Intelligent lettering mechanism of belt-film transporting system for producing large transfusion soft bag

A conveying system and printing mechanism technology, applied in typewriters, printing, printing devices, etc., can solve the problems of high printing cost, low utilization rate of ribbon 29, high energy consumption, etc., and achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

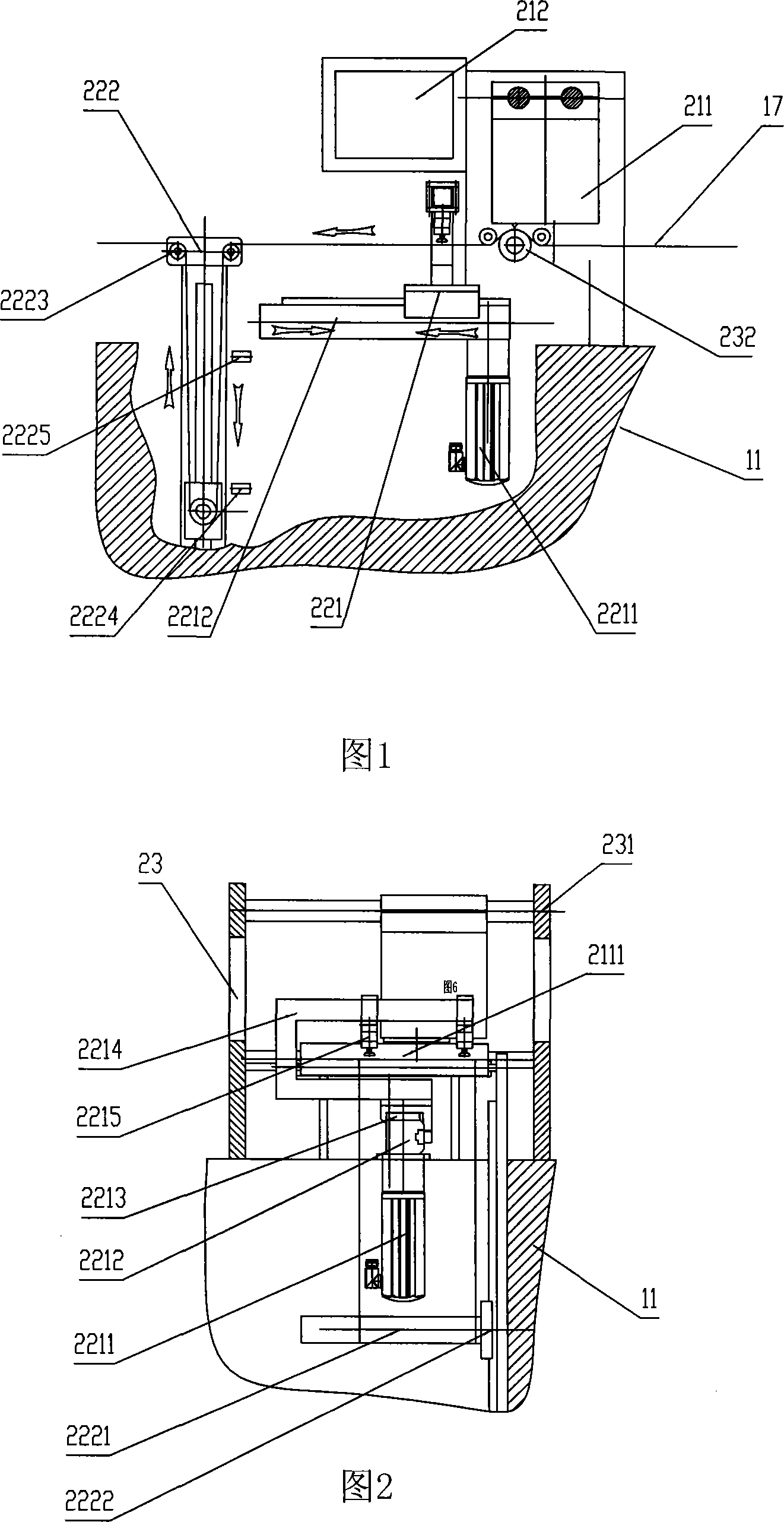

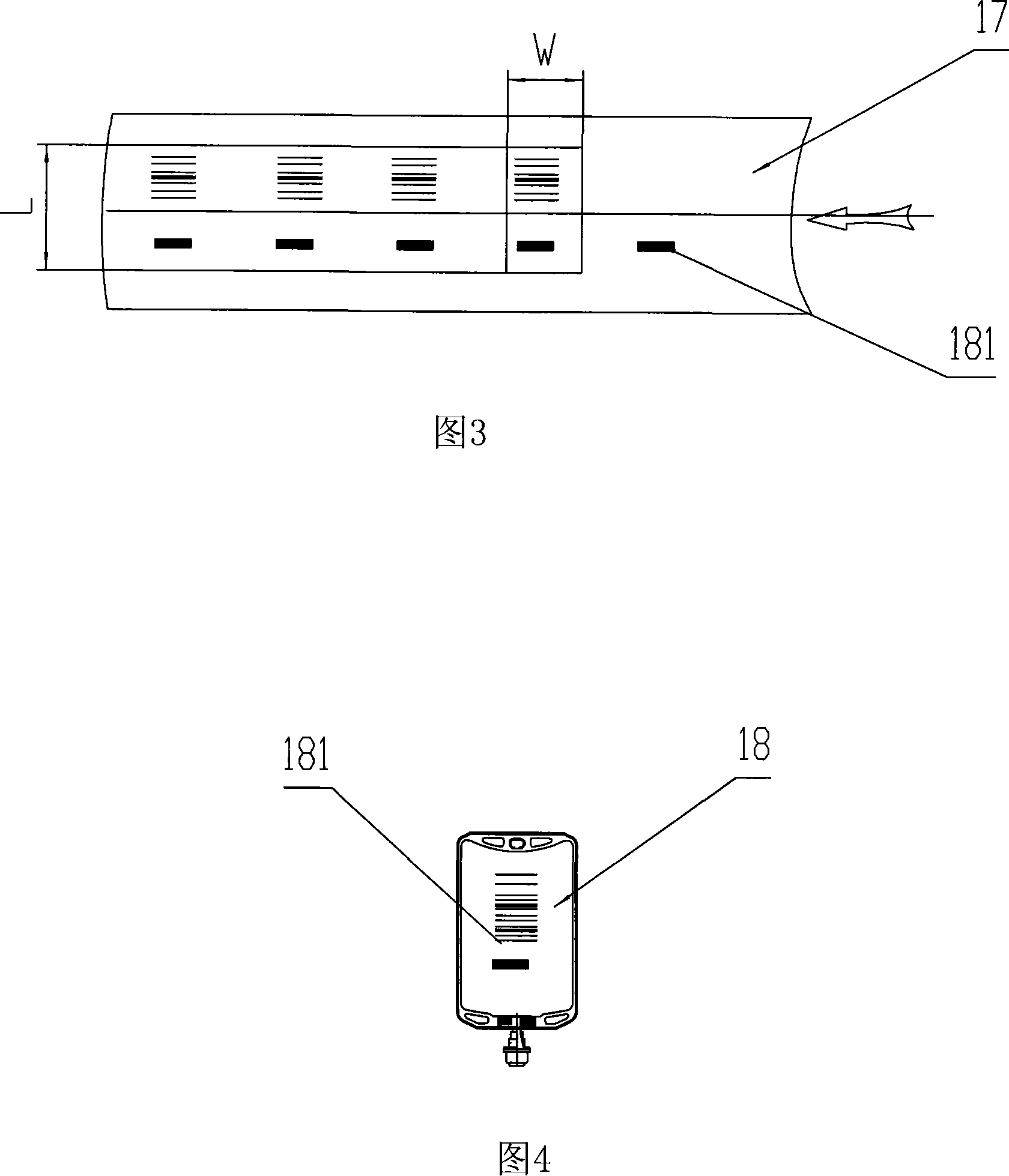

[0050] As shown in Figures 1 and 2, the thermal transfer intelligent coding system 21 is fixed on the wallboard 231 of the printing frame 23, and the width direction of the print head 2111 of the printing body 211 is the same as the width direction of the bag-making film 17. The film conveying system 22 is installed on the frame 11, wherein the film feeding device 221 is installed in front of the printing body 211 with reference to the moving direction of the bag-making film, and the film tensioning device 222 is installed in front of the film feeding device as shown in Figure 1 . When starting to work, the film-drawing frame 2214 of the film feeding device 221 is located at the right end, the clamping cylinder 2215 presses the bag-making film 17 downward, and the electric motor 2211 drives the film-drawing frame 2214 on the linear driver 2212 to take the bag-making film 17 to the left sports. When the film-feeding device 221 sends the bag-making film 17 to the film support r...

