Automatic board drilling machine

A drilling machine and plate technology, which is applied in the direction of veneer presses, plywood presses, stone processing tools, etc., can solve the problems of poor drilling hole shape, thin plate drilling is easy to break through and break, and achieve the goal of overcoming The effects of piercing and breaking, reducing structural strength requirements, and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

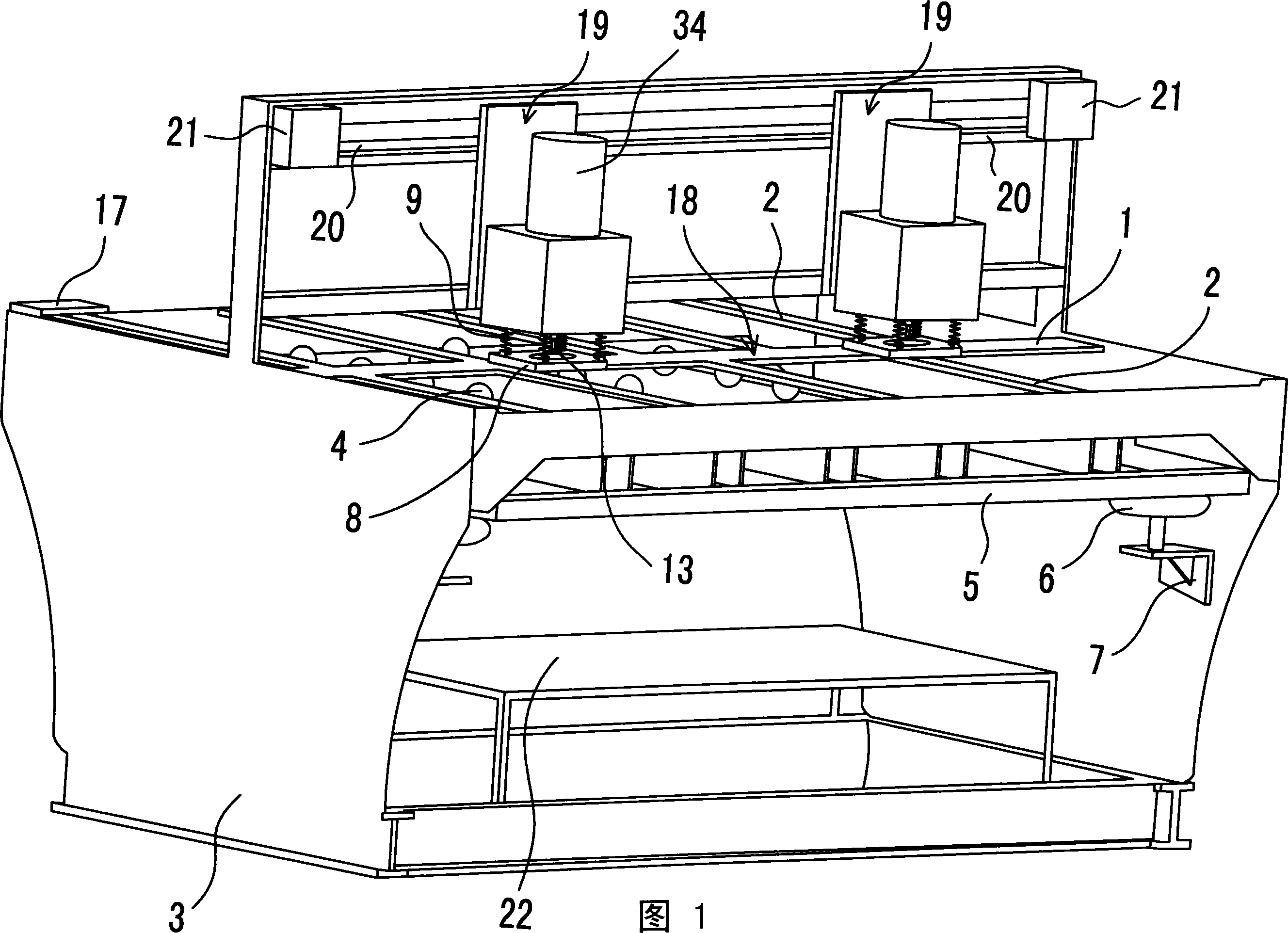

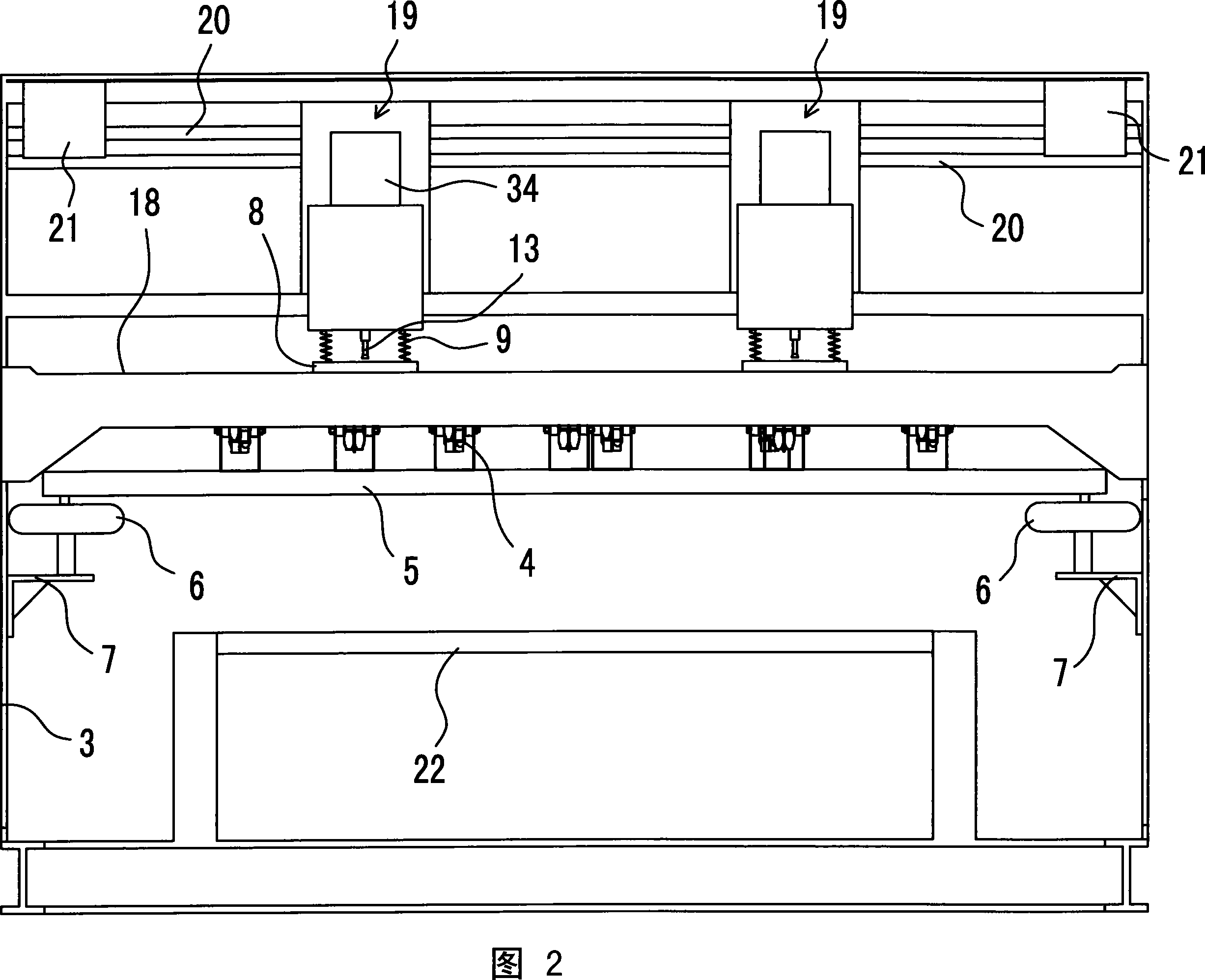

