Vision measuring method for projecting multiple frequency grating object surface tri-dimensional profile

A technology of object surface and measurement method, applied in the direction of measuring device, optical device, 3D image processing, etc., can solve the problems of single fringe phase noise, large number of gratings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] An embodiment of an optical three-dimensional measurement method and system proposed by the present invention is described as follows:

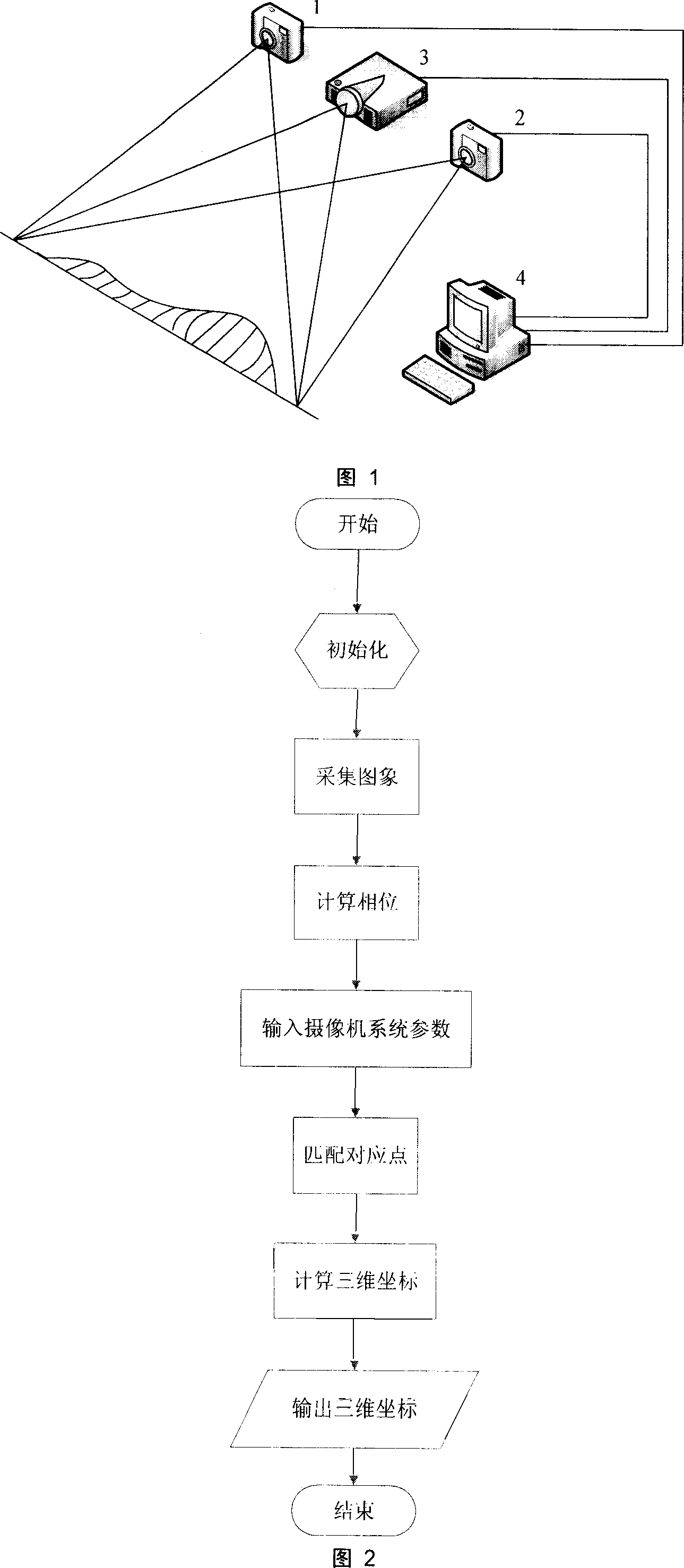

[0069] The measurement system of this embodiment is shown in Figure 1. The system consists of cameras 1 and 2, a projector 3, and a computer 4. The computer is P4 2.8GHz, two WAT 902H black and white CCD industrial cameras from WATEC, and two from Jiaheng Company. M10A OK series capture card, two domestic GDS 35 lenses, HP vp6315 projector.

