Laminated coil part

A technology of stacking coils and components, applied in the direction of coil manufacturing, electrical components, magnetic objects, etc., can solve the problems of inability to prevent the decrease of impedance |Z|

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0020] (first embodiment, reference Figure 1 to Figure 6 )

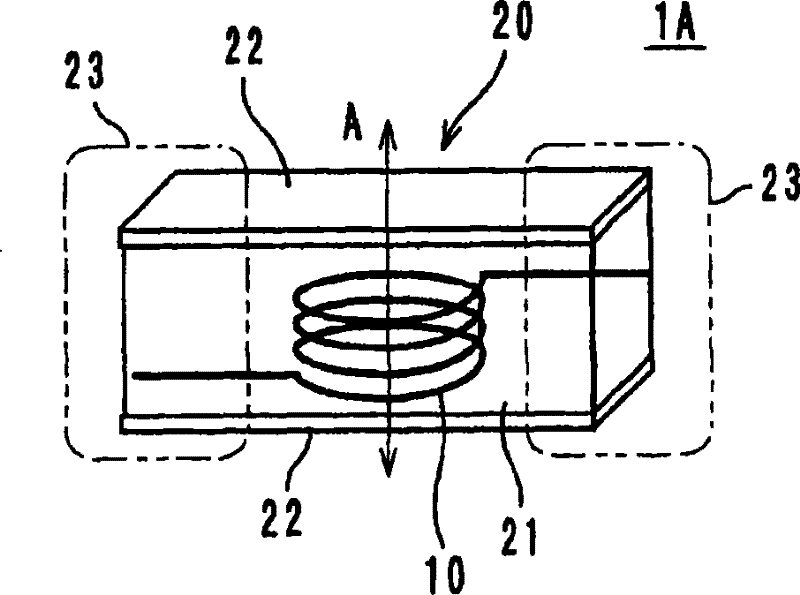

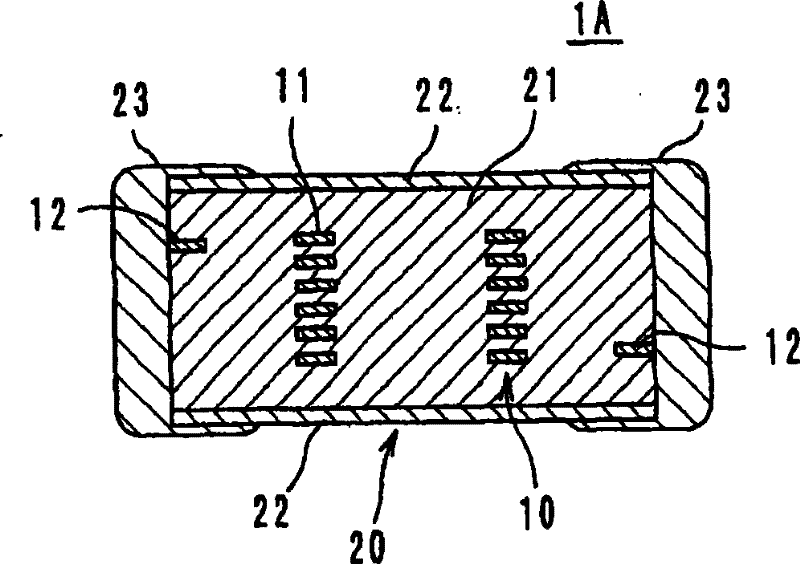

[0021] The laminated coil component 1A as the first embodiment of the present invention is as figure 1 As shown, there is a laminated body body 21 made of a first ferrite in which the coil 10 is provided, and a laminated body made of a second ferrite formed at both ends (upper and lower parts) in the coil axis direction A The end portion 22 , the left and right ends of the laminated body 20 are provided with external electrodes 23 . figure 2 Its section is shown.