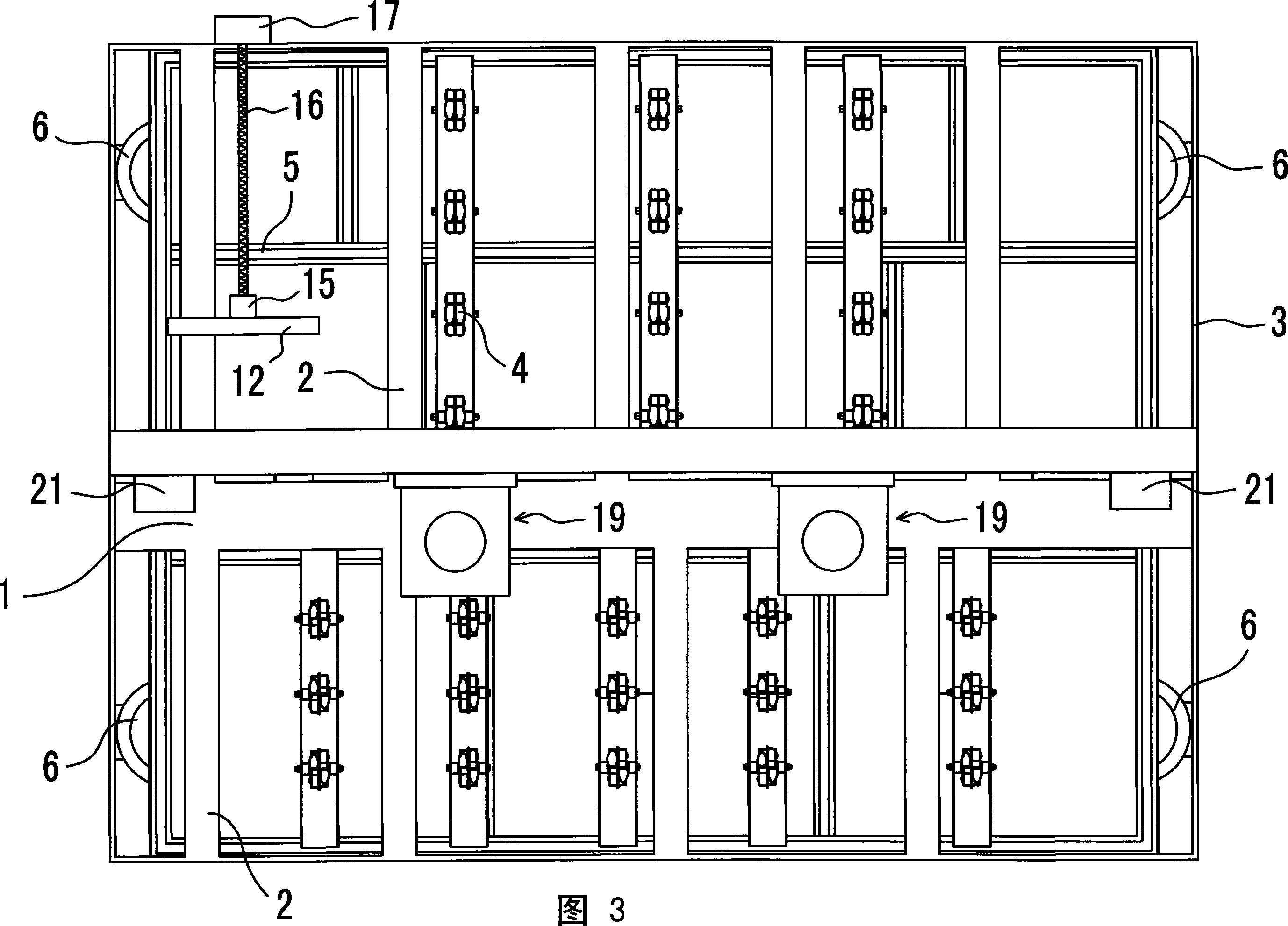

[0049] As shown in Figure 1, Figure 2, Figure 3 and Figure 4, an automatic plate drilling machine with good drilling quality, strong drawing force and high processing efficiency consists of a frame 3, a table positioning mechanism, a drilling device and The electric control cabinet consists of several parts (because the electric control part is prior art, it will not be described in detail here).

[0050] The table positioning mechanism is composed of a plate horizontal support mechanism and a support positioning mechanism in the X direction and Y direction in the horizontal plane. The plank horizontal support mechanism is composed of the dislocation combination of the fixed support table top 18 and the lifting roller support table top. The fixed support table 18 is provided with a main support plate 1 arranged along the X direction (horizontal and transverse direction of the front of the complete machine), and the main support plate 1 is located directly below the drill bit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com