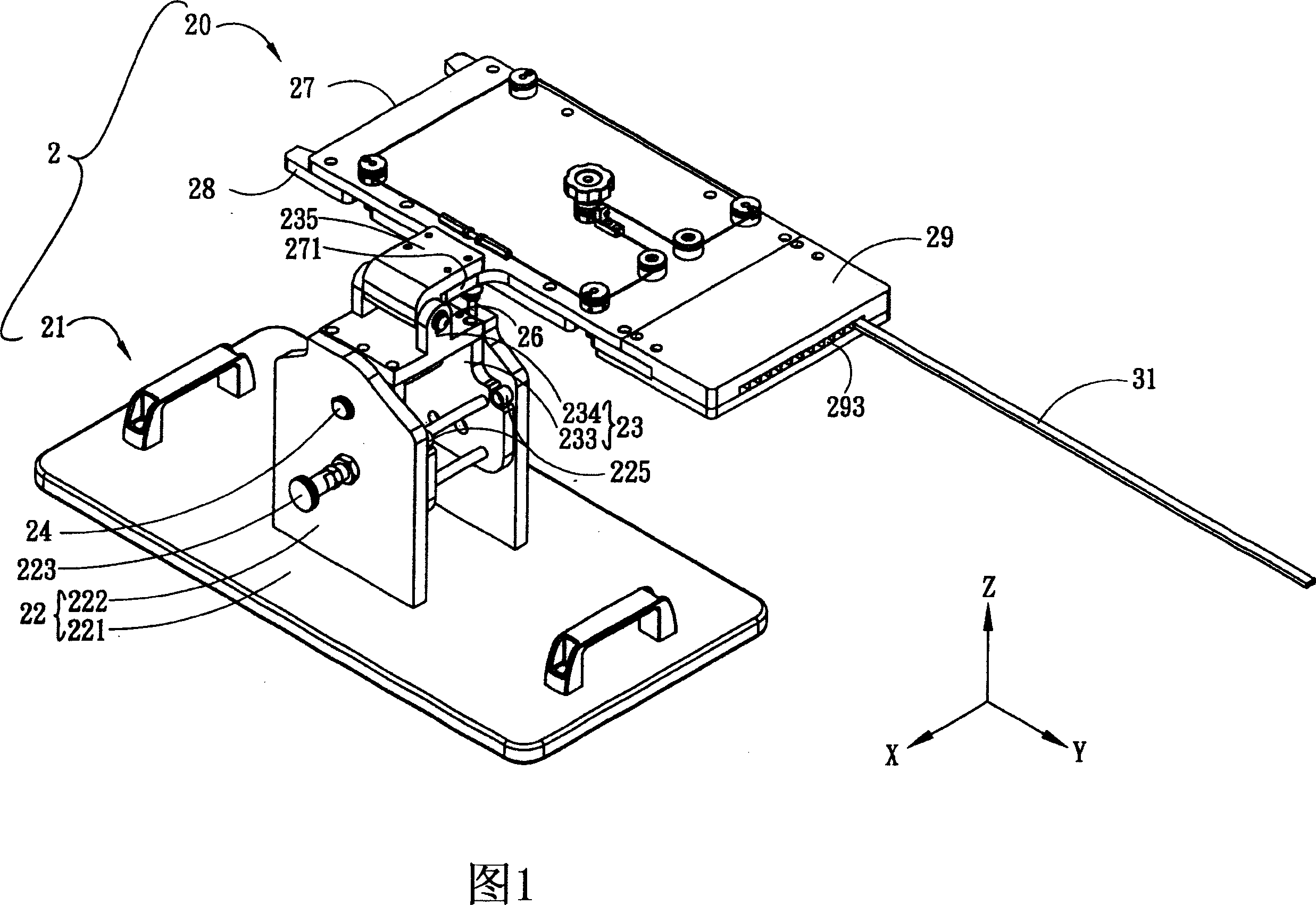

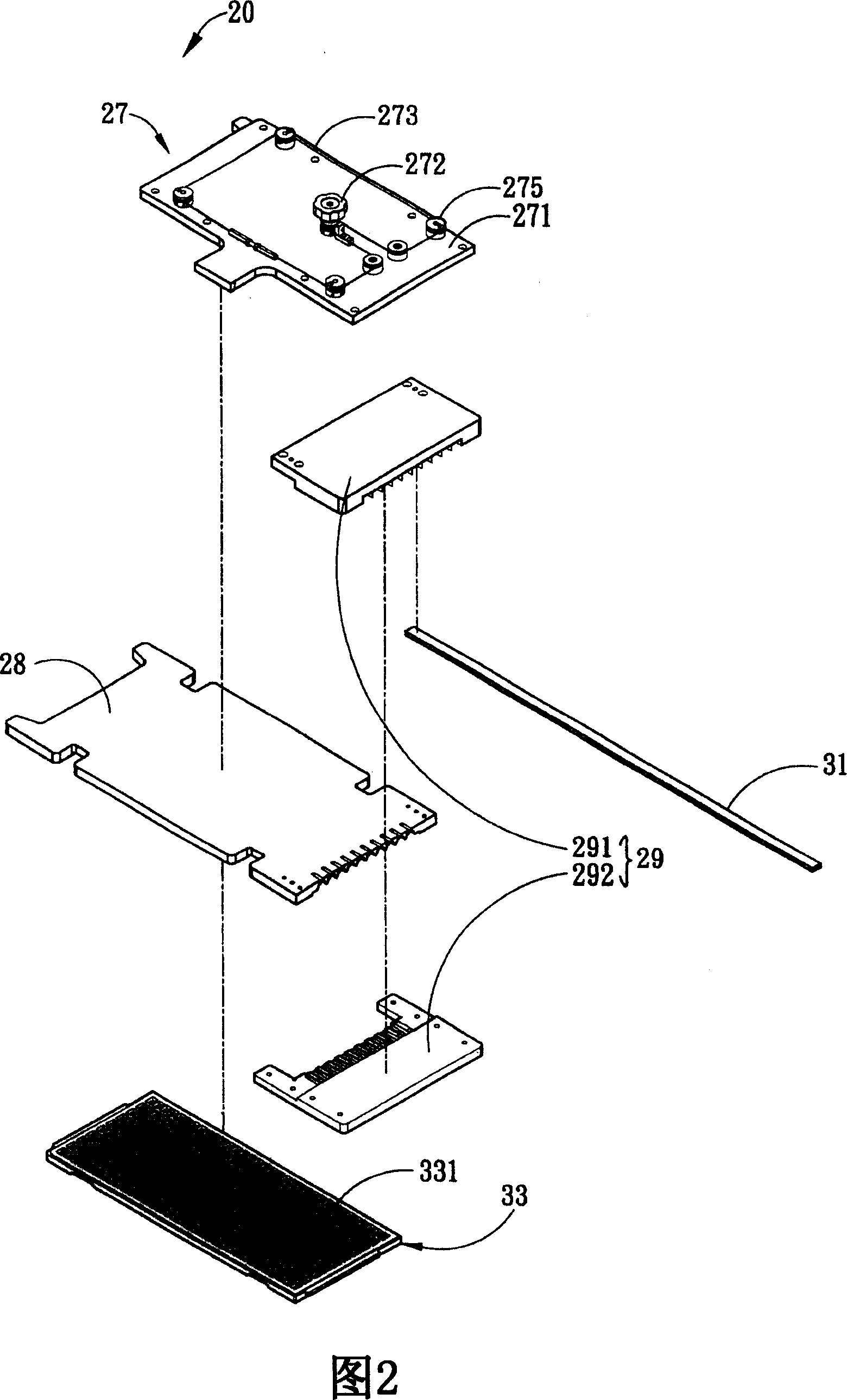

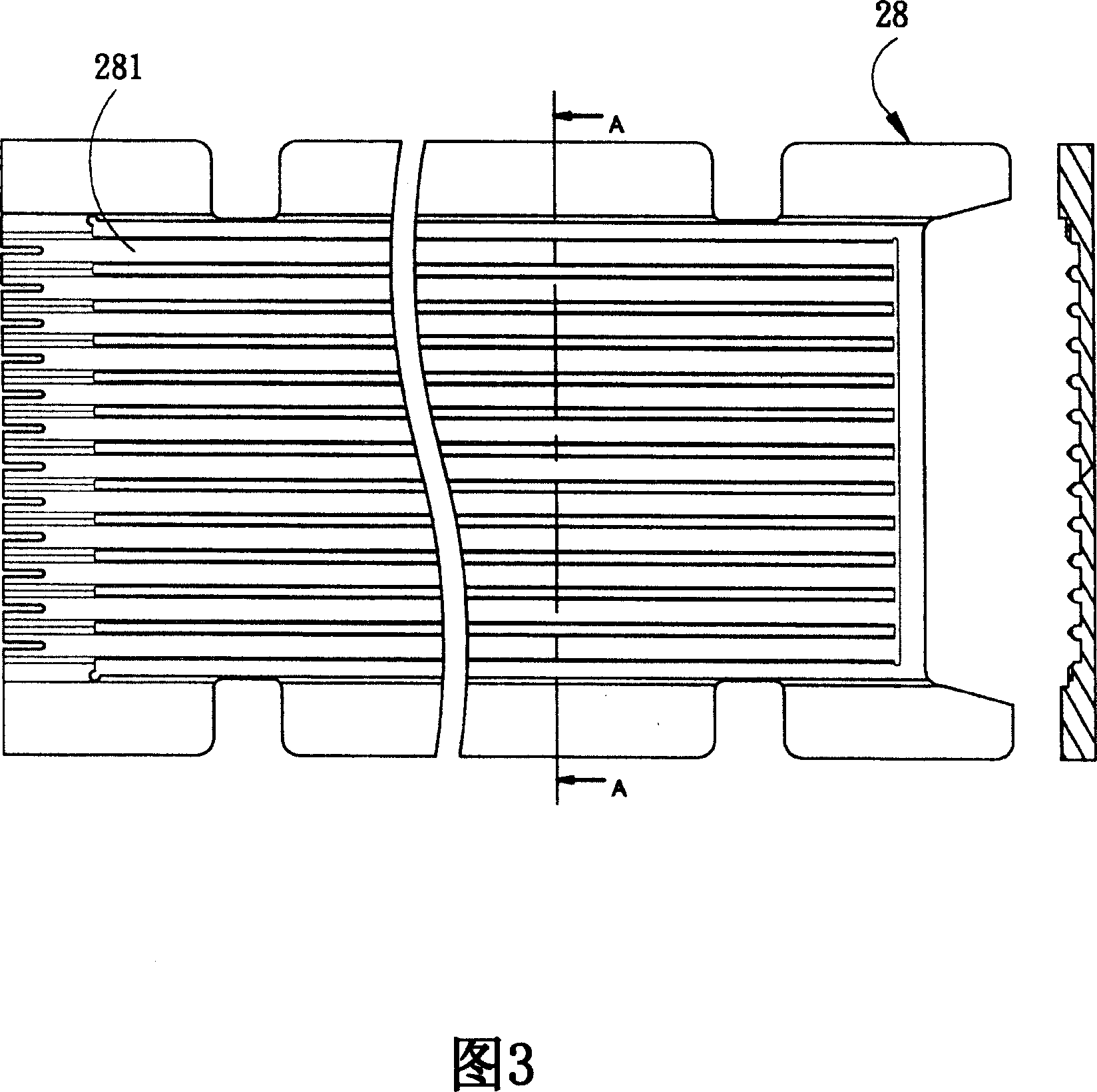

[0050] The perspective view of FIG. 1 shows a container conversion device 2 for semiconductor packaging components according to an embodiment of the present invention, which mainly includes a pallet clamping mechanism module 20 and a biaxial rotating mechanism module 21 . Wherein, the exploded view of the constituent elements of the clamping tray mechanism module 20 is shown in FIG. There are a plurality of accommodating grooves 331 respectively used for accommodating a semiconductor component (not shown in the drawing). The tray clamping mechanism module 20 mainly includes a slideway base plate 28 , a tray clamp 27 and an intu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com