Waste and old se-drum reclaiming and processing technique

A technology for recycling and processing toner cartridges, which is applied in the field of industrial solid waste control and resource utilization, and can solve problems such as low efficiency of manual dismantling, secondary pollution, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

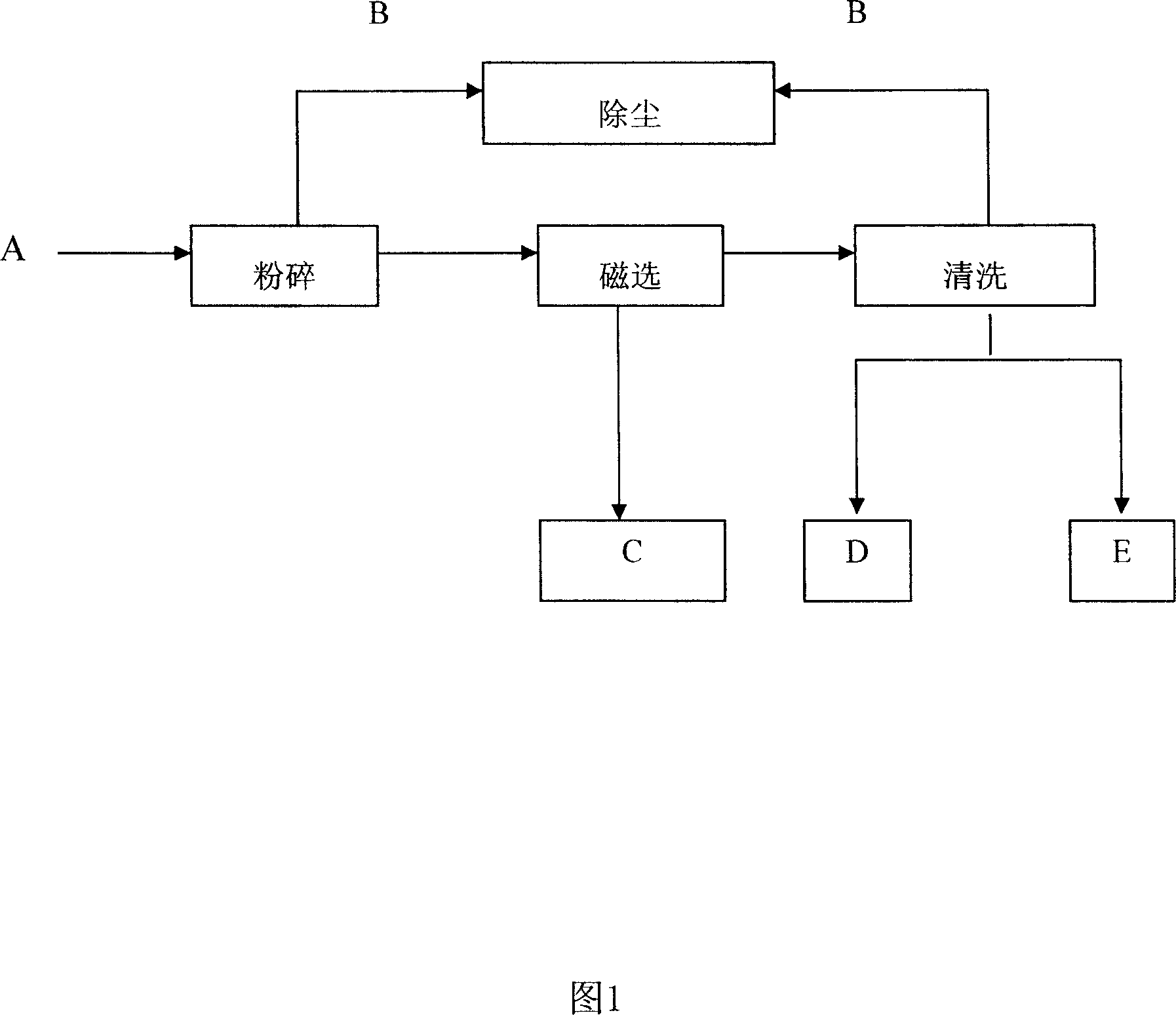

[0017] As shown in Figure 1, in a waste toner cartridge treatment process provided by a preferred embodiment of the present invention, the waste toner cartridge A first enters the hammer mill through a conveyor belt for crushing, and the organic toner B produced during the crushing process is sent to The tuyere is collected by the pulse back-blowing bag filter, and the pulverized materials pass through the magnetic pulley to separate the iron block C through magnetic separation, and the remaining materials pass through the air cleaning machine to separate the remaining organic ink B and other highly adhering substances. Collected by the pulse blowback bag filter through the air supply port, the remaining materials are manually decomposed, and finally plastic D and copper E are obtained to realize the regeneration of resources. By adopting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com