Eight-woof single-face plain cloth jacquard weave double-layer towel set and manufacturing method thereof

A manufacturing method and single-sided technology, applied in textiles and papermaking, fabrics, textiles, etc., can solve physical therapy, weight loss, anti-decubitus, diapers, anti-mite, anti-mosquito, can not satisfy consumers, do not interweave, etc. problem, to achieve the effect of soft and plump hand feeling, beautiful appearance and strong three-dimensional sense.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

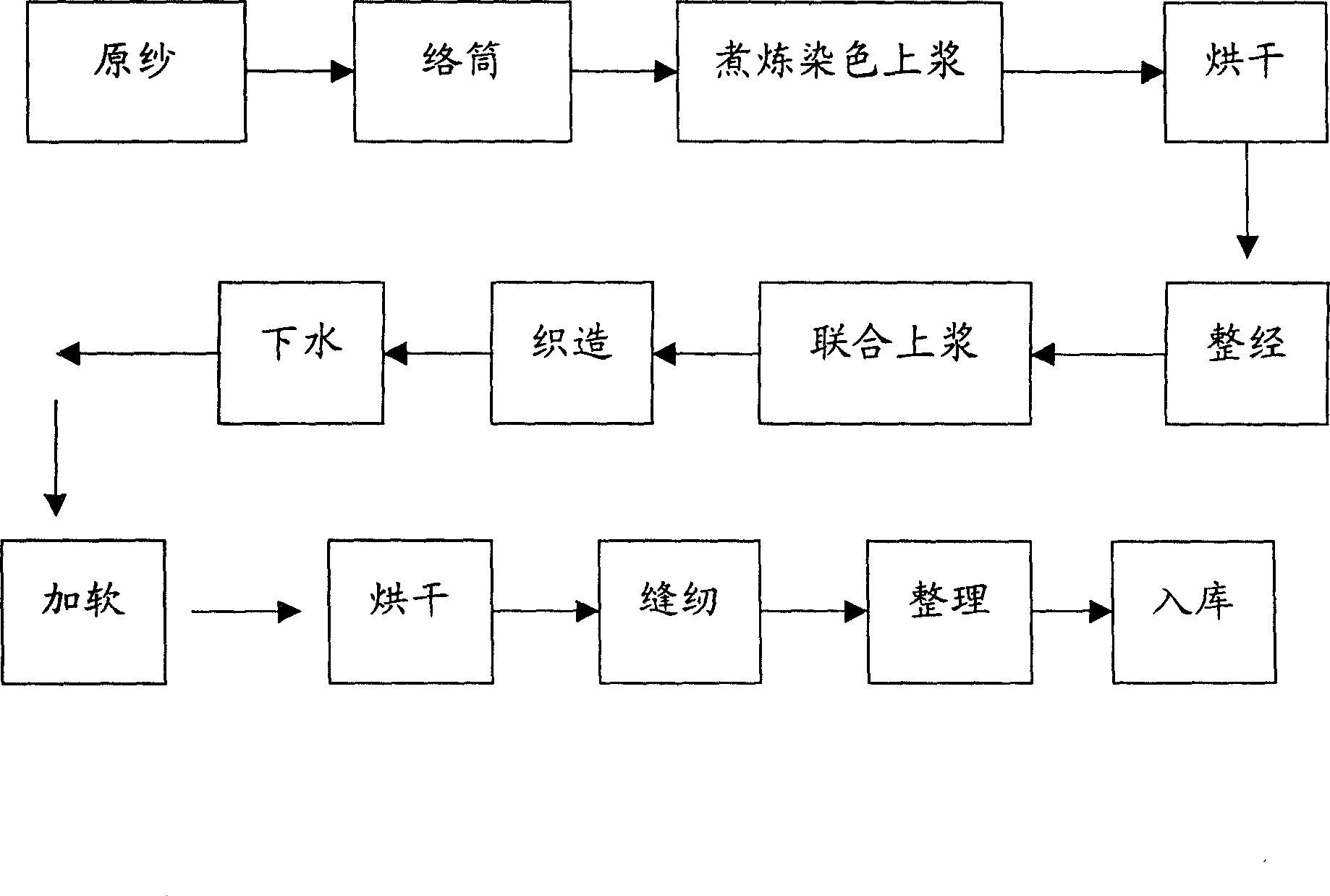

Image

Examples

Embodiment Construction

[0036] In order to make your examiner understand the main technical content and implementation mode of the present invention, the examples are as follows:

[0037] The eight-weft single-sided plain jacquard double-layer towel of the present invention is:

[0038] 100% high-quality combed yarn;

[0039] Wool warp: 18.2*2Tex, compound twist is 36 twists / 10cm;

[0040] Weft yarn: plain cloth layer 18.2*Tex, composite twist 52 twists / 10cm; loop layer 29.2Tex,

[0041] Twist 66 twist / 10cm;

[0042] Ground warp: 18.2*2Tex, composite twist 52 twists / 10cm;

[0043] The warp density of the finished product: 290 pieces / 10cm, the reed number is No. 64 reed;

[0044] The weft density of the finished product: 448 threads / 10cm, of which the plain cloth layer is 112 threads / 10cm, and the loop layer

[0045] 336 roots / cm; ground hair warp root ratio 3:1; loop length: 0.81cm; hair fold: 4.5cm;

[0046] Weaving parameters:

[0047] Model 200cm G6200 STRAUBILL 5680 jacquard machine;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com