Embodiment approach 2

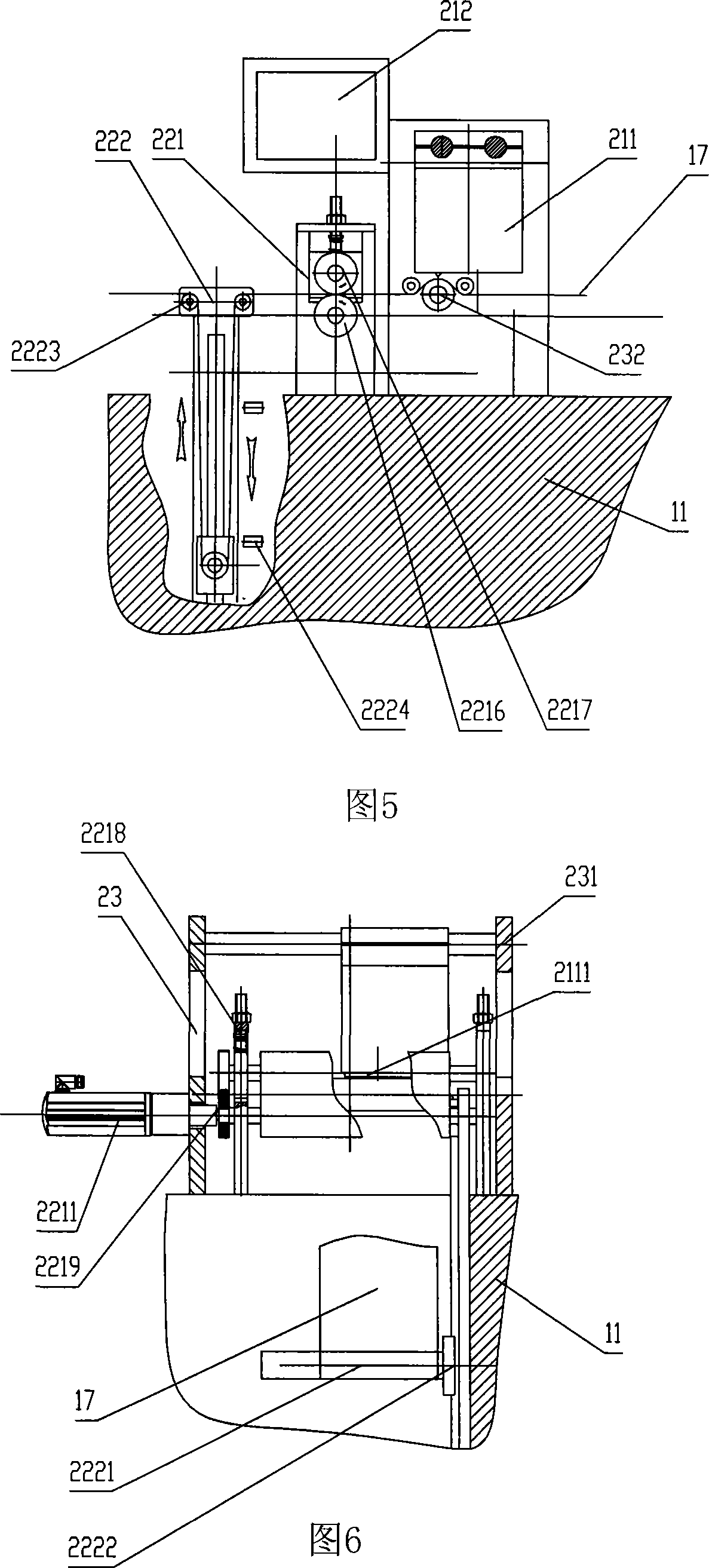

[0053] As shown in FIGS. 5 and 6 , the thermal transfer intelligent coding system 21 is fixed on the wallboard 231 of the printing frame 23 , wherein the width direction of the print head 2111 of the printing body 211 is the same as the width direction of the bag-making film 17 . The film feeding device 221 is installed in front of the printing body 211 with reference to the moving direction of the bag-making film, and the film tensioning device 222 is installed in front of the film feeding device as shown in FIG. 5 . The film feeding device 221 is composed of an electric motor (servo motor or stepping motor) 2211 , a first film feeding roller 2216 , a second film feeding roller 2217 , a pressure regulator 2218 and a transmission system 2219 . The pressure regulating device 2218 can adjust the pressing force of the first film feeding roller 2216 and the second film feeding roller 2217 on the bag-making film 17 . The transmission system 2219 transmits the power on the first fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com