Preparation of medicinal disintegrating agent with biological enzymatic isolation method

A technology of disintegrants and biological enzymes, which is applied in the field of preparation of pharmaceutical disintegrants by biological enzymatic hydrolysis, which can solve the problems of poor disintegration performance, restriction, and influence on the efficacy of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

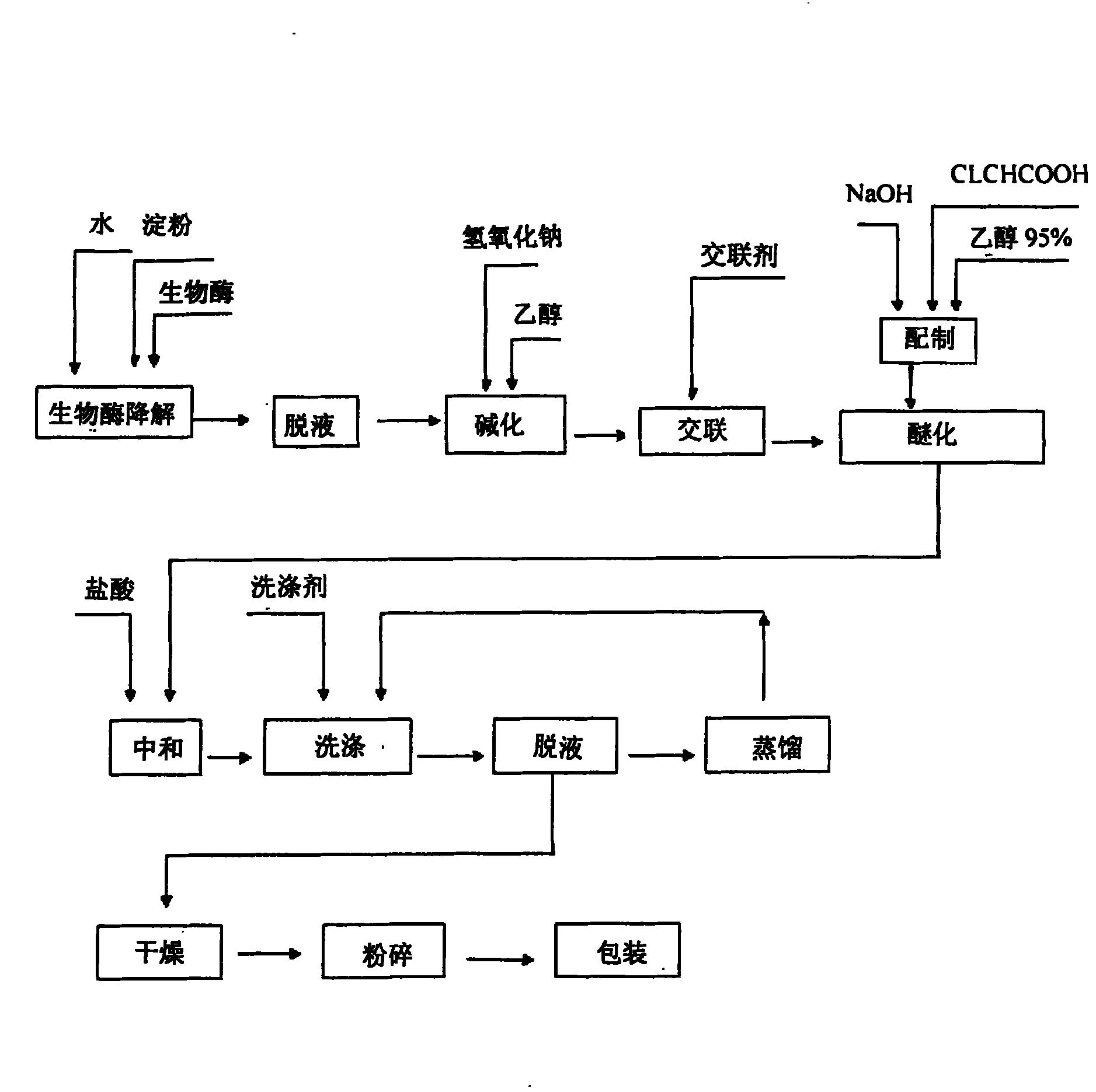

Method used

Image

Examples

Embodiment 1

[0037] In the stainless steel enzymatic hydrolysis kettle, add 100Kg of starch to make 40% starch milk, start stirring, add 5Kg of α-amylase, heat up to 50°C, react for 5 minutes, centrifuge and deliquify, then add to the stainless steel etherification kettle, Add 250Kg ethanol, 0.25Kg sodium trimetaphosphate, add dropwise 52Kg of 25% sodium hydroxide solution, alkalinize and crosslink for 1 hour at 40°C, and add etherification agent dropwise three times every 20 minutes (by, 50Kg ethanol, 30Kg Chloroacetic acid, 25% sodium hydroxide solution 52Kg preparation) carries out etherification, and jacket feeds hot water heating, and material temperature is maintained at 50 ℃, and after keeping warm for 10 hours, drops to room temperature, neutralization, washing, drying, Crushed into finished products.

Embodiment 2

[0039] Taking the preparation method of producing 1 ton of super disintegrant as an example, add 1000Kg of starch to make 40% starch milk in a stainless steel enzymatic hydrolysis kettle, start stirring, add 50Kg of α-amylase, heat up to 50°C, and react for 5 minutes. After centrifugation and dehydration, add to the stainless steel etherification kettle, add 2500Kg ethanol, 2.5Kg sodium trimetaphosphate, 520 kg of 25% sodium hydroxide solution, alkalinize and cross-link for 1 hour at 40 ° C, and divide it into three times with an interval of 20 minutes each time Etherifying agent (500 kilograms of ethanol, 300 kilograms of chloroacetic acid, 520 kilograms of 25% sodium hydroxide solution) is added dropwise to carry out etherification, and the jacket is passed into hot water for heating, and the material temperature is kept at 50° C. to room temperature, neutralized, washed, dried and pulverized to obtain the finished product.

