Lifting device and controlling method thereof

A control method and tally technology, applied in storage devices, electrical program control, program control in sequence/logic controllers, etc., can solve interference, cannot correctly predict the timing of the sliding fork, and it is difficult to predict the internal state of the tally device and other problems, to achieve the effect of small rigidity, shortened tally time, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Preferred examples for carrying out the present invention are shown below.

[0048] (Example)

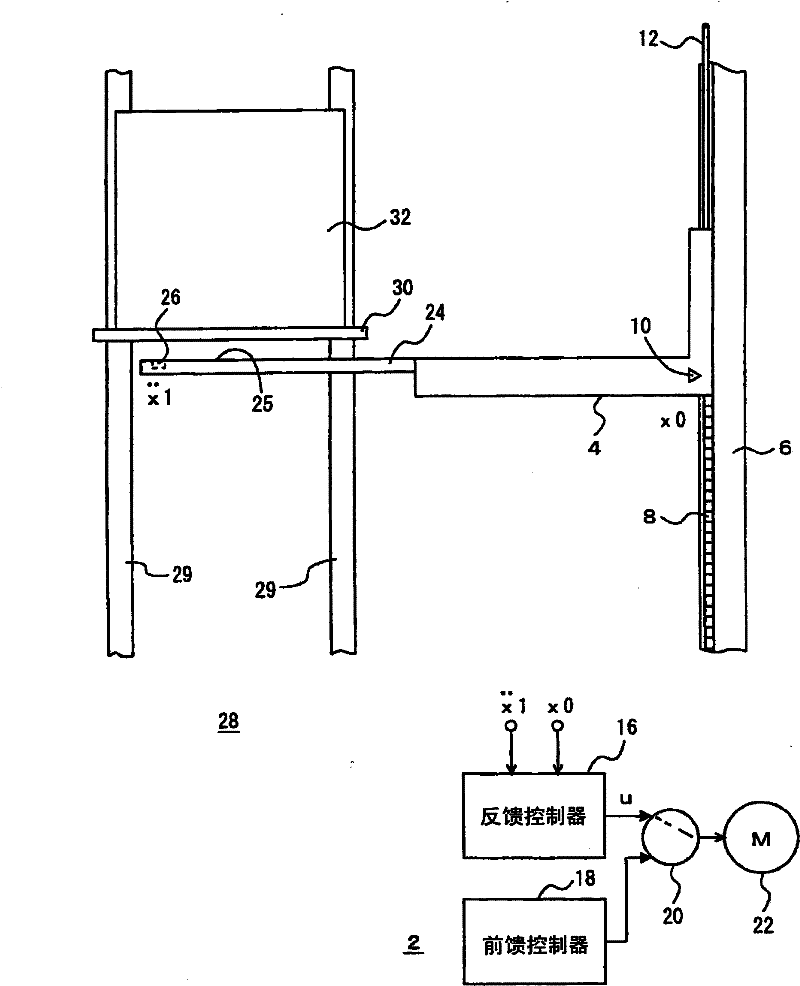

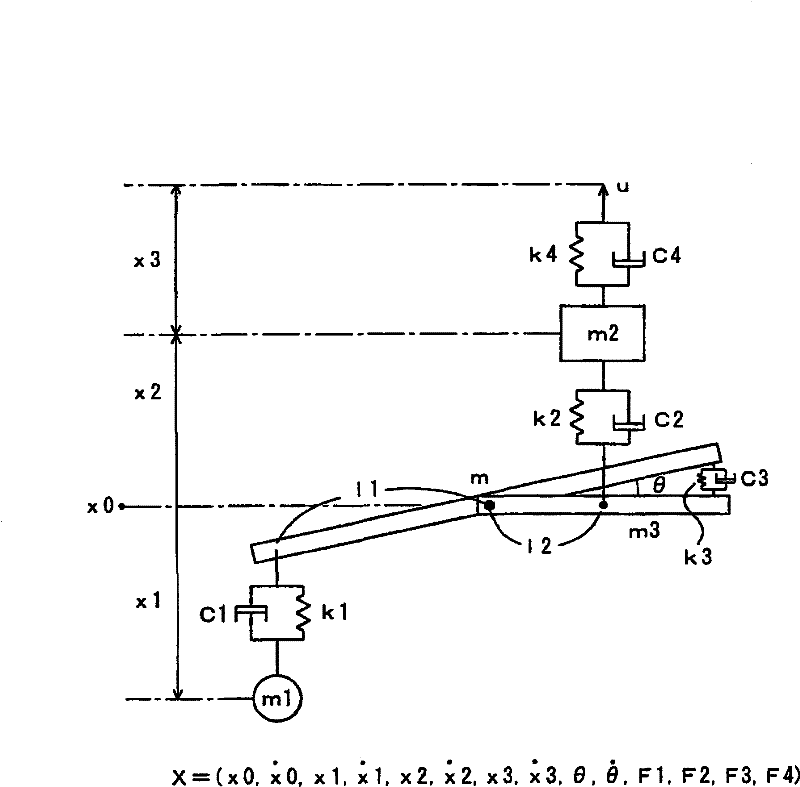

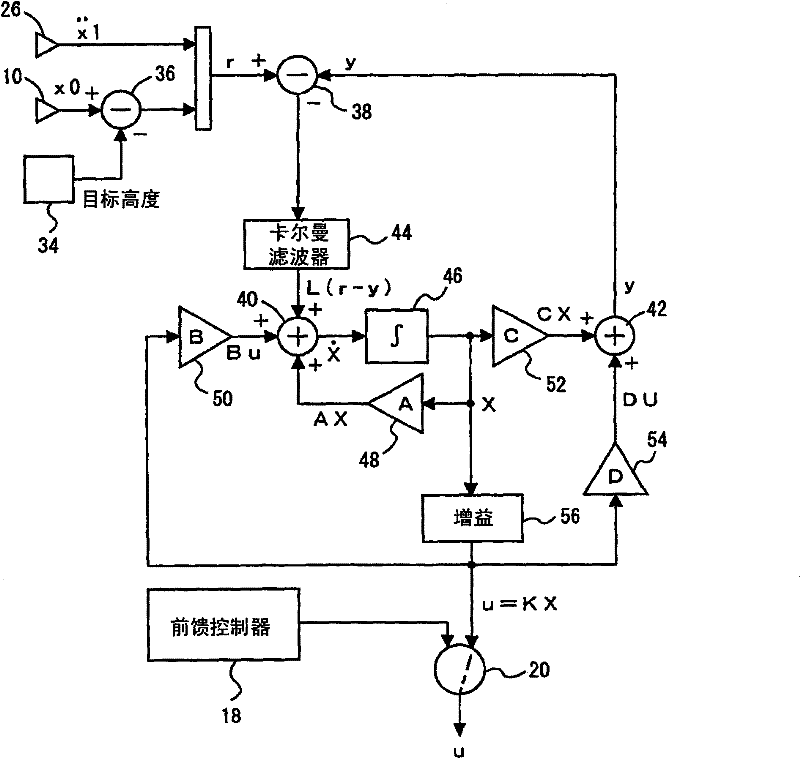

[0049] exist Figure 1 to Figure 9 In , the embodiment and its characteristics are shown by taking the control of the lifting table 4 in the stacking crane 2 as an example. In each figure, the lifting table 4 is guided by the column 6 to lift, and a linear scale 8 is arranged on the column 6 along the height direction, and the height position x0 of the lifting table 4 is read by the linear sensor 10 arranged on the lifting table 4 . Furthermore, the elevating platform 4 is suspended by a suspending member 12 such as a timing belt, a wire, or a rope, and is raised and lowered by an elevating motor 22 together with a counterweight (not shown). The lifting motor 22 is controlled by a feedback controller 16 and a feedforward controller 18 , and a switch 20 is used to switch to use a certain controller. switch is via Figure 4 In the speed graph of the solid line in , the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com