Screen type heated surface arrangement method for fluid bed boiler furnace

A panel-type heating surface and fluidized bed boiler technology, which is applied to steam boilers, boiler water pipes, water-tube steam boilers, etc., can solve problems such as uneven heat absorption of water-cooled walls, flow deviation, and impact on supercritical hydrodynamic safety. , to achieve the effect of increasing the layout space and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

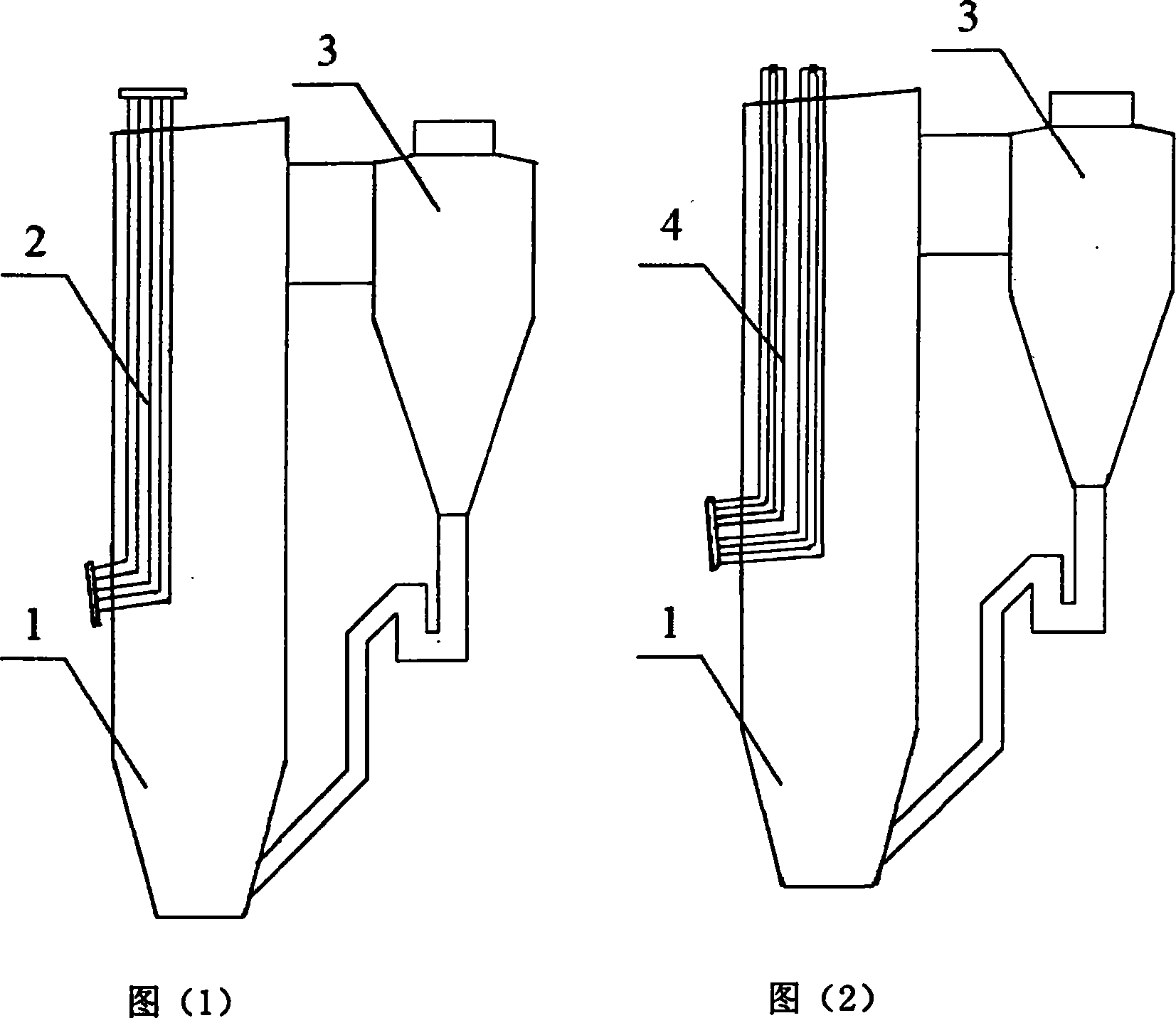

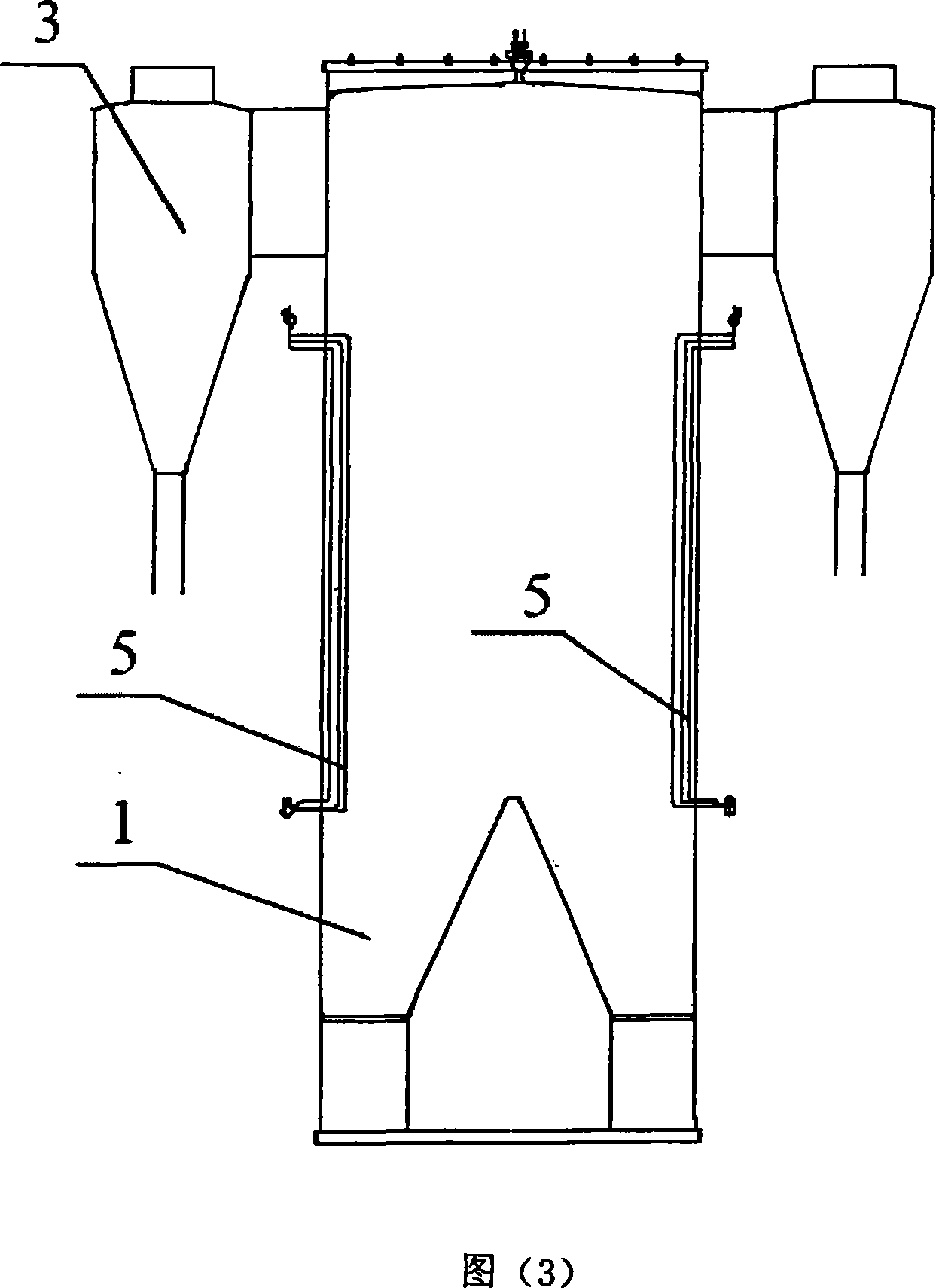