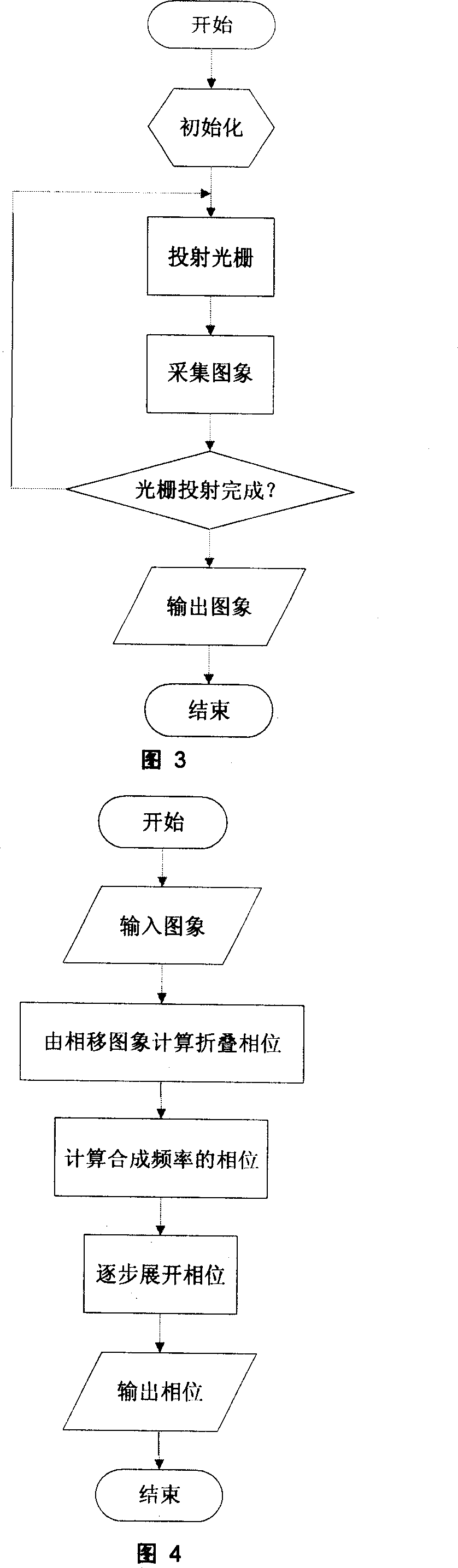

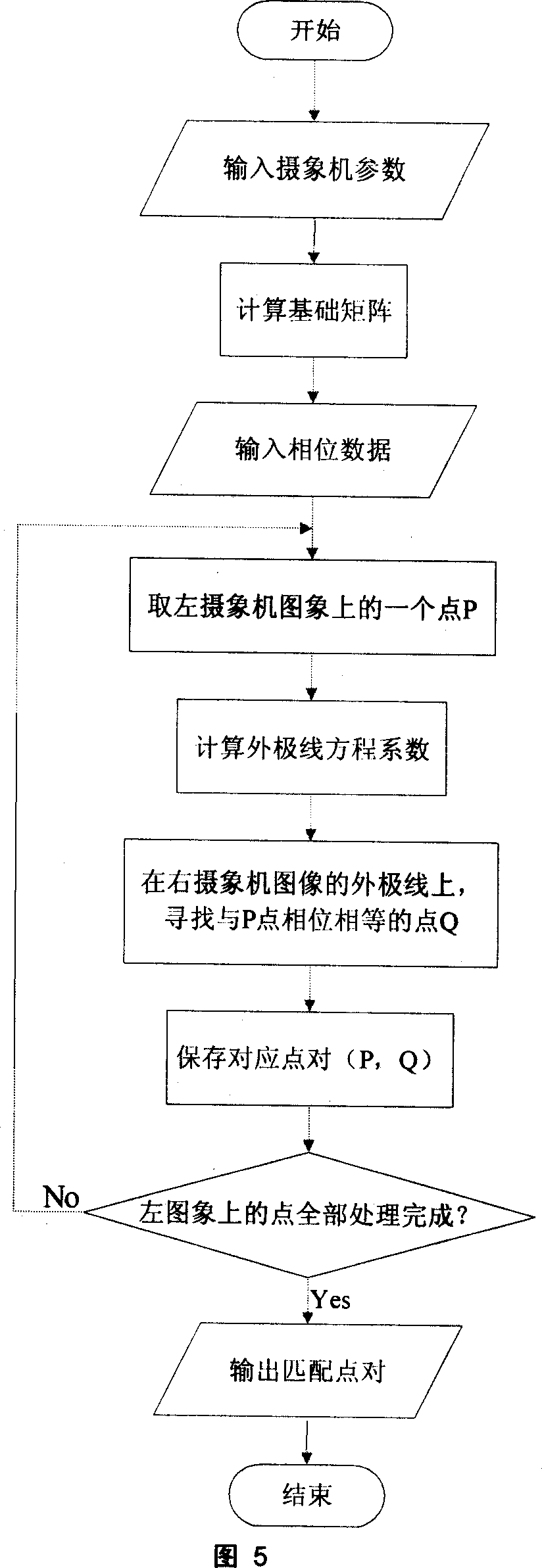

[0070] 1) Using a computer to generate three groups of virtual phase-shift gratings with fringe numbers of 120, 116, and 113 respectively, and using a projector to project the gratings onto the object;

[0071] 2) Two CCD cameras collect images and save them in the computer;

[0072] 3) Process the 12 images captured by each camera separately to obtain the phase value of each point;

[0073] 4) In order to make the calculation results more reliable, the modulation degree is used as the basis for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com