Unmanned piling and taking technique for bulk cargo stock yard

A stockyard and stockpiling technology, which is applied in the field of bulk stockyard and bulk stockyard automation control stacking and fetching process, can solve the problems of low degree of automation, high labor intensity of operators, low operation efficiency, etc., to overcome automation low level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

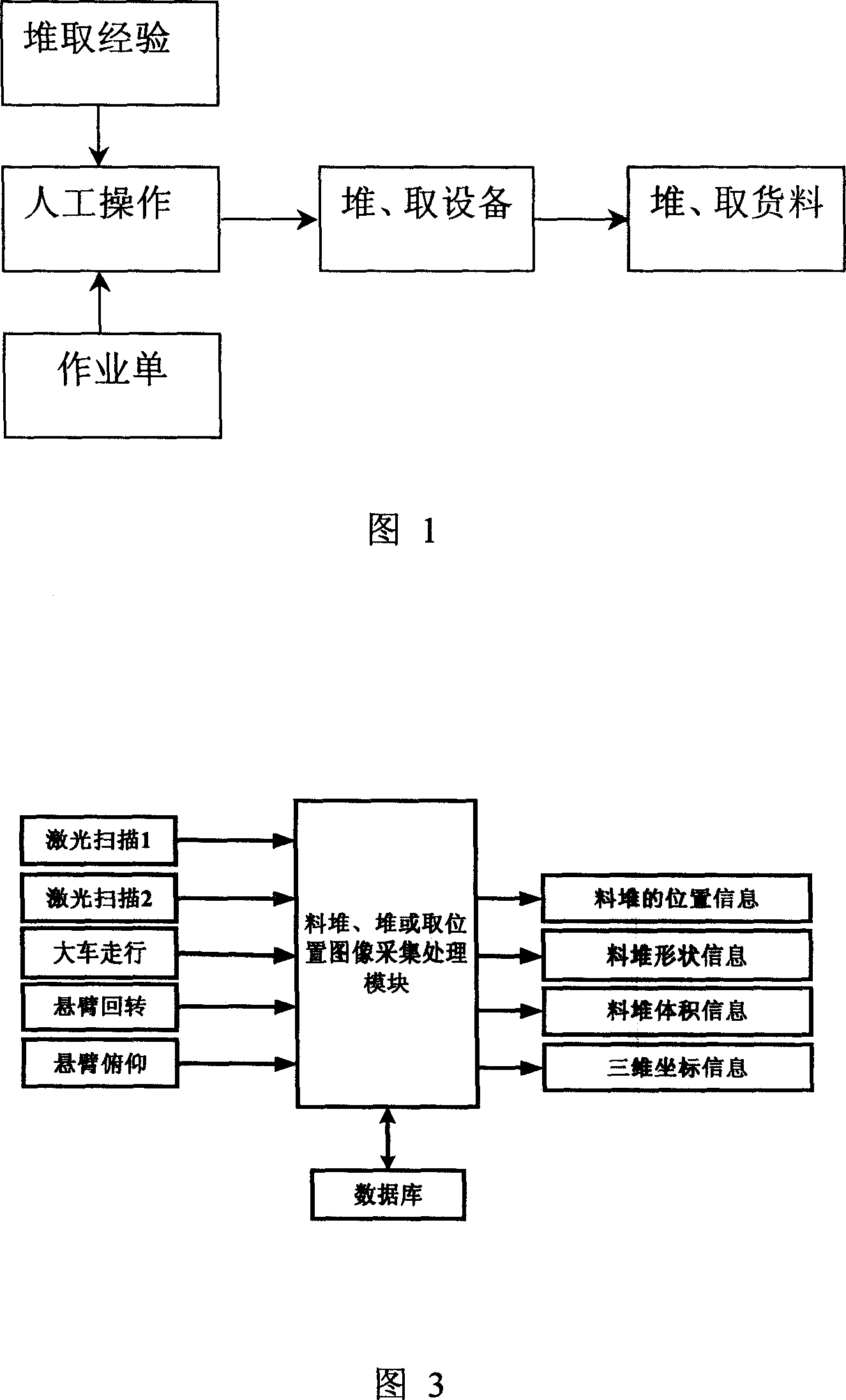

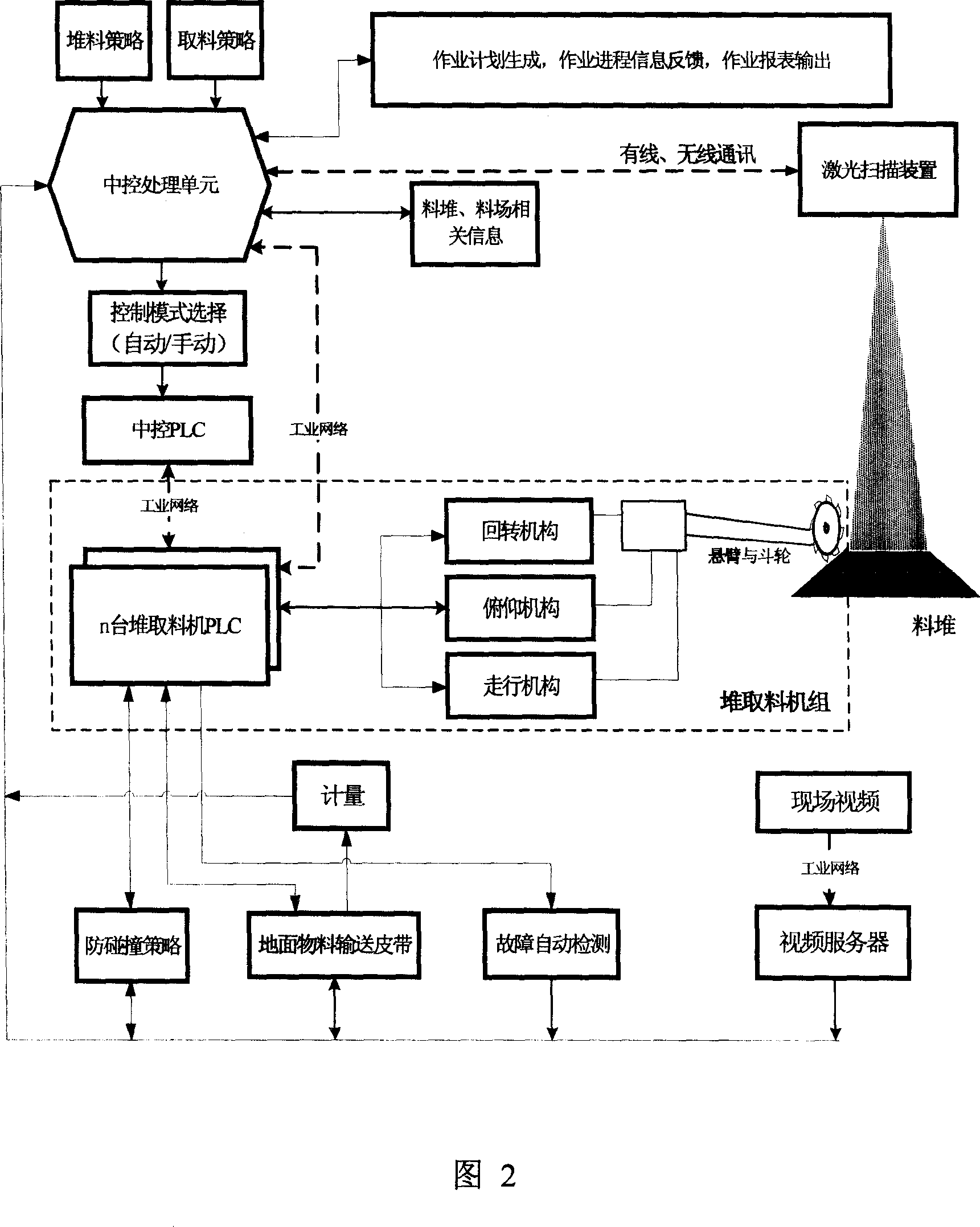