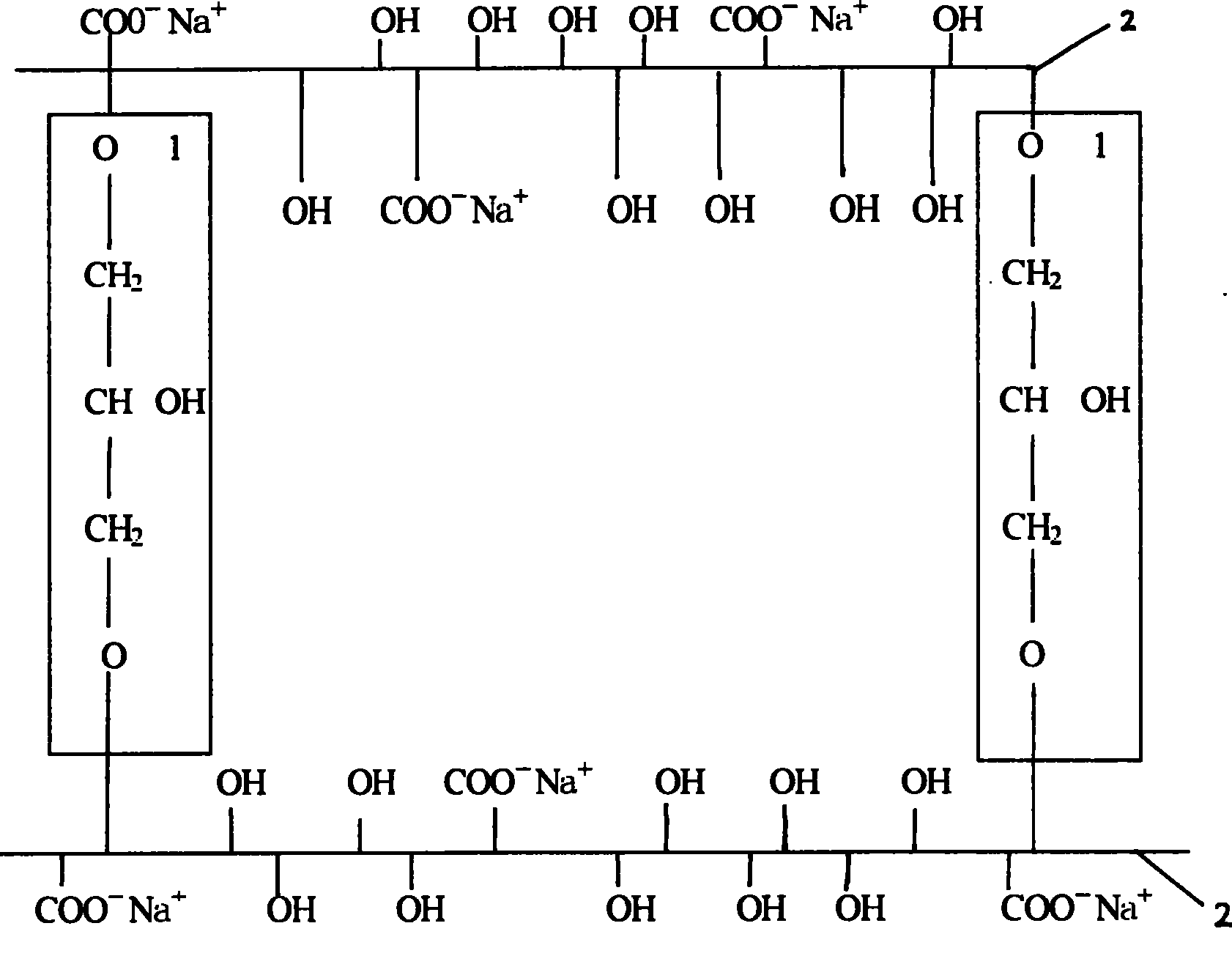

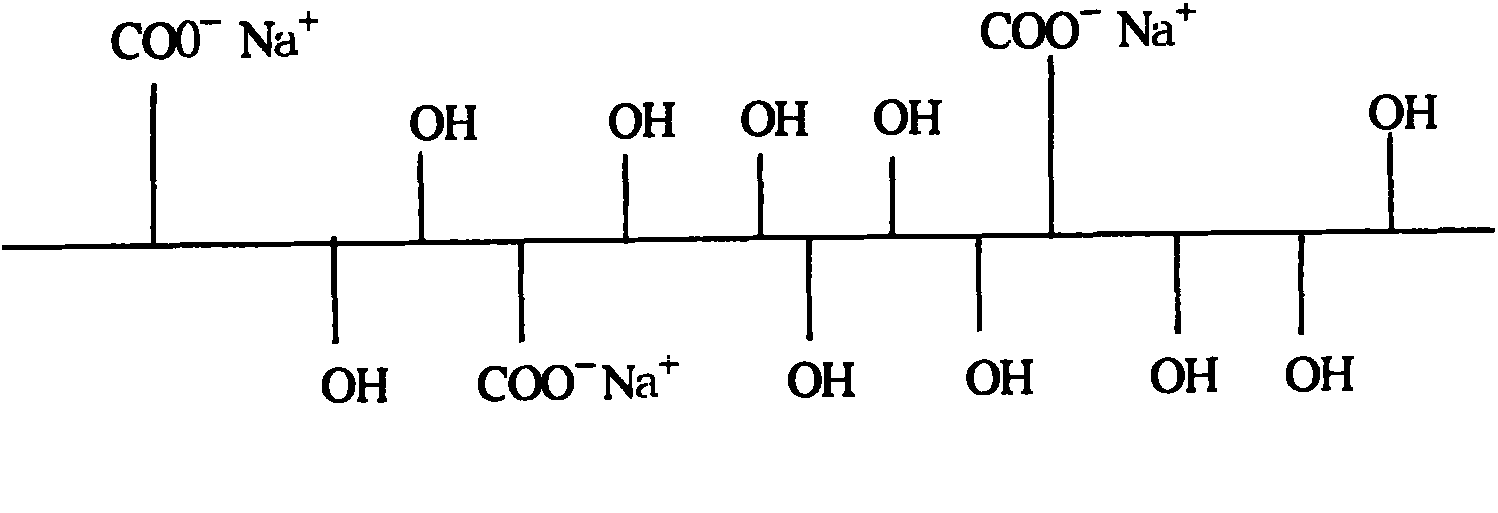

[0040] figure 2 is a schematic diagram of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com