Single extension suspended type hydraulic vertical prop

A hydraulic column and suspension technology, applied in the directions of pillars/supports, mining equipment, earthwork drilling, etc., can solve the problems of loose piston sealing, high production cost, and difficult production, and achieve good sealing, low cost, and weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

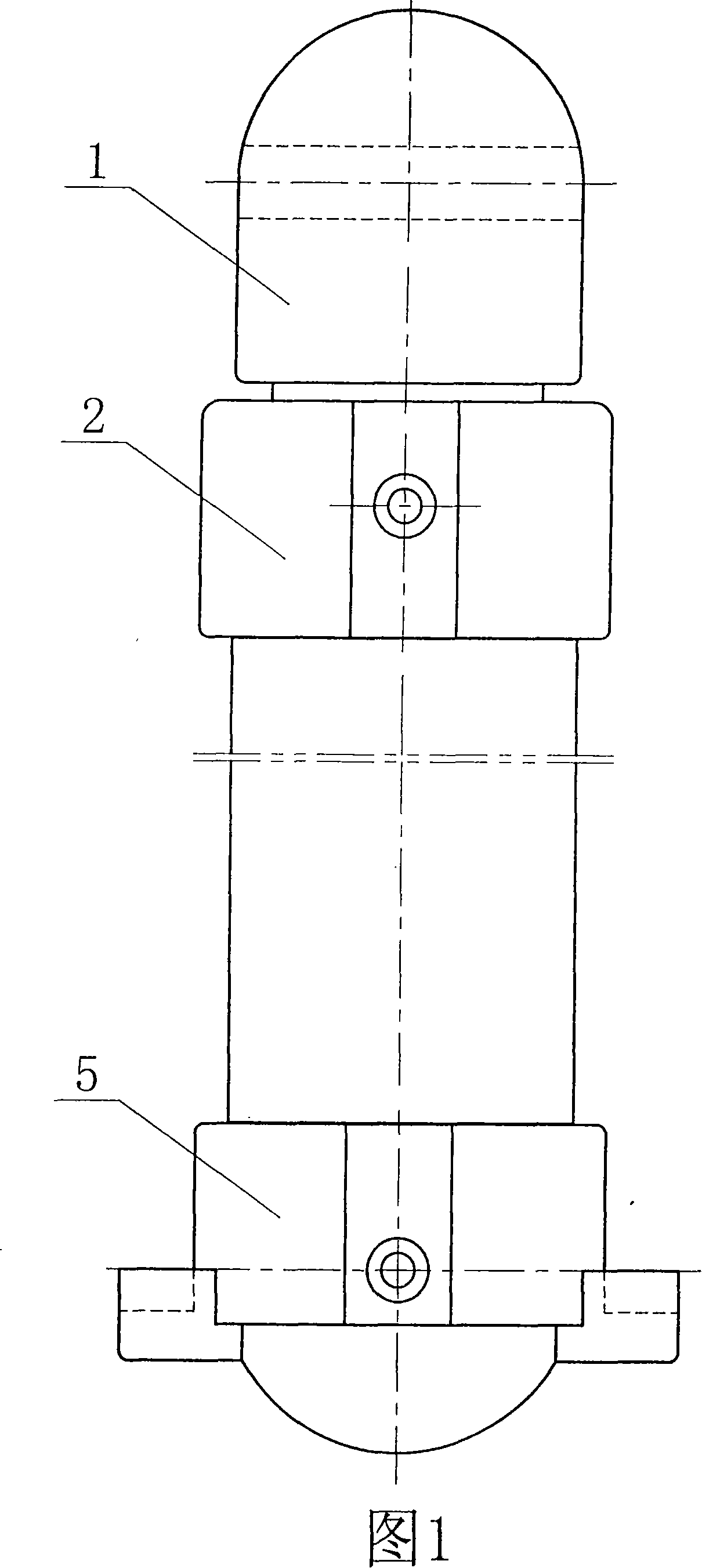

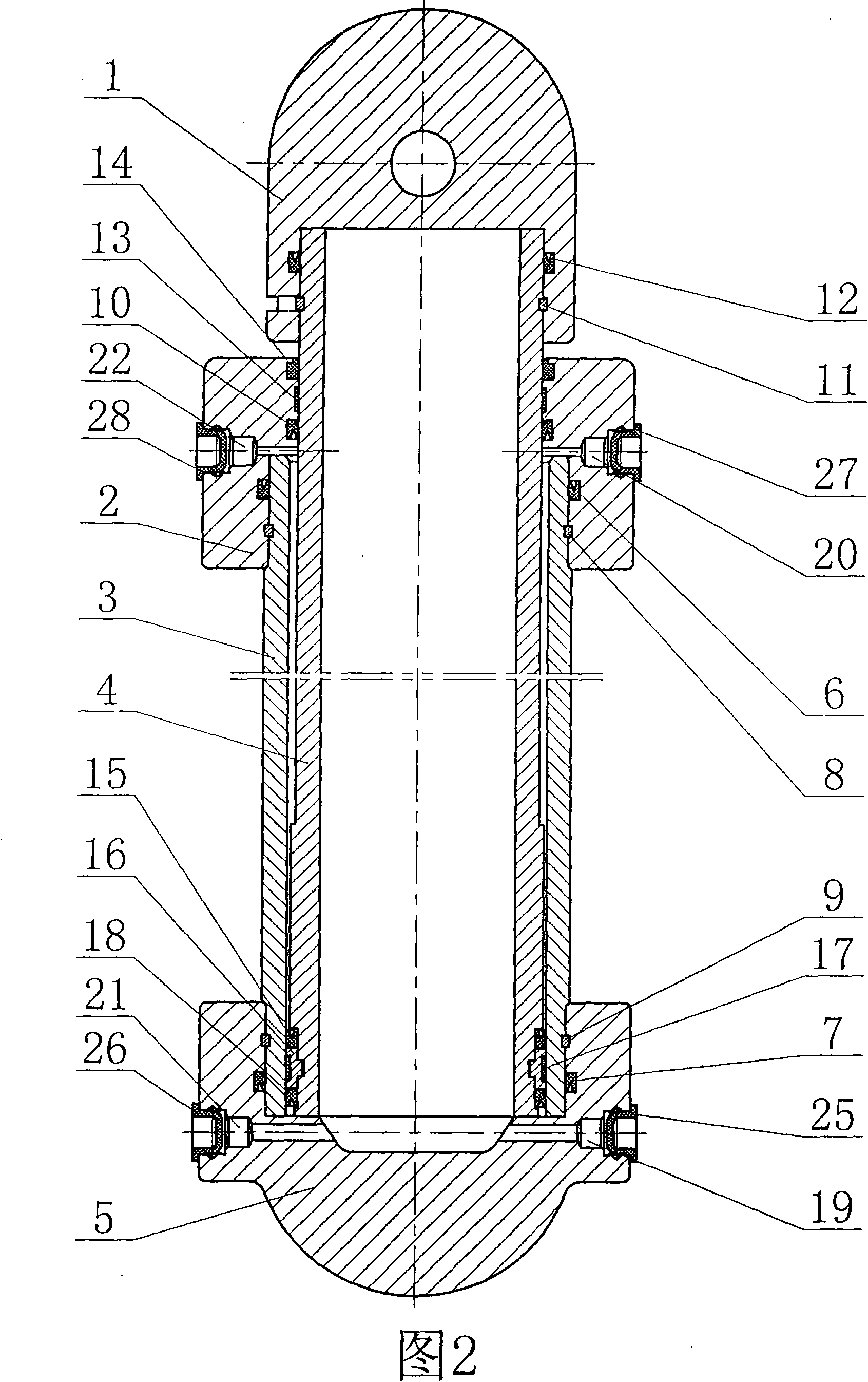

[0017] Embodiment 1, as shown in Figure 1 and Figure 2, the main upper end of the single telescopic suspension hydraulic column is a hemispherical top cover 1, cylinder liner 2, oil cylinder 3, live column 4, the lower end is a hemispherical base 5, clamp 16 and Composed of guide rings, seals, connecting steel wires, etc. The top cover 1 whose upper end is a hemisphere is arranged on the live post 4, and the top cover 1 is provided with a connecting hole connecting the top beam of the hydraulic support, which is a through hole; the contact surface between the top cover 1 and the live post 4 is provided with Sealing member 12, and be provided with the connecting steel wire 11 that top cover 1 and live post 4 are connected together; 5 is provided with two halves connecting blind holes connecting the bottom beam of the hydraulic support, and is provided with the inlet and outlet liquid through holes 19 and 21 connecting the oil cylinder 3 and the movable column 4, and oil seals 2...

