Automatic speed derailleur for electric vehicle

A technology of automatic transmission and electric vehicle, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of excessive battery discharge current, reduced battery life, limited driving speed, etc., to prolong the service life , Enhanced adaptability, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

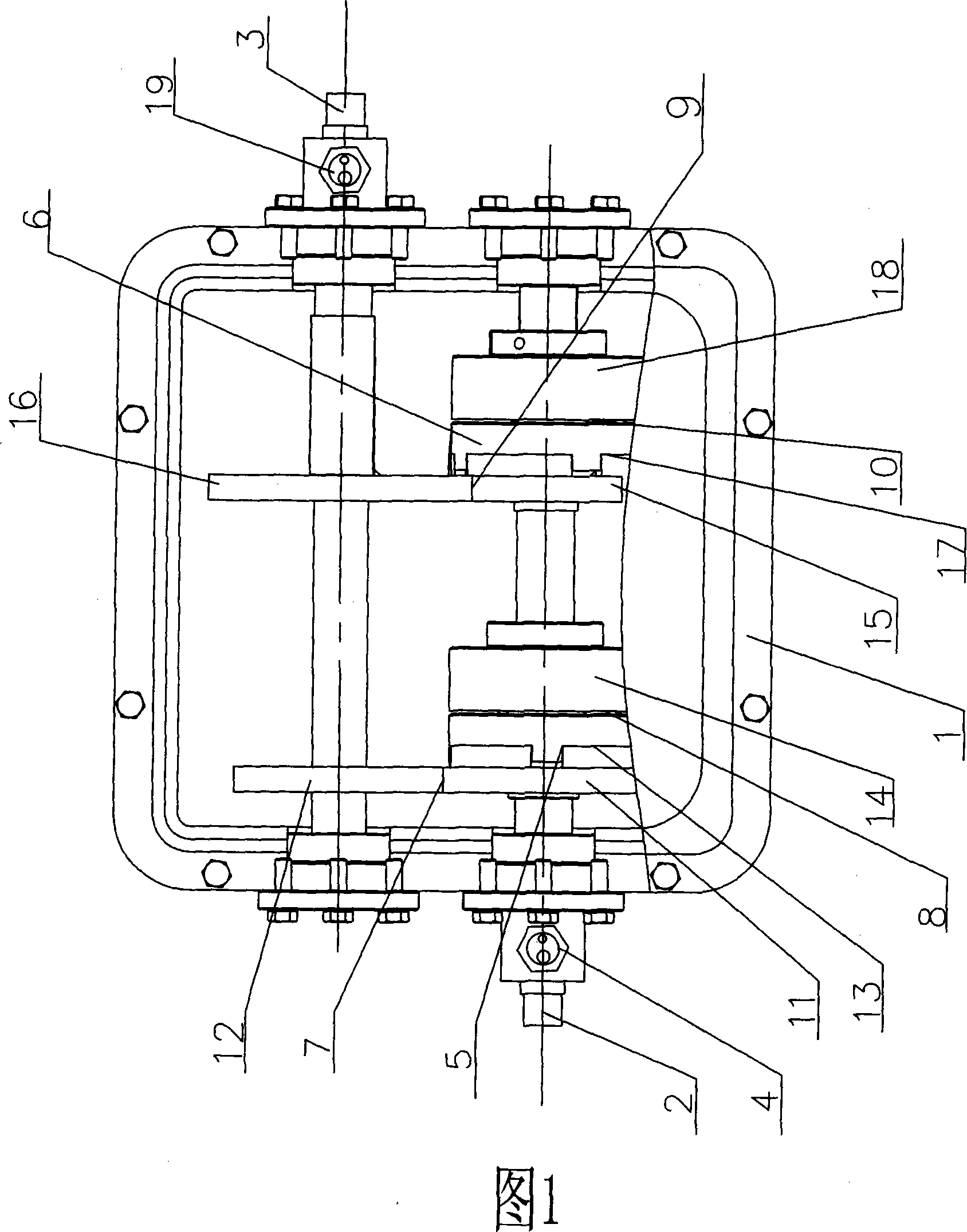

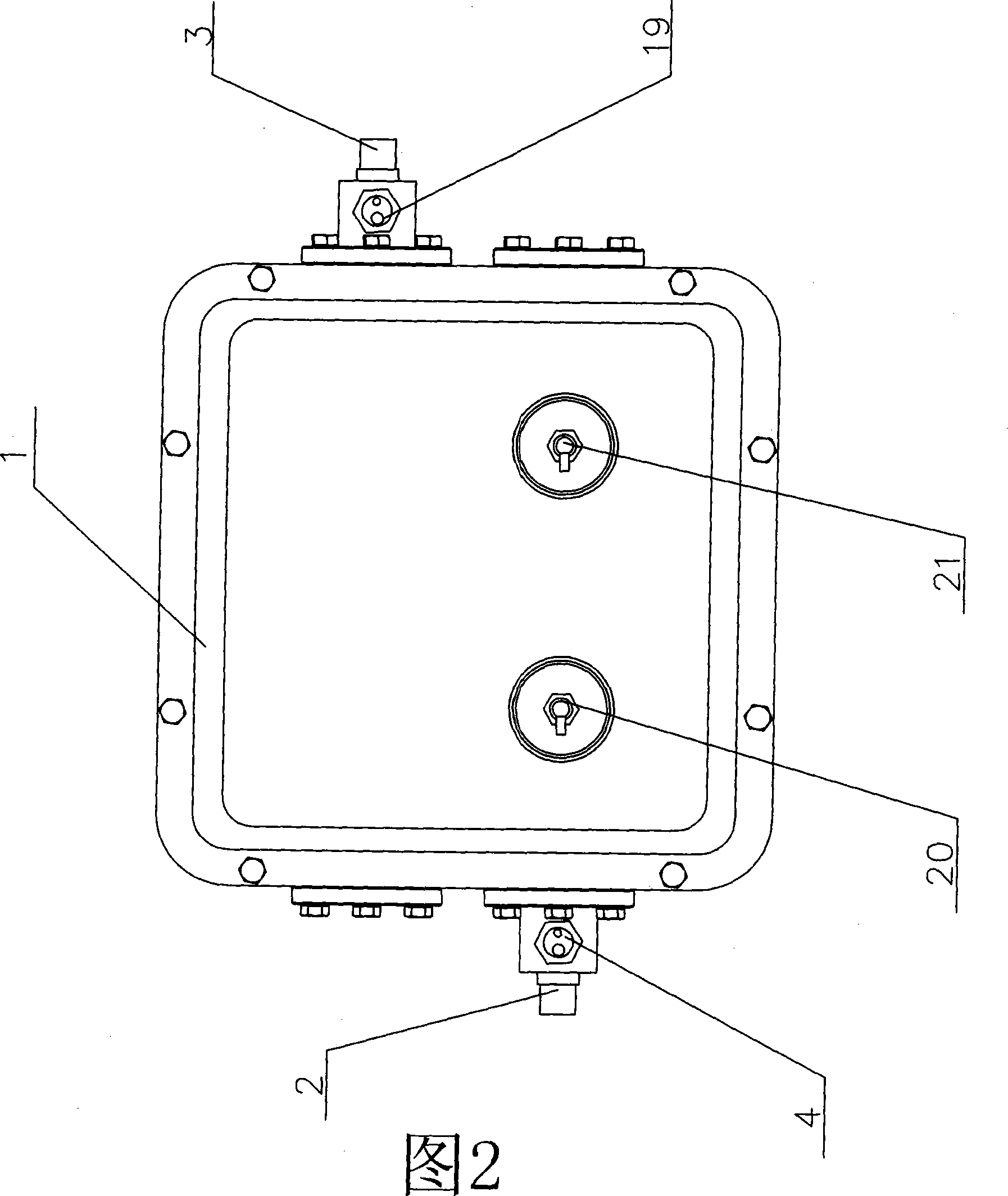

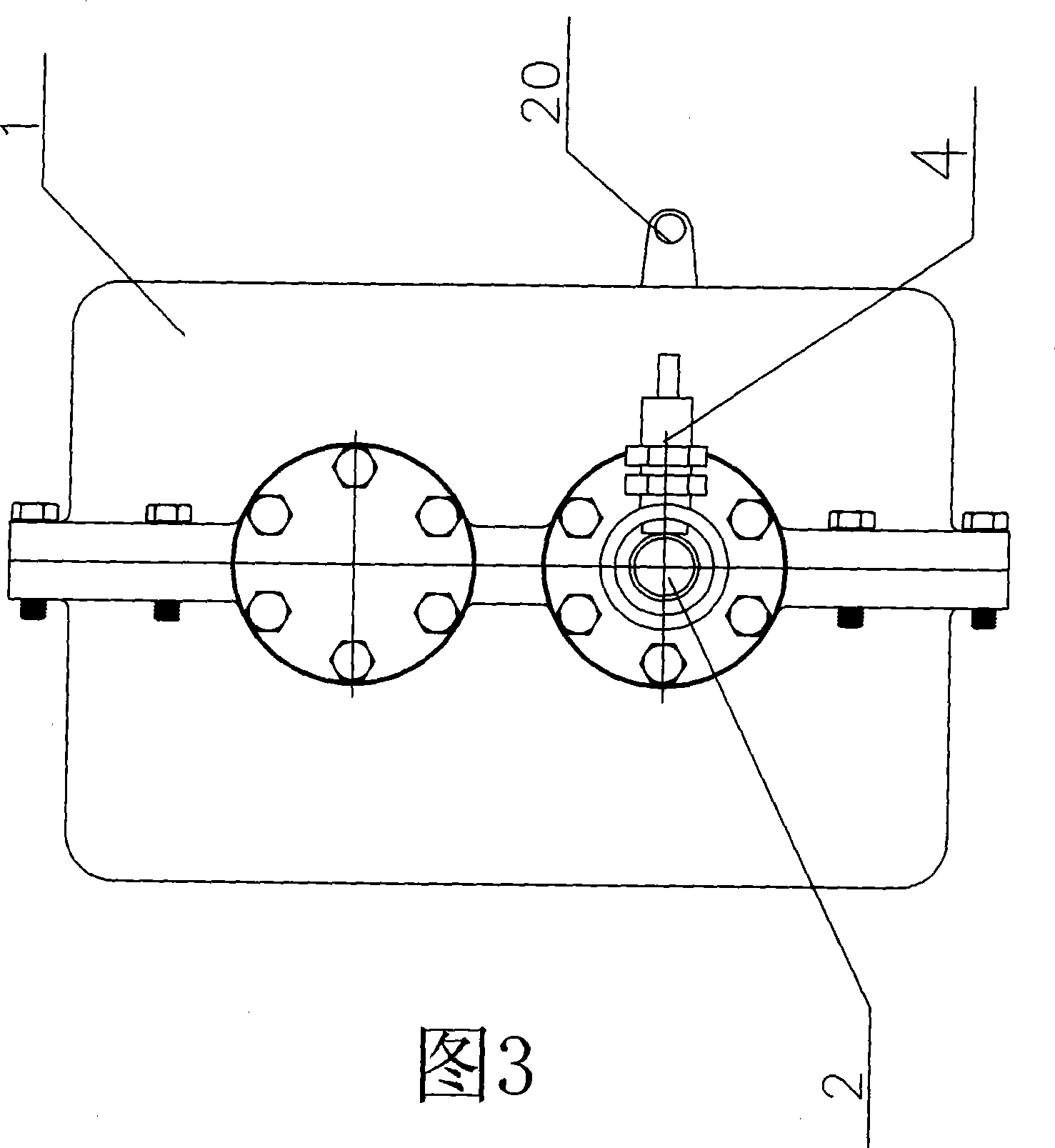

[0021] Embodiment 1: (shown in Fig. 1, Fig. 2, Fig. 3), electric vehicle automatic transmission (two groups of speed change mechanisms) comprises casing 1, power input shaft 2, power output shaft 3, links to each other with power input shaft 2 Input rotational speed sensor 4, input rotational speed sensor 4 is placed outside machine case 1, is provided with two speed change mechanisms in machine case 1-high-speed speed change mechanism 5 and low-speed speed change mechanism 6, wherein high-speed speed change mechanism 5 includes high-speed gear set 7 and high-speed clutch 8. The low-speed transmission mechanism 6 includes a low-speed gear set 9 and a low-speed clutch 10, wherein the