Method for predicting turbine generator insulating thermal aging life

A turbine generator and life prediction technology, which is applied in the direction of engine testing, machine/structural component testing, electrical measurement, etc., can solve problems such as lack of methods and systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

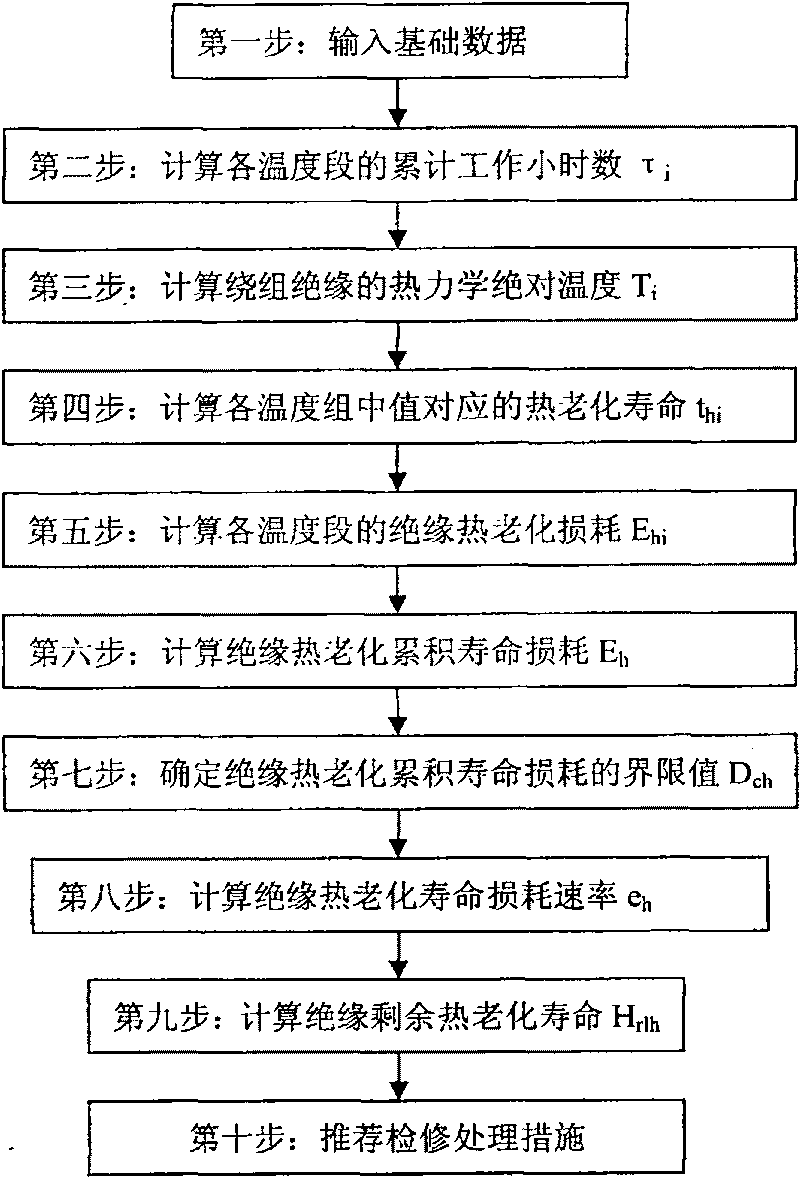

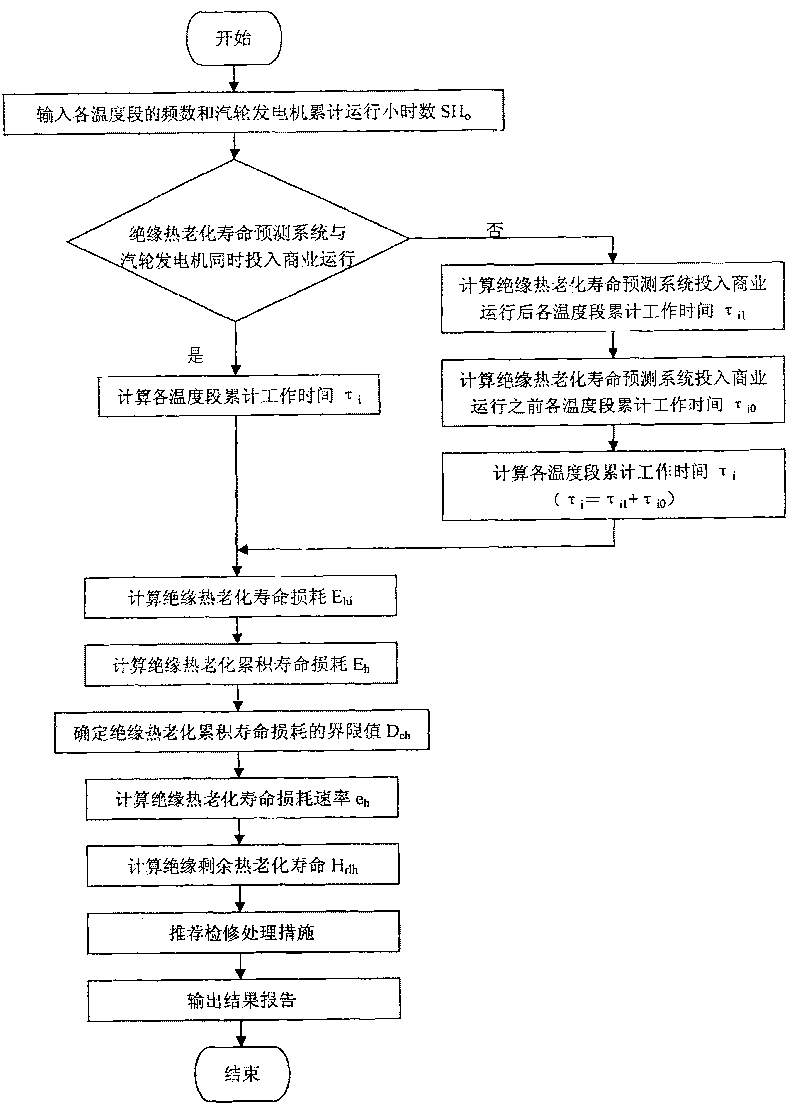

[0068] There are 42 slots in the stator winding of a certain type of 600MW turbo-generator. figure 1 The shown steam turbine generator stator winding insulation thermal aging life online prediction system adopts figure 2 The flow chart of the online prediction method for the thermal aging life of the stator winding insulation of the turbo generator shown and image 3 The computer software for the online prediction of the thermal aging life of the stator winding insulation of the steam turbine generator shown is running on the calculation / application server of the power plant control center. For the 42 stator slot windings of this type of turbo-generator, during the grid-connected operation of the unit, the database saves stator winding temperature data every 30 minutes. Above 41℃ (41℃ to 90℃) every 5℃ is regarded as a temperature section. Below 40℃ is regarded as a temperature section, and the actual temperature monitored above 91℃ is stored in the database. The thermal aging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com