Method for coupling and manufacturing ricinus oil biological diesel oil

A technology of biodiesel and castor oil, which is used in the preparation of liquid hydrocarbon mixtures, biofuels, biomaterials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

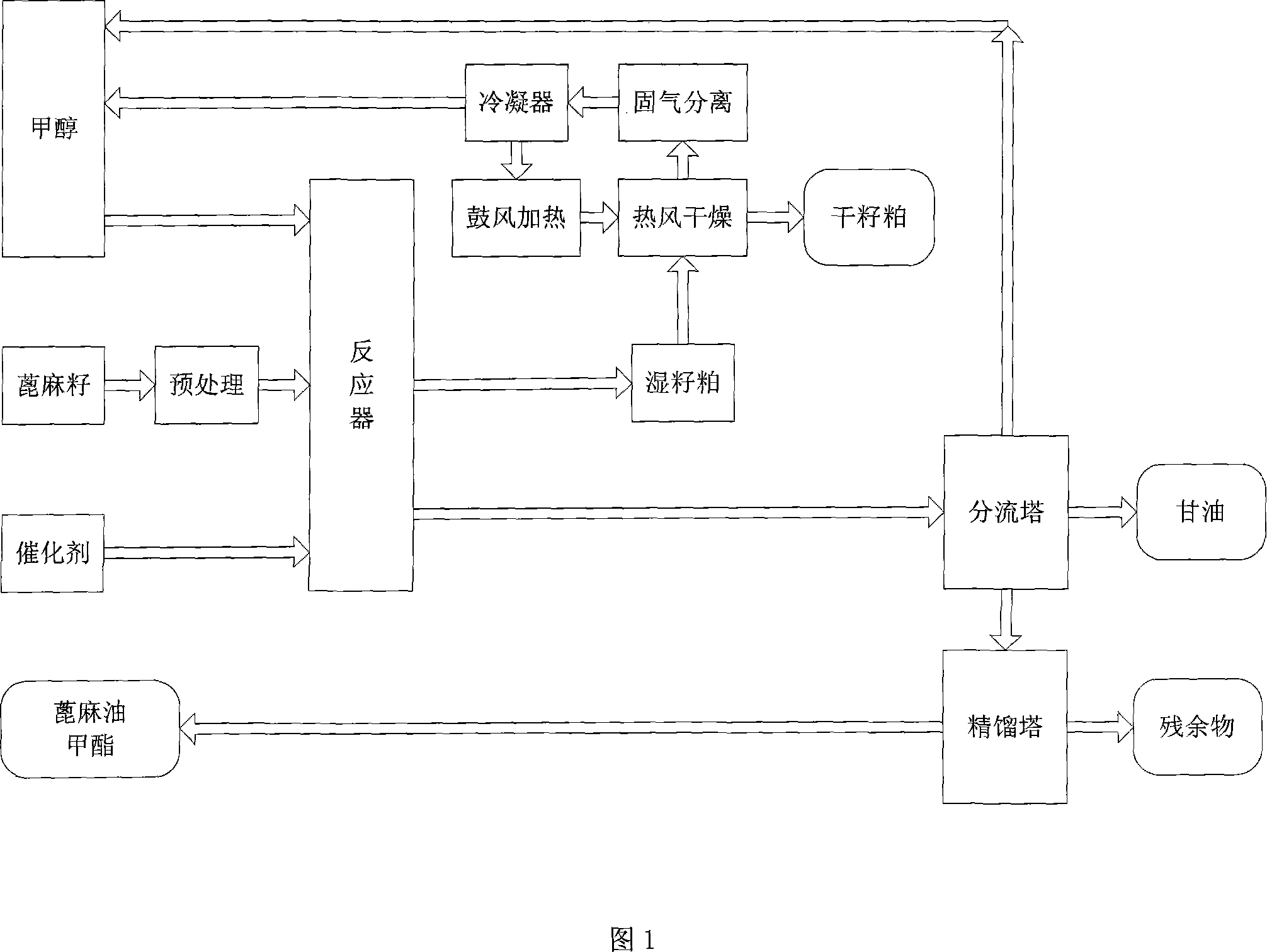

Image

Examples

Embodiment 1

[0014] Embodiment 1, graded and selected castor beans, after cleaning, peeling and squeezing, using potassium methylate as a catalyst, taking methanol as a leaching solvent and transesterification agent, the ratio of the moles of methanol and the pretreated castor beans Add the ingredients according to 3:1 and 0.5% of the catalyst together into the reaction device, and react at 30° C. for 0.5 hours under ultrasonic enhancement. After the castor oil methyl ester and glycerin are produced, the finished biodiesel is obtained through a filter device and a vacuum distillation device. During the experiment, the ultrasonic power was selected to be 8W / L, and the ultrasonic frequency was 20kHz.

Embodiment 2

[0015] The difference between embodiment 2 and embodiment 1 is that select sodium methylate as catalyzer, the ratio of the mole of methyl alcohol and castor bean after pretreatment is 6: 1, and catalyst mass percent is 0.5%, and temperature of reaction is 90 ℃, and the reaction time is For 1 hour, the selected ultrasonic power is 30W / L, and the ultrasonic frequency is 100kHz.

Embodiment 3

[0016] Embodiment 3 and embodiment 1 difference are that select sodium hydroxide as catalyzer, the ratio of the mole of methyl alcohol and castor bean after pretreatment is 9: 1, and catalyst mass percent is 1.2%, and temperature of reaction is 70 ℃, and the reaction time 6 hours, no physical enhancement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com