Mechanical plane

A motorized and main part technology, applied in the field of manual motorized planers, can solve the problems of not being able to maintain the specified depth of planing, reducing the initial diameter, and reducing the service life of the motorized planer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

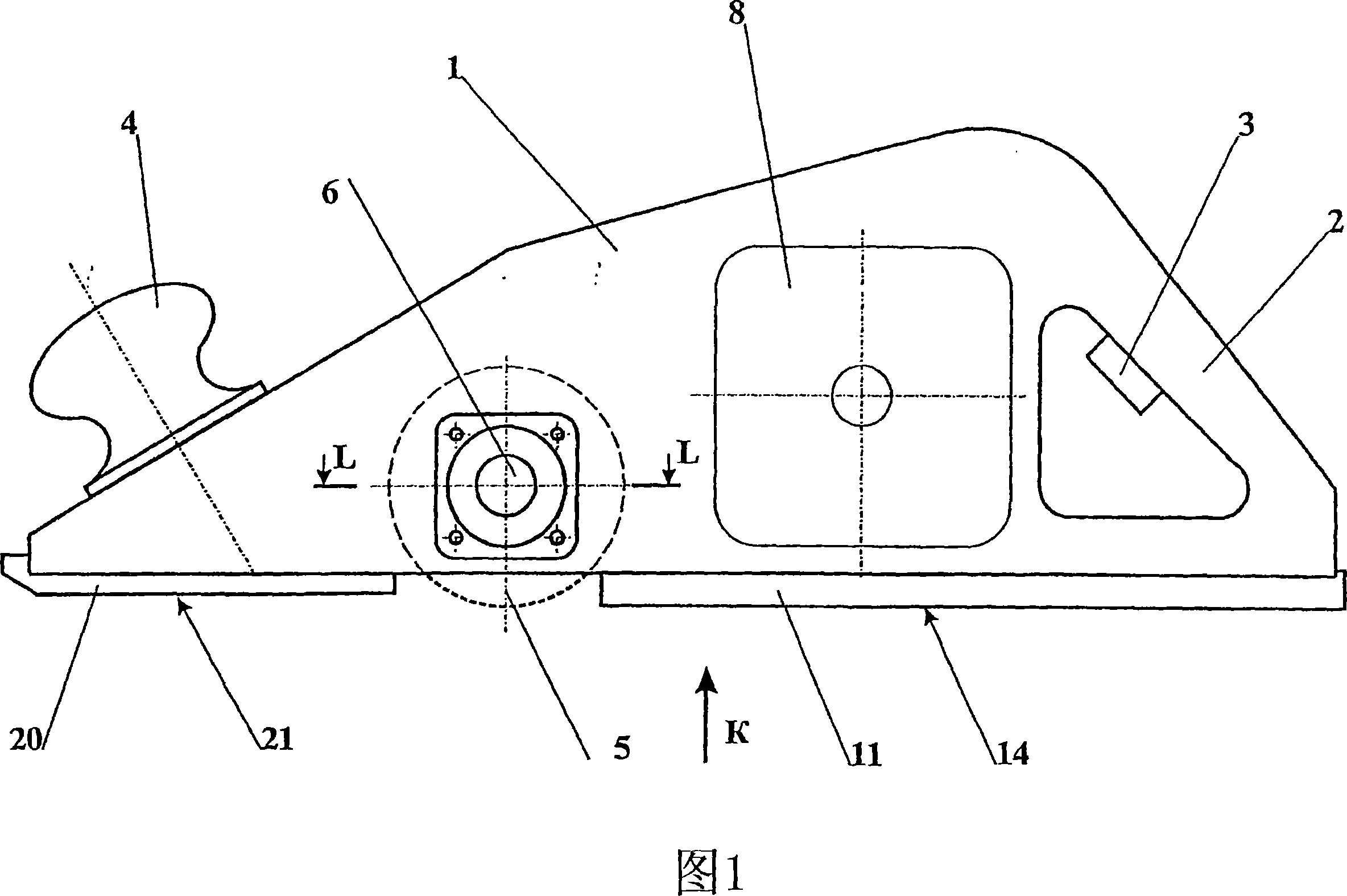

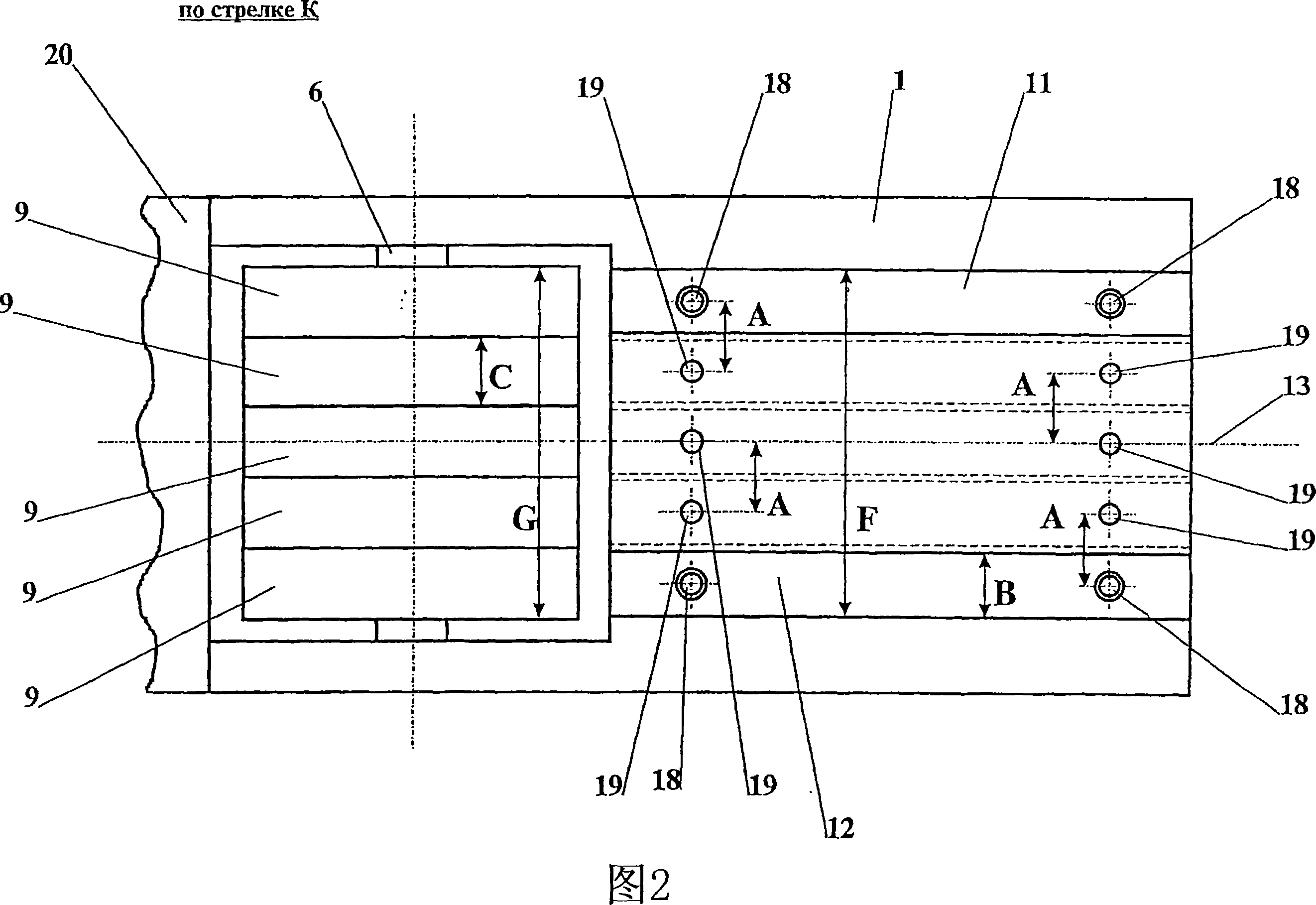

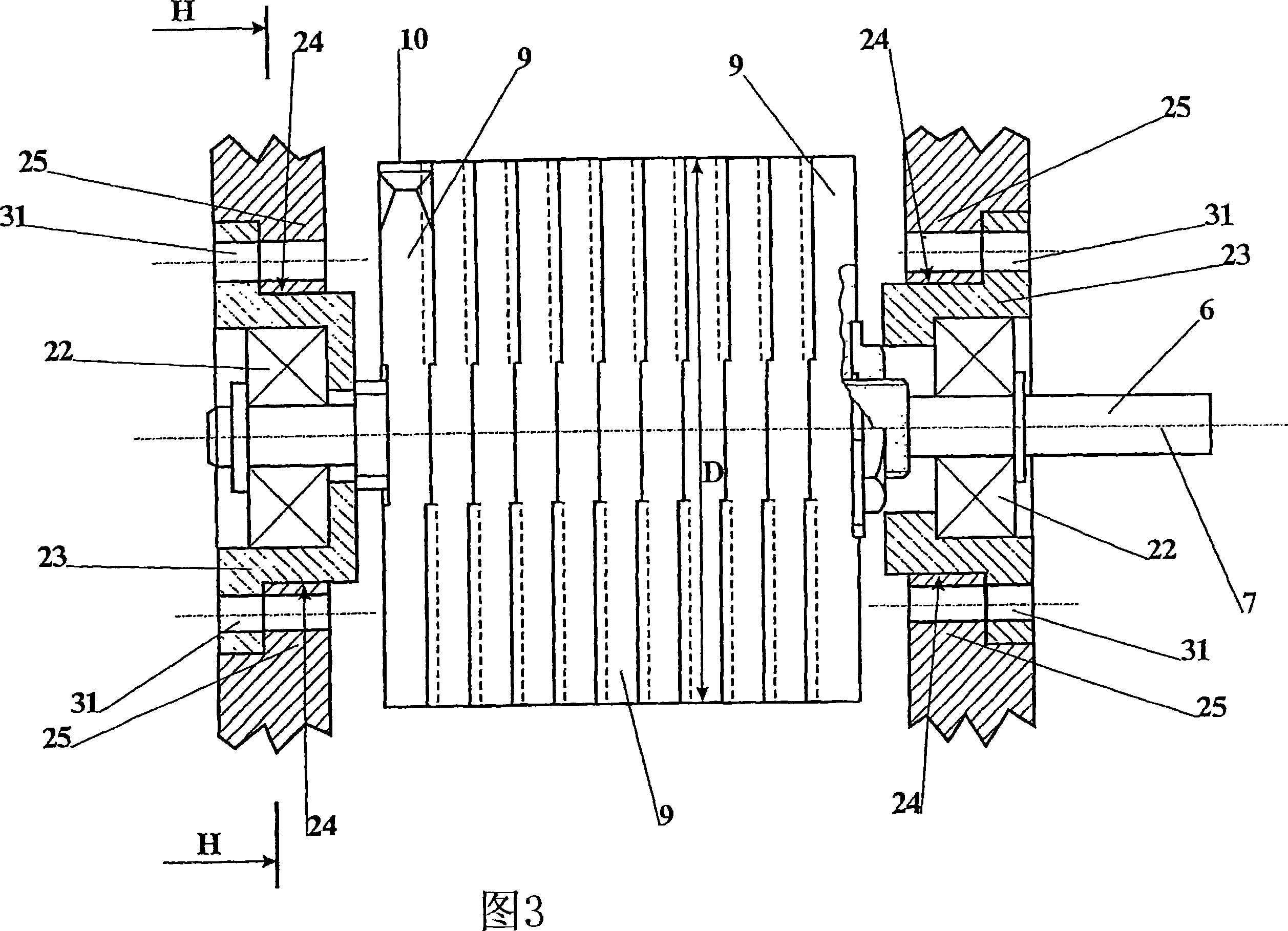

[0023] The motor planer comprises a main body part 1 with a rear handle 2 housing an actuating mechanism (not shown) via a trigger 3 , and a front handle 4 . The body part 1 has an area accommodating a cutting head 5 driven by a drive shaft 6 with freedom of rotation about a longitudinally extending axis of symmetry 7 and firmly fastened to the drive shaft 6 by some means. The means for clamping the cutting head 5 on the drive shaft 6 may be provided as any known releasable connection, such as a barbed or keyed joint. The drive shaft 6 is kinematically connected to a motor 8 which is placed in the inner region of the body part 1 . The motor 8 used can be represented by any known motor, such as an electric motor or a compressed air motor. The kinematic connection between the motor 8 and the drive shaft 6 may for example be in the form of a belt drive (not shown). The cutting head 5 ( FIG. 3 ) is in the form of at least two faceted cutters 9 mounted on a drive shaft 6 . Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com