Longitudinal whole-process automatic feeding and positioning device and method

A positioning device and full-automatic technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of low precision and position precision, low degree of automation, high labor intensity, etc., to achieve improved production efficiency, convenient operation, The smooth effect of the conveying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

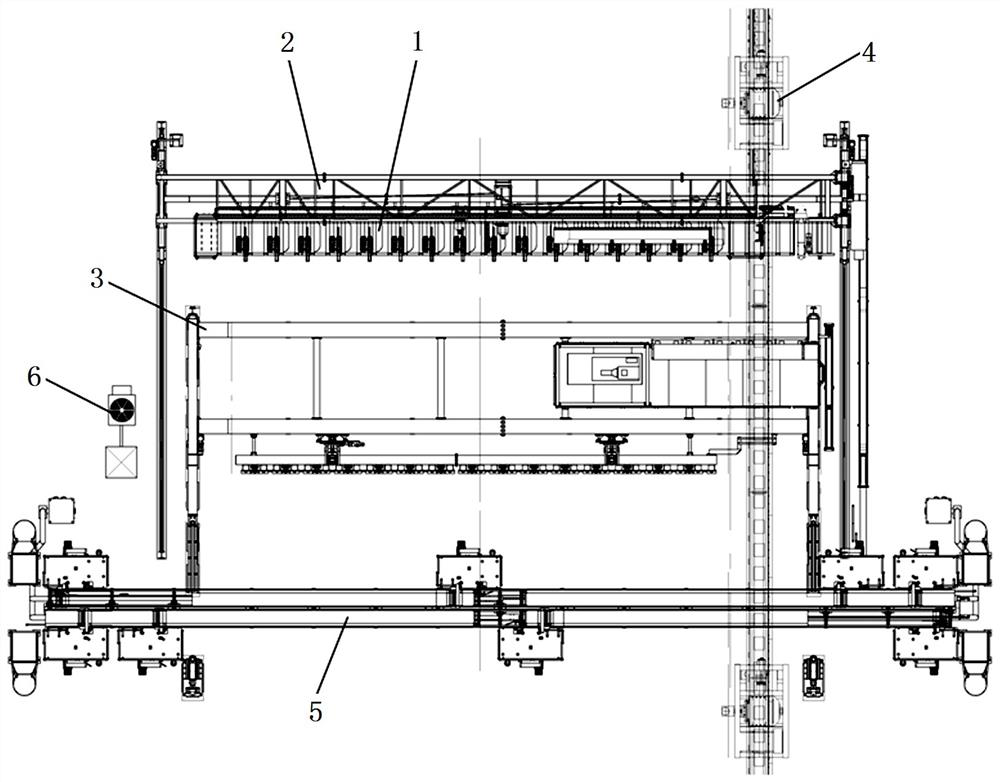

[0082] see figure 1 , a full-range automatic feeding and positioning device for longitudinals, comprising a longitudinals feeding device 1, an electromagnetic retrieving gantry 2, a longitudinals positioning trolley 3, and a segment conveying device 4 arranged in sequence along the direction of the production line.

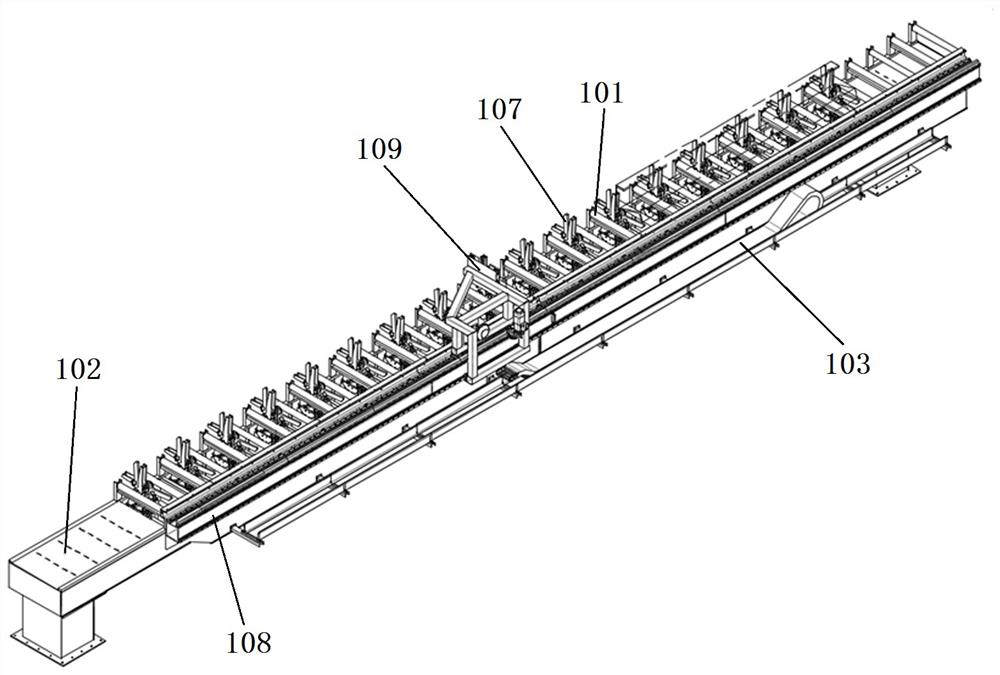

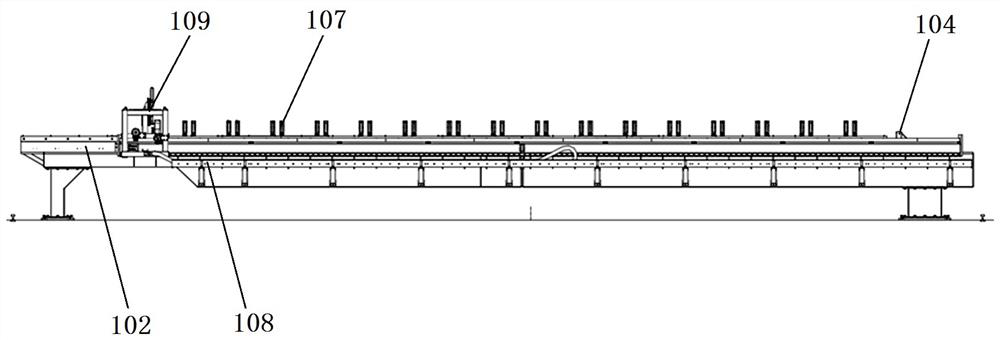

[0083] see Figure 2 to Figure 4 , The longitudinal bone feeding device 1 includes a feeding roller table, a vertical positioning device, and a longitudinal positioning device.

[0084] The feeding roller table is used to convey the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com