Adjustable sliding table top

A table top and sliding technology, applied in the field of conveyors, can solve the problems of inflexible driving, heavy structure, easy to get stuck, etc., and achieve the effect of flexible running direction, accurate transportation, and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

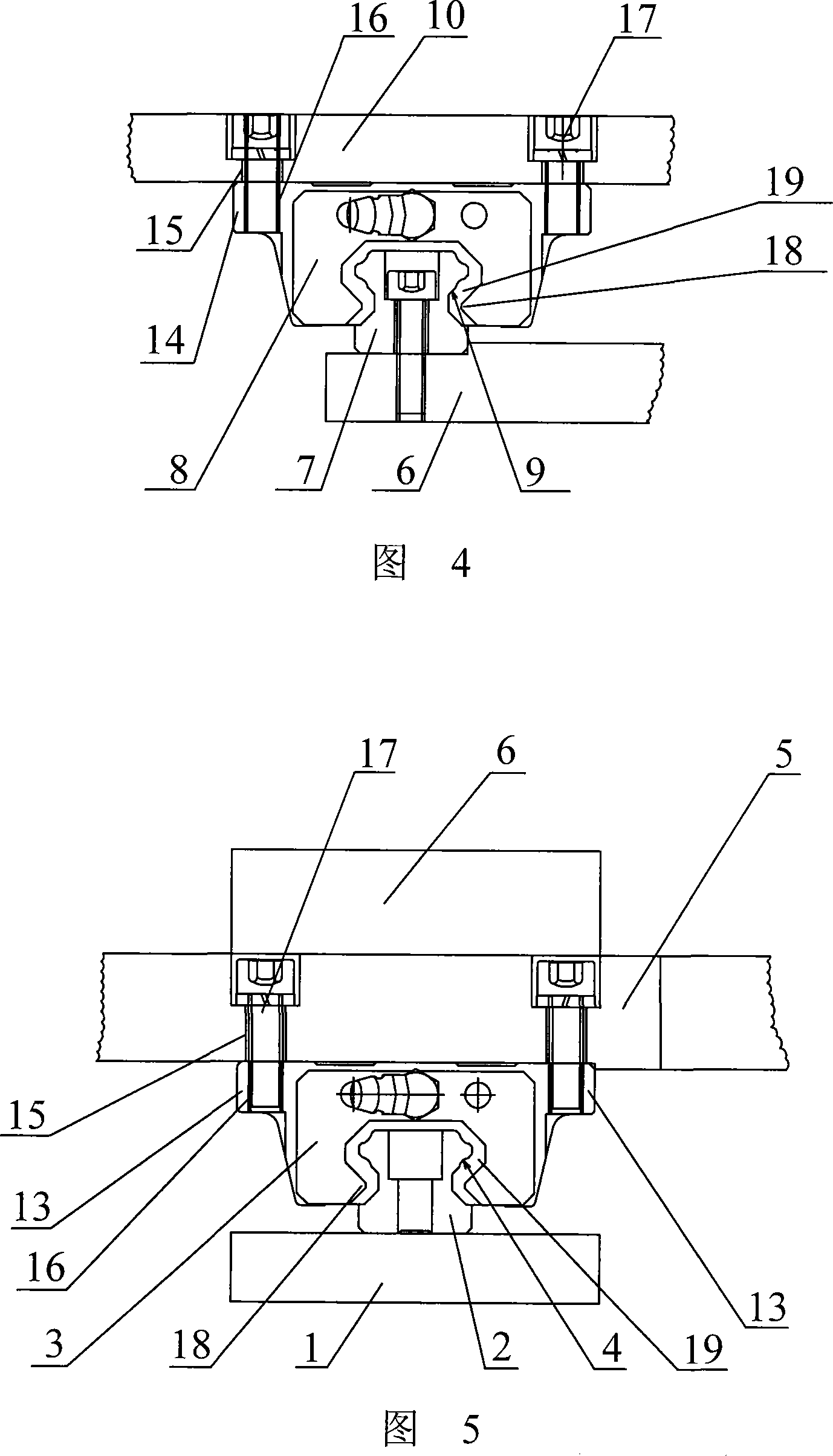

[0015] As shown in the figure: the adjustable sliding platform of the present invention is fixed on the base 1 with a number of strip-shaped horizontal protrusions 2 arranged in parallel, and a horizontal sliding seat 3 is buckled on the outer side of the upper part of the transverse protrusions 2. The lower part of the slide seat 3 is provided with a transverse groove body 4, and the top surface of the transverse groove body 4 is pressed against the top surface of the transverse protrusion 2, and the transverse protrusion 2 and the transverse groove body 4 are slidably matched, so that the transverse protrusion 2 A part is embedded in the transverse groove body 4, and two or more longitudinal guide rails 5 are erected on the upper surface of the transverse slide seat 3, and a mounting plate 6 is erected on the upper surface of the longitudinal guide rail 5, and several strips are fixed on the mounting plate 6. Longitudinal bulges 7 arranged parallel to each other, a longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com