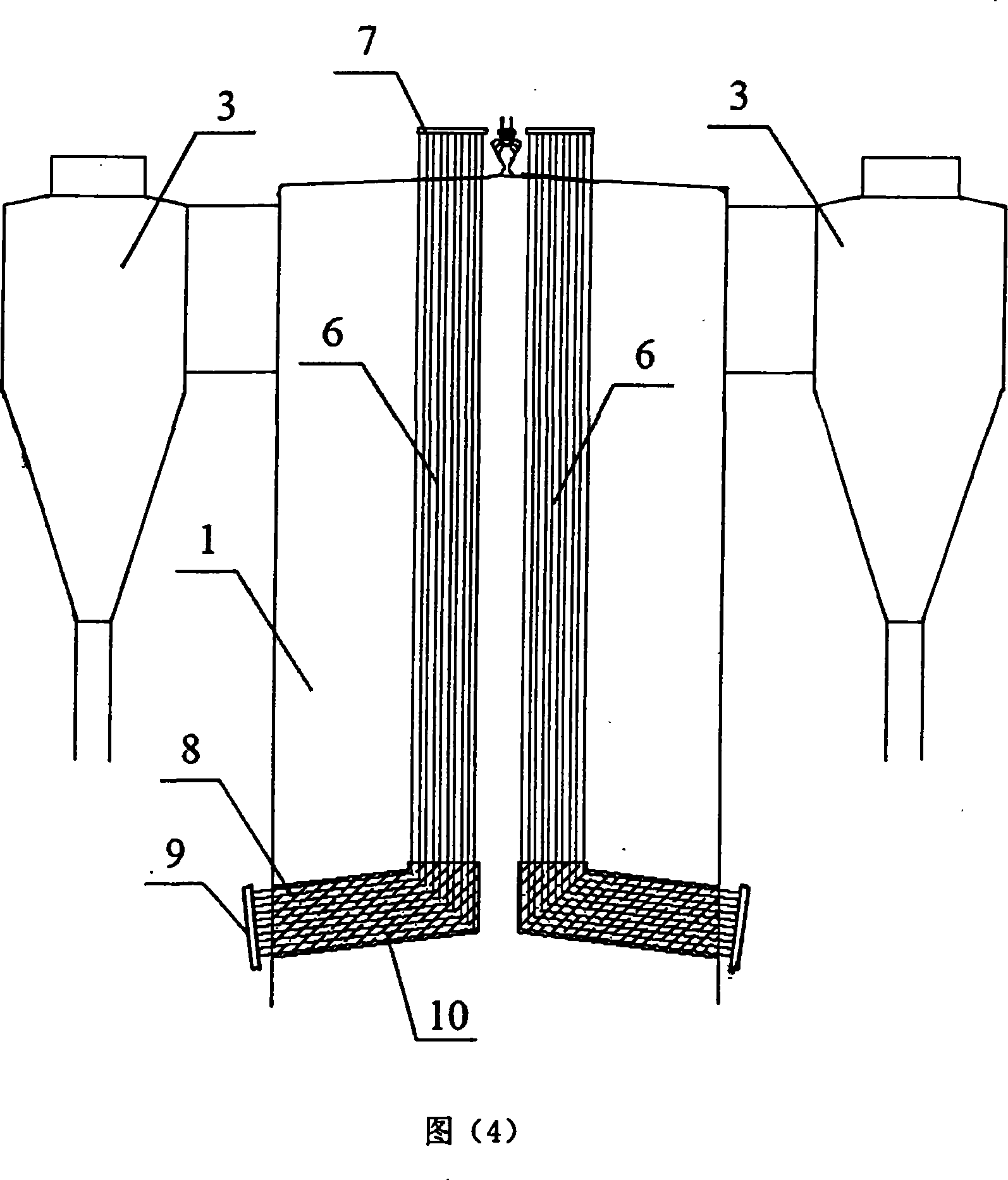

[0021] As shown in Figure 4, it is a schematic diagram of the panel heating surface structure of a fluidized bed boiler furnace, and the described panel heating surface structure of a fluidized bed boiler furnace is composed of a boiler 1, a separator 3 and a panel heating surface 6 At least one separator 3 is installed on both sides of the boiler 1, and the panel heating surface 6 is vertically installed in the middle of the boiler 1, the upper end passes through the furnace roof and connects to the outlet header 7, and the lower end passes through the water-cooled wall of the side wall of the boiler 1 and the inlet header 9 The connection, in order to prevent wear and tear, is composed of pipes on the panel heating surface 6, pins 8 and wear-resistant castables 10 in the oblique horizontal section through the wall and vertical flue flow direction, and the upper part is composed of tubes on the panel heating surface 6 and flat steel Membrane type composition. The panel-type h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com