Undersaturation resin moulding by casting flowline operating device

A technology of resin pouring and flow operation, which is applied in the field of unsaturated resin pouring and forming flow operation devices, which can solve the problems of waste, rushing to operators, and slow operation speed, so as to reduce energy consumption, avoid potential safety hazards, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

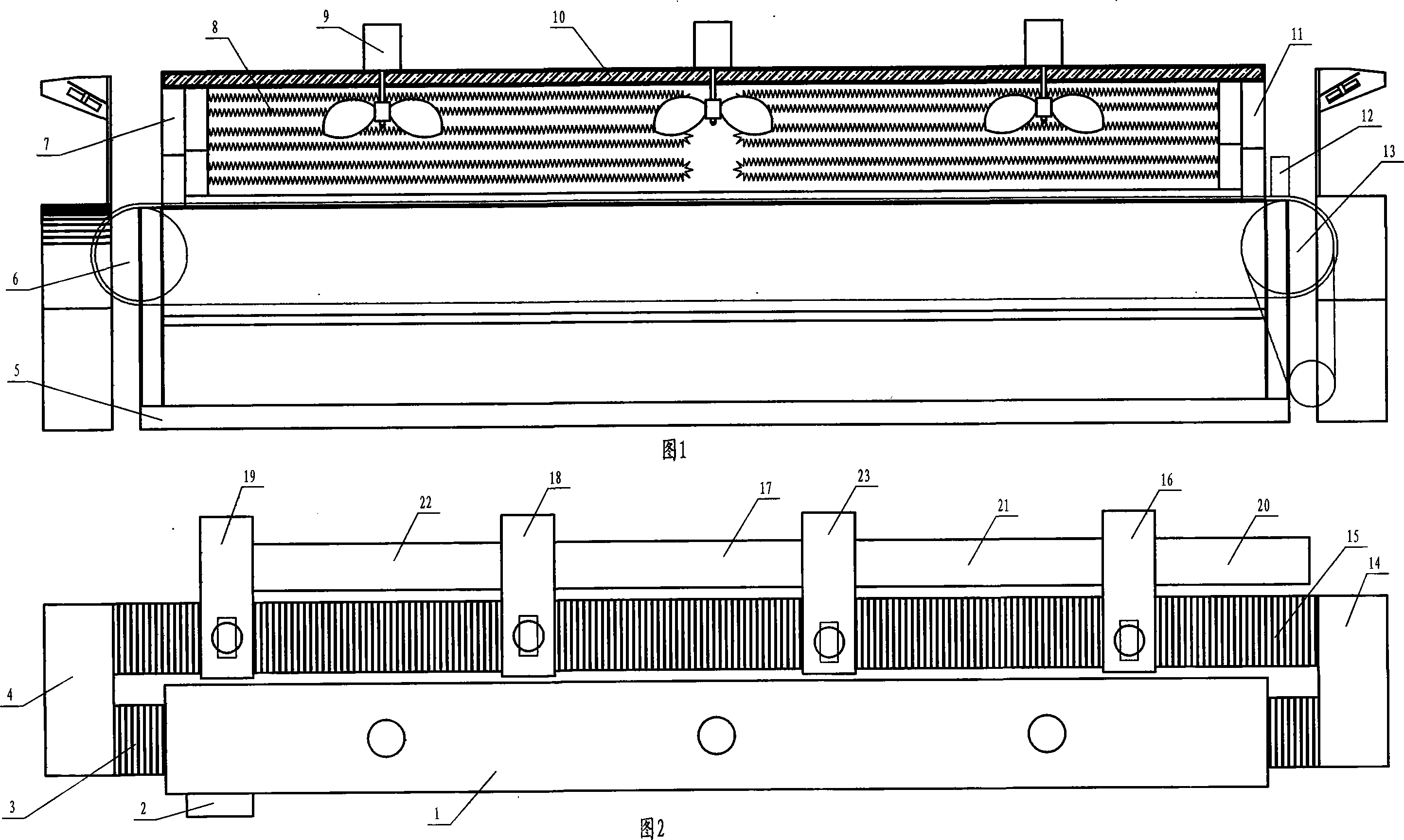

[0014] Embodiment: Referring to Fig. 1 and Fig. 2, the present invention is provided with several operating tables on one side of the machine base 5, a semi-closed oven 1 is arranged on the said machine base 5, and an electric control box 2 is arranged at one end of the semi-closed oven 1 , the bottom of the semi-closed oven 1 is provided with a built-in transmission chain 3, the semi-closed oven 1 above the built-in transmission chain 3 is provided with a heating wire group 8, and several forced circulation fans are arranged between the heating wire groups 8 in the semi-closed oven 1 9. An external drive chain 15 is set on the base 5 on the opposite side of the semi-closed oven 1 . Close to the exit door 7 of the semi-closed oven 1, the end of the built-in transmission chain 3 is provided with a first mold opening and closing operation table 14; along the outside of the external transmission chain 15 along the transmission direction, a second opening and closing operation tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com