Multi-layer wood composite flooring and manufacturing method therefor

A solid wood composite floor and veneer technology, which is applied in building structures, floors, buildings, etc., can solve the problems of easy moisture expansion, easy scratching, poor waterproofness, etc., and achieves high surface strength, not easy to deform, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

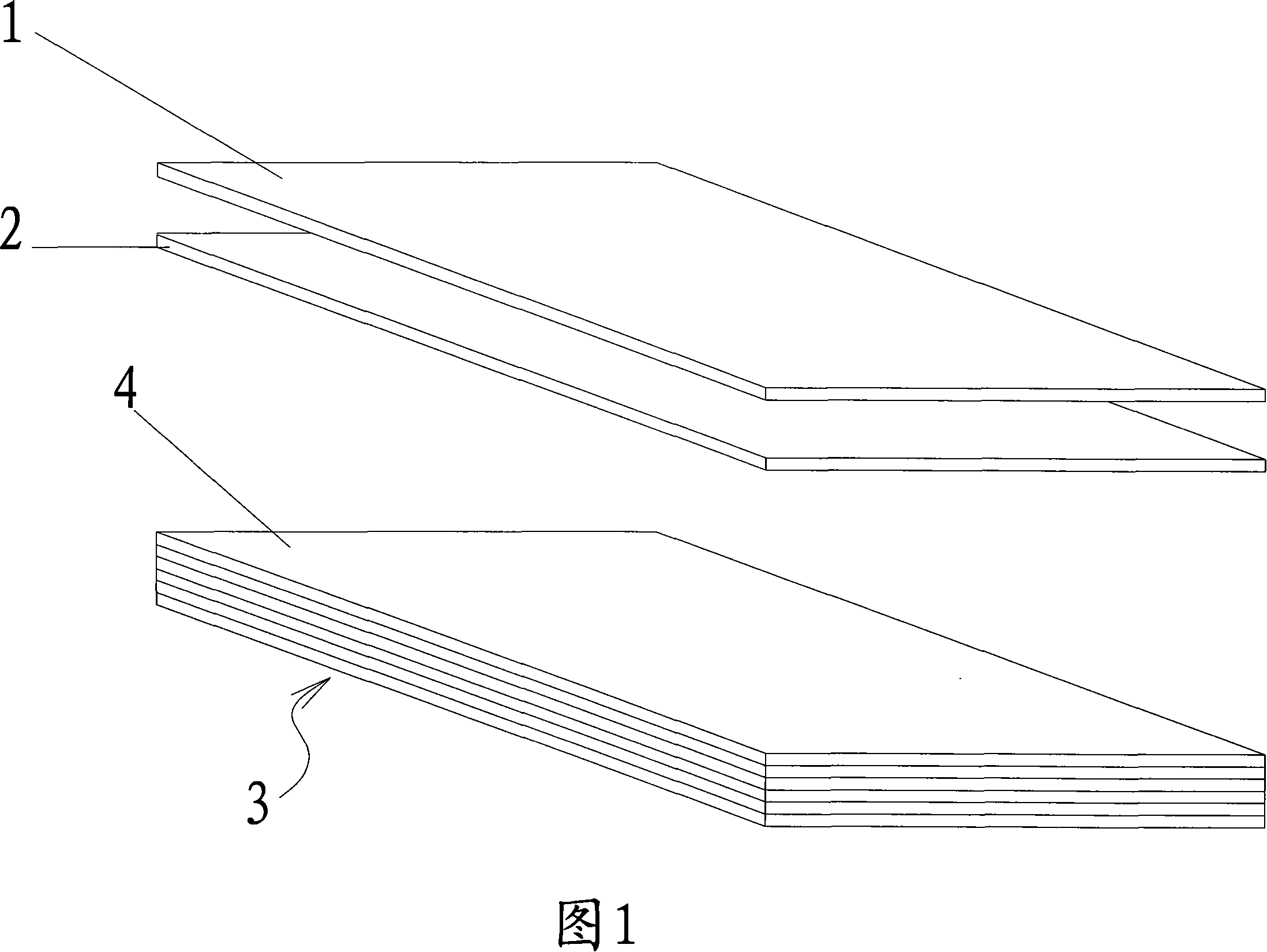

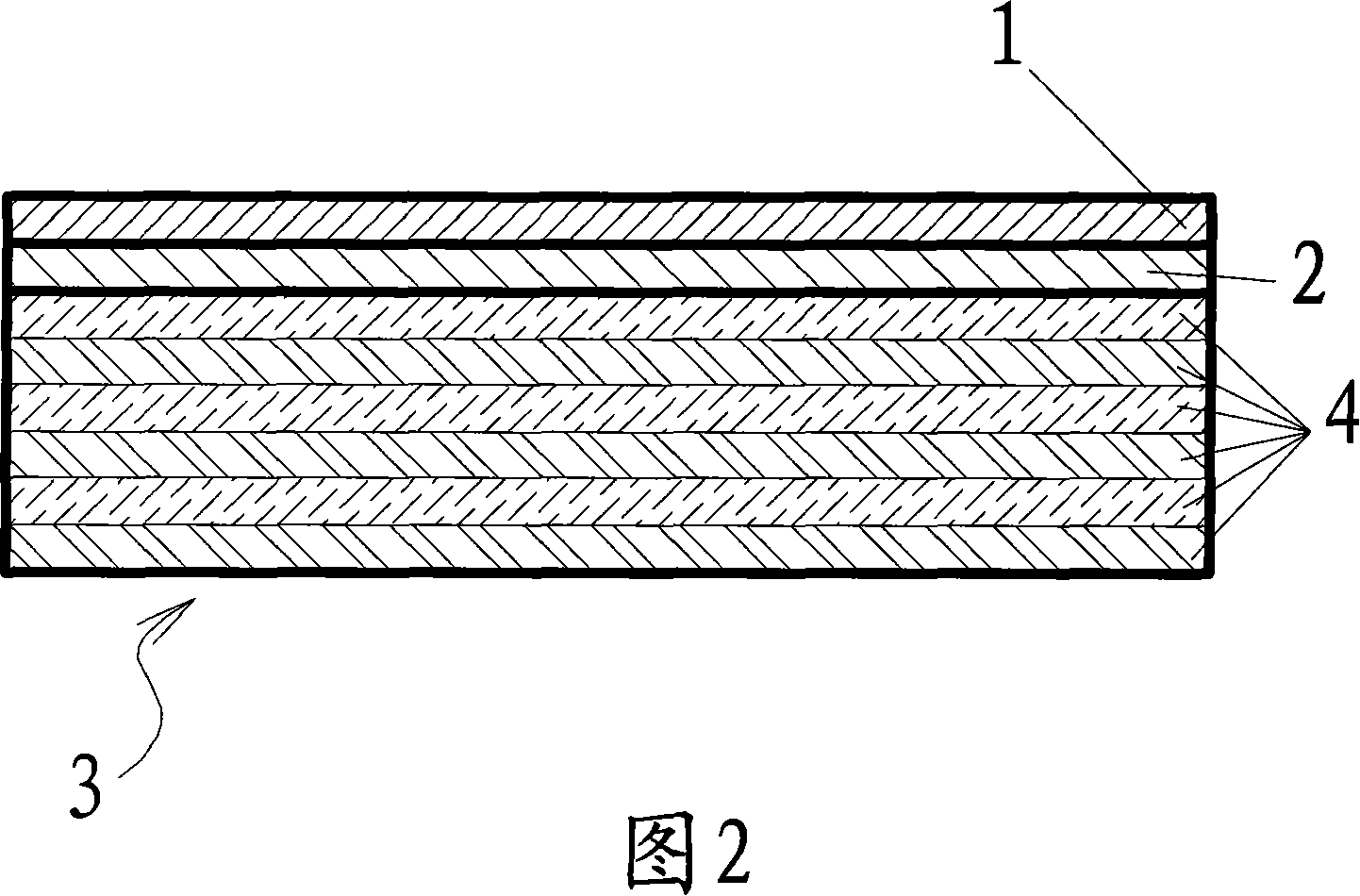

[0028] With reference to Fig. 1, Fig. 2, a kind of multi-layer solid wood composite floor, comprises wear-resisting layer 1, decoration layer 2 and substrate layer 3 that are mutually glued from top to bottom, and described wear-resisting layer 1 is two aluminum oxide wear-resistant Paper, the decorative layer 2 is the veneer obtained by selecting high-quality wood through planing, avoiding the waste caused by sawing gaps in the process of cutting the wood by sawing, and can effectively save precious high-quality wood; in addition, the wear-resistant layer 1 The use improves the surface strength of the floor, making the floor wear-resistant, scratch-resistant, impact-resistant, burn-resistant, pollution-resistant, environmentally friendly, and economical, affordable and durable. The substrate layer 3 includes multi-layer veneers 4 with a thickness of 1 mm-1.5 mm glued to each other. The wood grain directions of two adjacent layers in the multi-layer veneer 4 are criss-crossed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com