high-speed gear set 7 includes a high-speed input gear 11 and a high-speed output gear 12, and the high-speed input gear 11 and the high-speed output gear 12 have the same number of teeth (that is, constant velocity). The high-speed input gear 11 is connected to the driven end 13 of the high-speed ...

Embodiment 2

[0023] Embodiment 2: (as shown in Fig. 4, Fig. 5), electric vehicle automatic transmission (three groups of speed change mechanisms) comprises casing 1, power input shaft 2, power output shaft 3, the input rotational speed sensor that links to each other with power input shaft 2 4. The input rotational speed sensor 4 is placed outside the case 1, and three speed change mechanisms are arranged in the case 1 - a high-speed speed change mechanism 5, a low-speed speed change mechanism 6 and a medium-speed speed change mechanism 22, wherein the high-speed (constant speed) gear of the high-speed speed change mechanism 5 Group 7 includes a high-speed input gear 11 and a high-speed output gear 12, and the high-speed input gear 11 and the high-speed output gear 12 have the same number of teeth, the high-speed input gear 11 is connected with the high-speed clutch passive end 13, and the high-speed clutch active end 14 is connected to the power input through a fixed key. Axis 2 is connect...

Embodiment 3

[0035] Embodiment 3: As shown in FIG. 6 and FIG. 7 , the electric vehicle automatic transmission includes a casing 1 , a power input shaft 2 , a power output shaft 3 , and an input speed sensor 4 connected to the power input shaft 2 . The input speed sensor 4 is placed outside the cabinet 1, and five speed change mechanisms-overspeed speed change mechanism 35, direct speed change mechanism 36, high speed speed change mechanism 5, middle gear speed change mechanism 22 and low speed speed change mechanism 6 are provided in the casing 1.

[0036] The overdrive transmission mechanism 35 is composed of an overdrive input gear 37 , an overdrive output gear 38 , and an overrun clutch 39 . The overrunning input gear 37 is connected with the driven end 40 of the overrunning clutch 39; the overrunning output gear 38 is connected with the power output shaft 3 through a fixed key;

[0037] The direct transmission mechanism 36 is composed of a direct input gear 42 , a direct output gear 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com