Embodiment 2

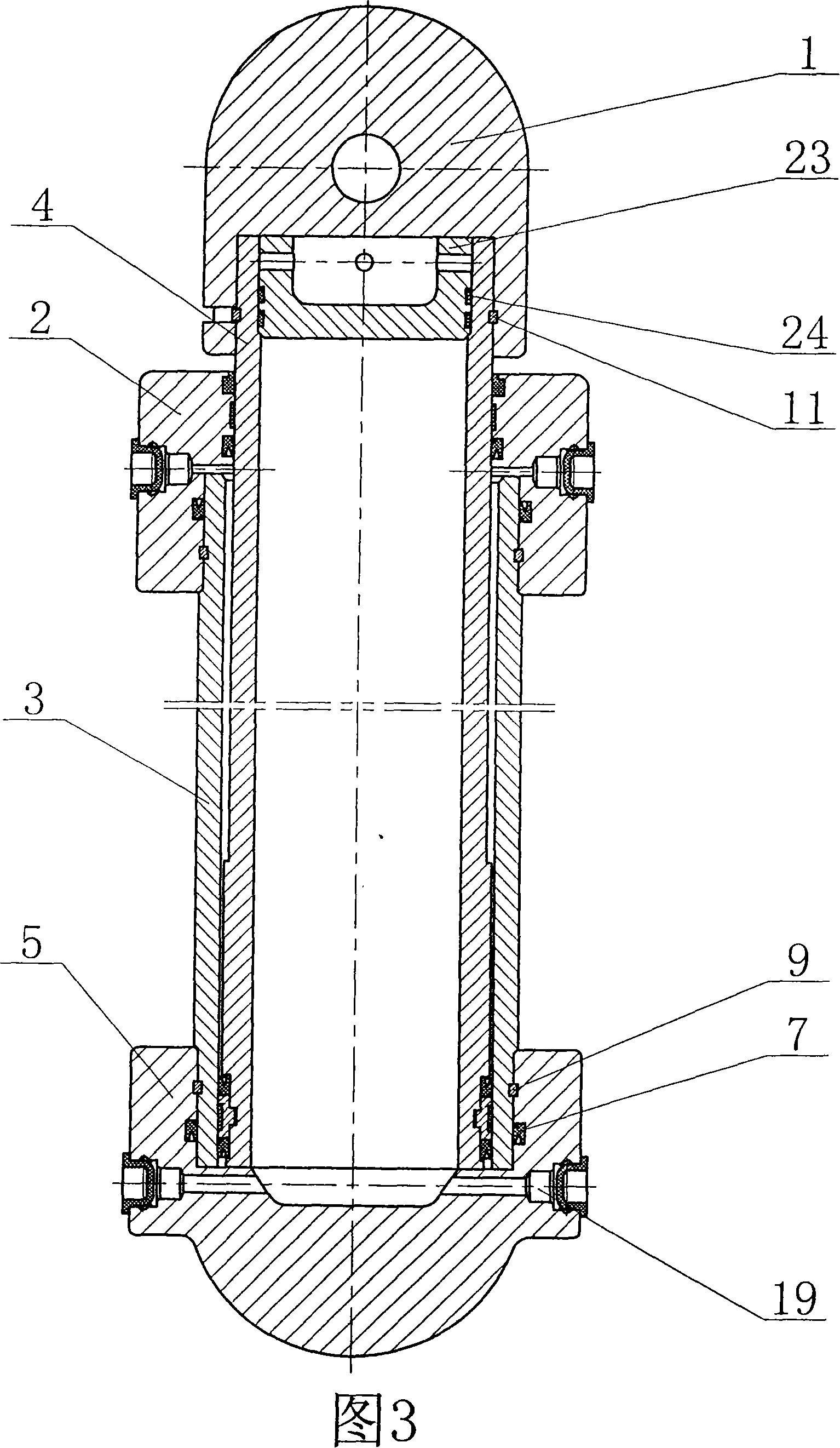

[0018] Embodiment 2, shown in Figure 3, is basically the same structure as Embodiment 1, the difference is that a suspension cover 23 is provided at the entrance of the inner diameter of the upper part of the live column 4, and one or more sets of seals are provided between the suspension cover 23 and the inner diameter of the live column 4. piece 24.

Embodiment 3

[0019] Embodiment 3, as shown in Fig. 4 and Fig. 5, is basically the same structure as Embodiment 1, except that the upper end of the top cover 1 is an ear plate, and the ear plate is provided with a connecting hole for connecting the top beam of the hydraulic support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com