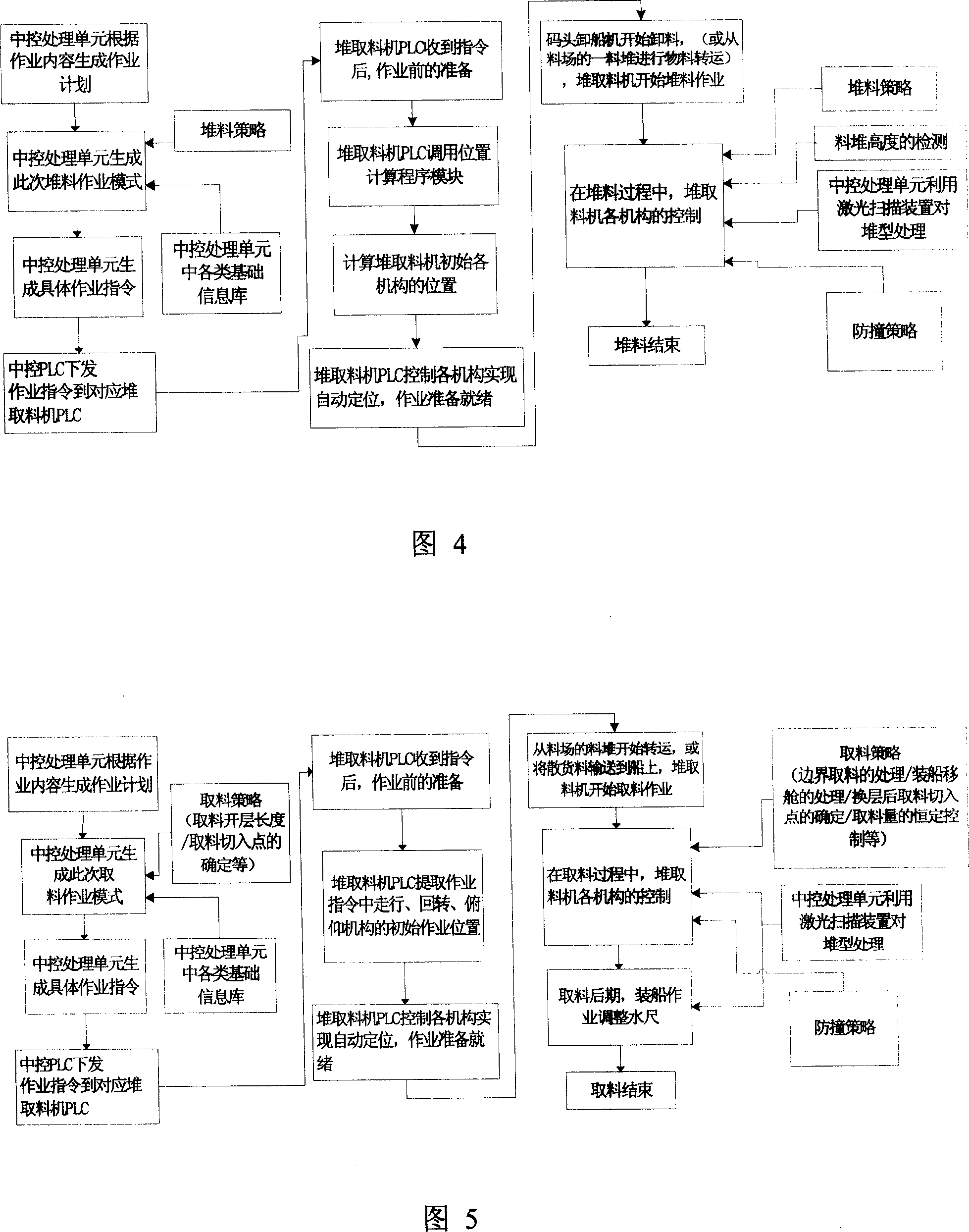

[0024] See Figure 2, an unmanned stacking and retrieving process for bulk cargo yards. The steps are as follows: the first step is to establish a database for the existing information. , Stacking strategy and retrieving strategy, the actual operation volume of stacking or retrieving is weighed by the belt scale of the ground material transmission;

[0025] The second step is to send the relevant job content including the job type and planned job volume to the central control processing unit, and the central control processing unit generates job instructions and automatic stacking and retrieving operations according to the stacking strategy and retrieving strategy stored in the database. Mode and preparation for automatic stacking and reclaiming operation process control instructions;

[0026] The third step is to select the automatic stacking and reclaiming operation mode, and to automatically or manually select the operation process control;

[0027] The fourth step is to se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com