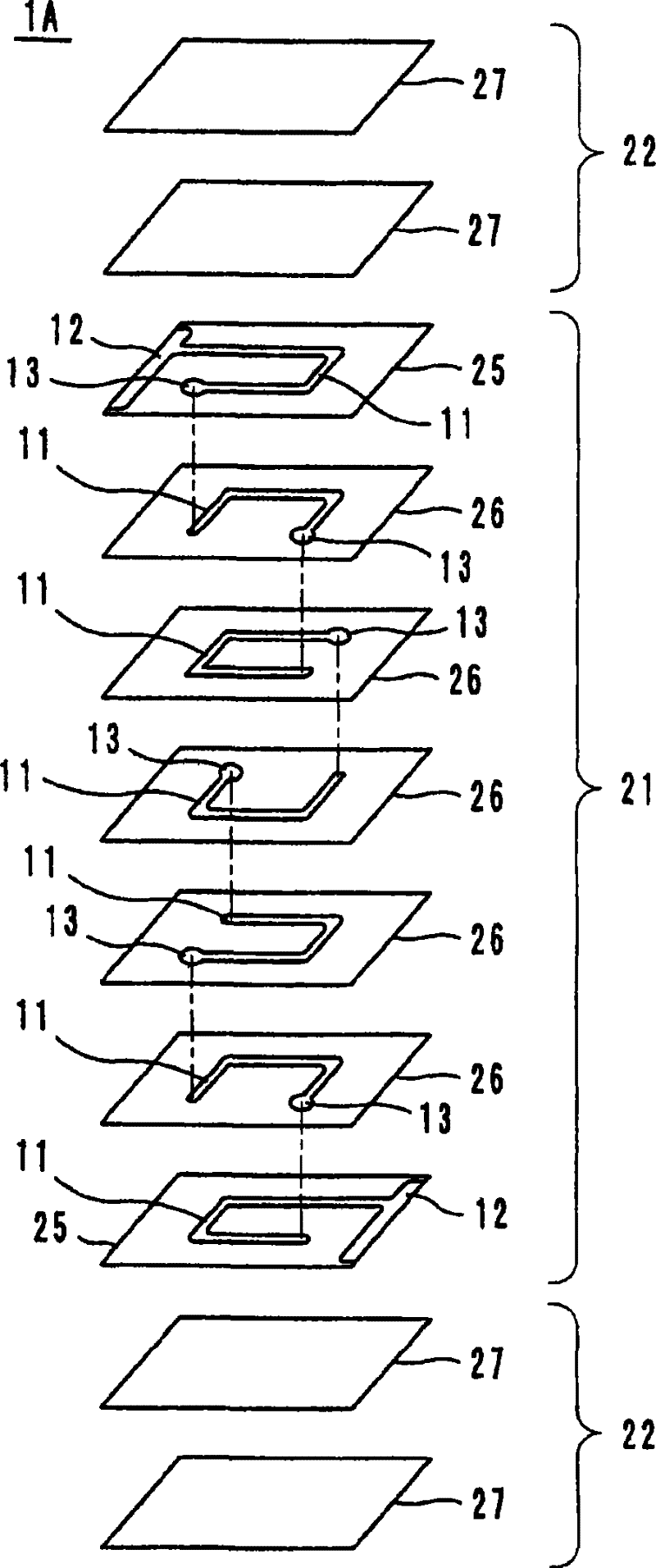

[0022] In more detail, as image 3 As shown, ferrite sheet 25 on which coil conductor 11 and lead-out electrode 12 are formed, ferrite sheet 26 on which coil conductor 11 is formed in a predetermined pattern, and blank ferrite sheet 27 are laminated. The sheets 25 and 26 are formed of first ferrite and form the above-mentioned main body 21 . The sheet 27 is formed of second ferrite, and forms the above-mentioned end portion 22 . Each coil conductor...

no. 2 Embodiment

[0041] (the second embodiment, refer to Figure 7 and Figure 8 )

[0042] Figure 7 In the illustrated laminated coil component 1B, the coil 50 is arranged in the laminated body body 61 formed of the first ferrite so that the coil 50 is arranged so that the coil axis direction A is parallel to the mounting surface 5, and the coil axis direction A is parallel to the mounting surface 5. The elements of the end portions of the laminated body 62 formed of the second ferrite are provided at both ends (the left and right end portions of the laminated body 60).

[0043] In more detail, as Figure 8 As shown, both end portions of the ferrite sheets 65 to 68 are formed of the second ferrite having a large shrinkage ratio, and the other portions are formed of the first ferrite. The coil conductor 51, the lead-out electrode 52, and the via-hole conductor 53 are formed in the ferrite sheet 65, the via-hole conductor 53 is formed in the ferrite sheet 66, and the coil conductor 51 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com