Rotating continuous mixing machine

A mixer and rotary type technology, applied in the direction of mixers with rotating containers, mixers, dissolving, etc., can solve the problems of high energy consumption, unsuitability for continuous industrialized large-scale production, and large material fragmentation, so as to achieve low energy consumption, Mixed effect with mild exercise and low residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

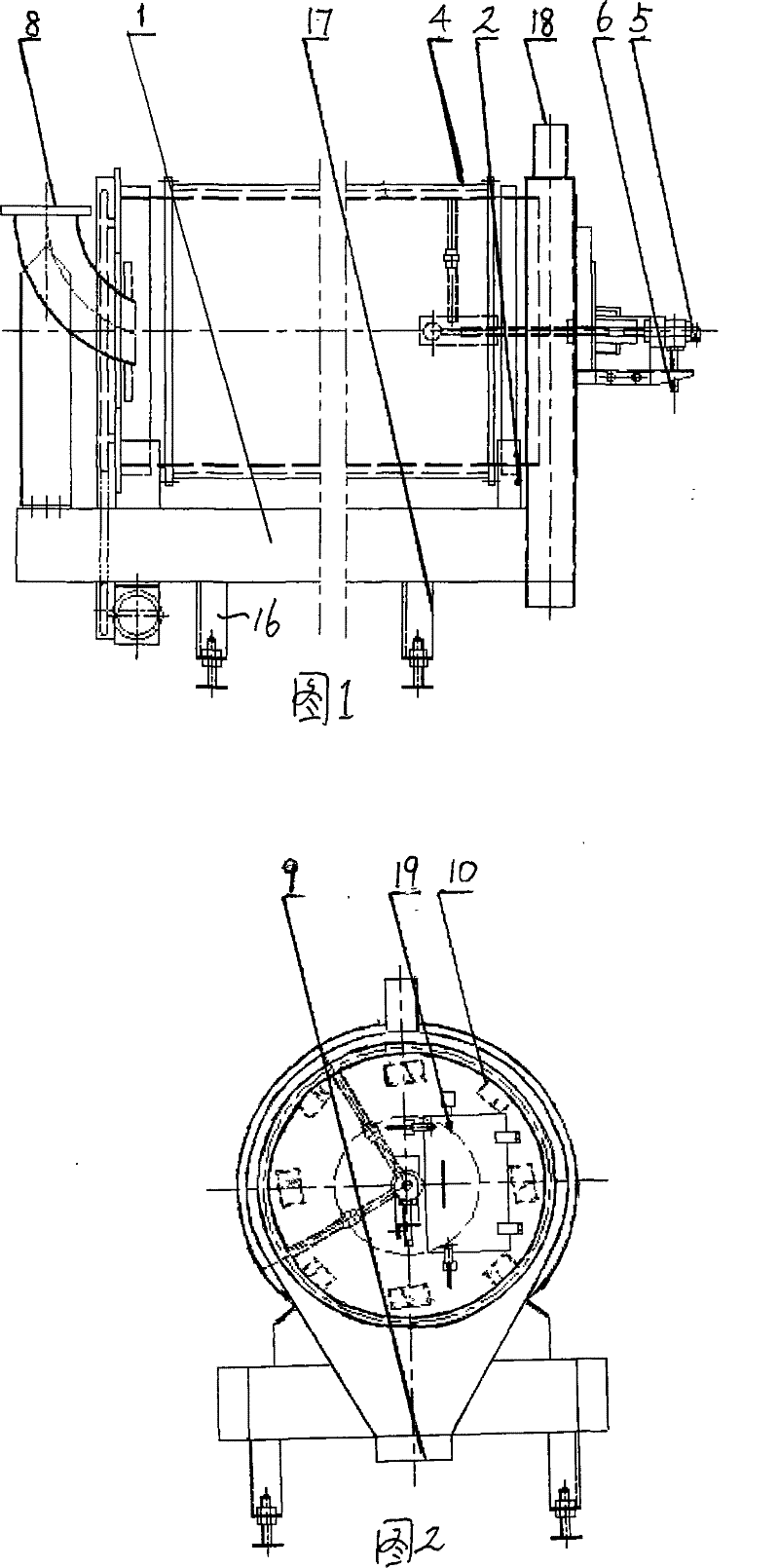

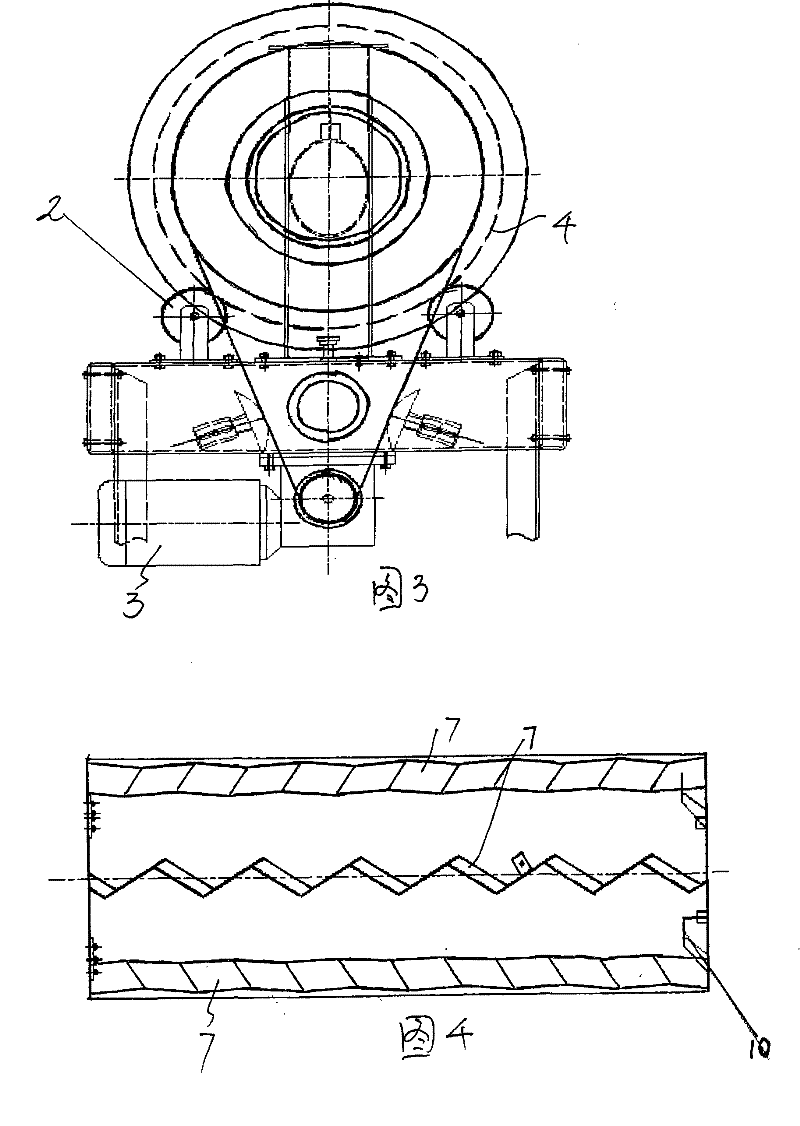

[0021] A rotary continuous mixer, comprising a frame 1, a roller 2 mounted on the frame 1, a roller 4 driven by a driving device 3 is arranged on the roller 2, the barrel of the roller 4 is in the form of a jacket, and the jacket and the steam inlet and outlet 5 and 6 are