Semiconductor element with U shaped drift region

一种半导体、漂移区的技术,应用在半导体器件、电固体器件、电气元件等方向,能够解决成本提高、工艺复杂性等问题,达到电流关断时间缩短、工艺简单、降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

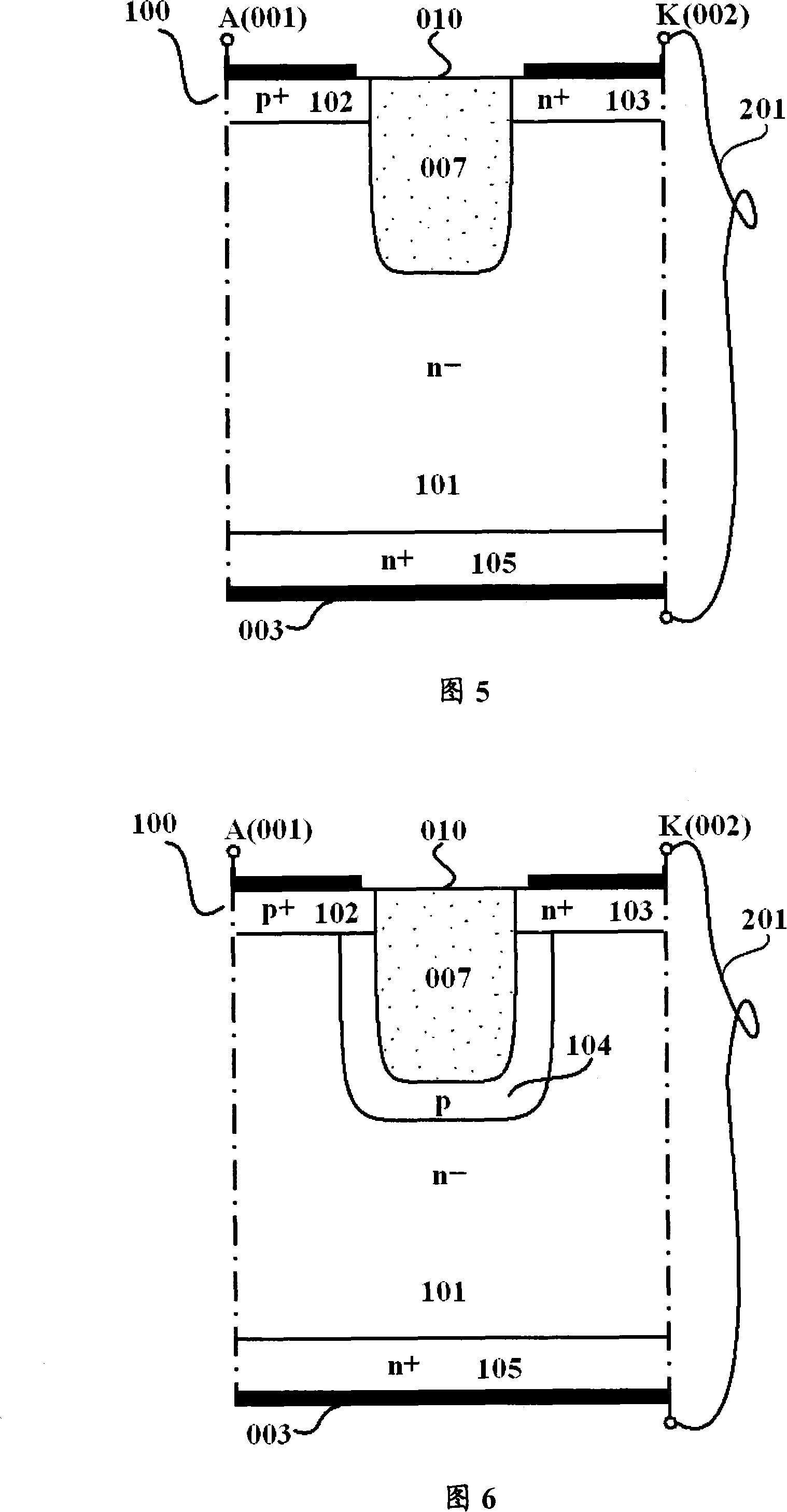

[0060] The withstand voltage situation of the drift region of the present invention is firstly explained with a p-n diode, because actually the withstand voltage situation of the drift region of various devices can be regarded as the situation of a p-n junction under reverse bias voltage. FIG. 5 shows a schematic cross-sectional view of the structure of a unit 100 of a device proposed by the present invention. Dotted lines in the figure indicate boundaries between one cell and another. n in the figure - Area 101 is a drift area, which is in the shape of a "U". Between the two sides of the "U" is a slot 010 filled with an insulator 007, represented by a region with many dots in the figure. The parts of the semiconductor on both sides of the trench that are close to the first main surface are the characteristic regions of the two devices, the first characteristic region is on the first side, the second characteristic region is on the second side, and the two sides of the "U" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com