interlinked, and the inner wall of the cylinder is fixed with the mixing screw 7 arranged longitudinally. The mixing screw 7 has more than 2 rows (generally 2 to 6 rows) and is evenly distributed along the circumference of the cylinder. The drum 4 and the material feed, The outlets 8 and 9 communicate with each other. At the material outlet end of the cylinder body, a discharge device 10 fixedly connected with the cylinder body is arranged, and an exhaust port 18 is arranged above the material outlet part.

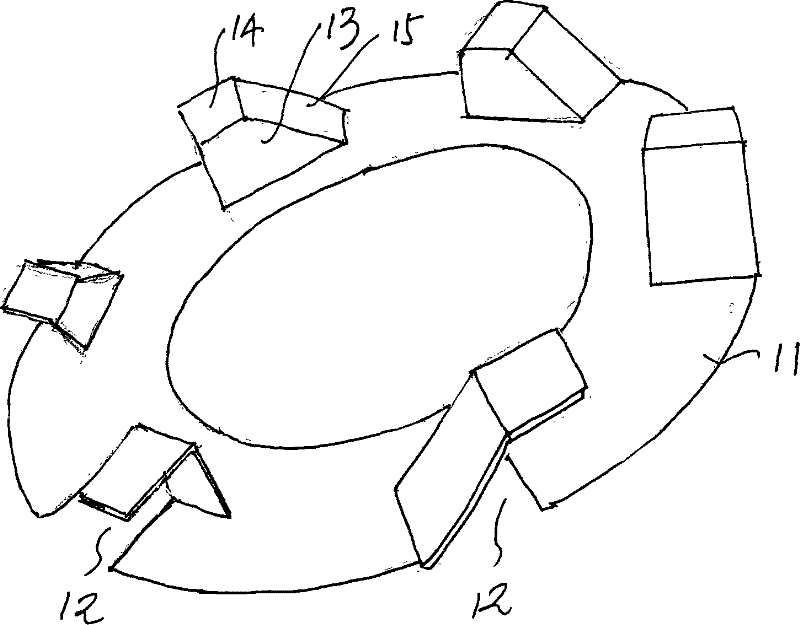

[0022] The discharge device 10 includes an annular body 11 fixedly connected to the inner wall of the cylinder. A plurality of material outlets 12 arranged along the circumference are arranged on the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com