Connector pin for printed circuit board

A technology for printed circuit boards and connectors, applied in the field of connectors for printed circuit boards, can solve the problems of copper foil pattern falling off or peeling, reducing welding effect, and excessive application, so as to reduce poor contact or poor action, and improve bonding. The effect of force, reinforcement welding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. In the present invention, the content closely related to the gist of the present invention will be described emphatically, and the description of some known specific structures will be omitted.

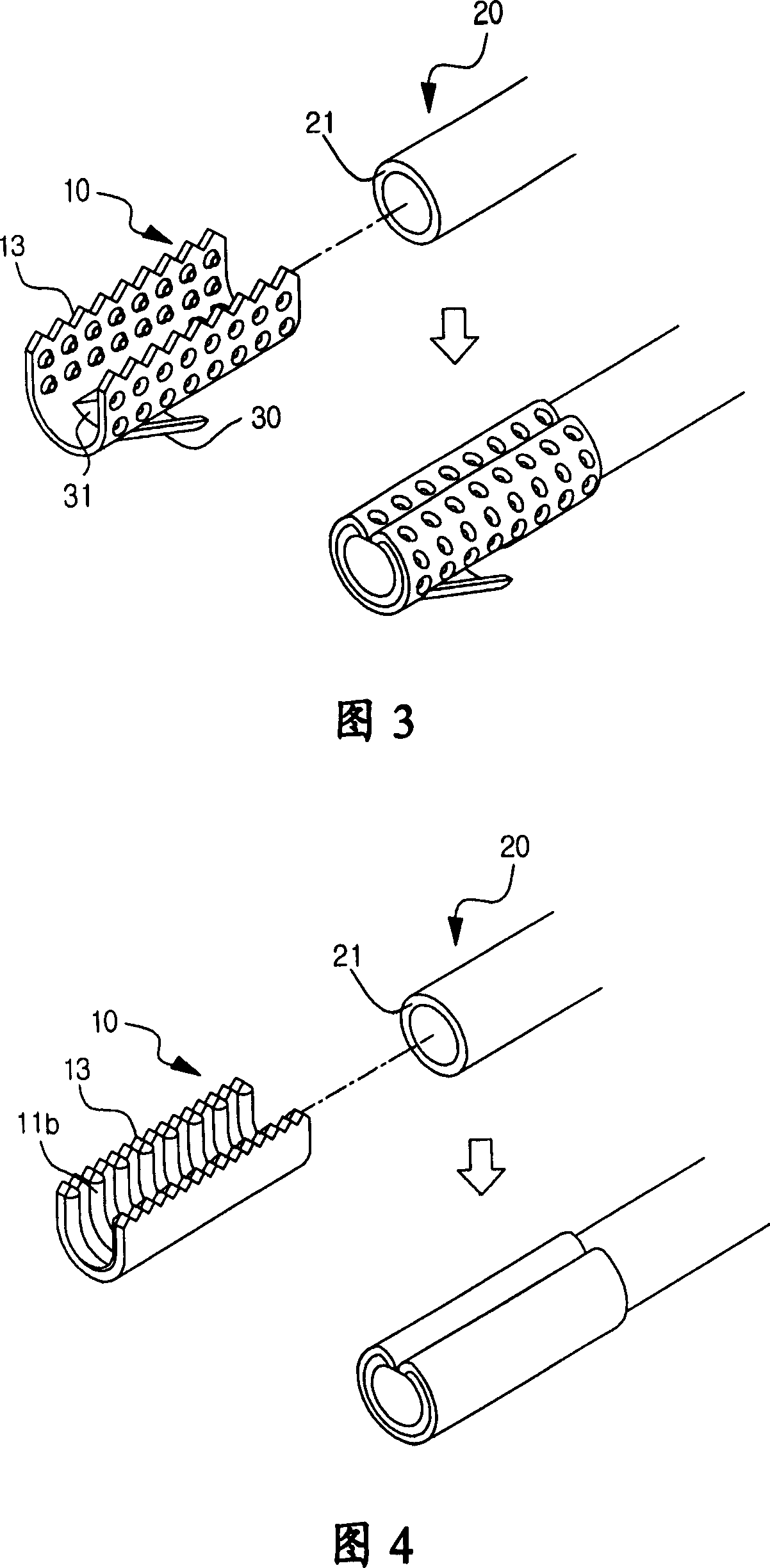

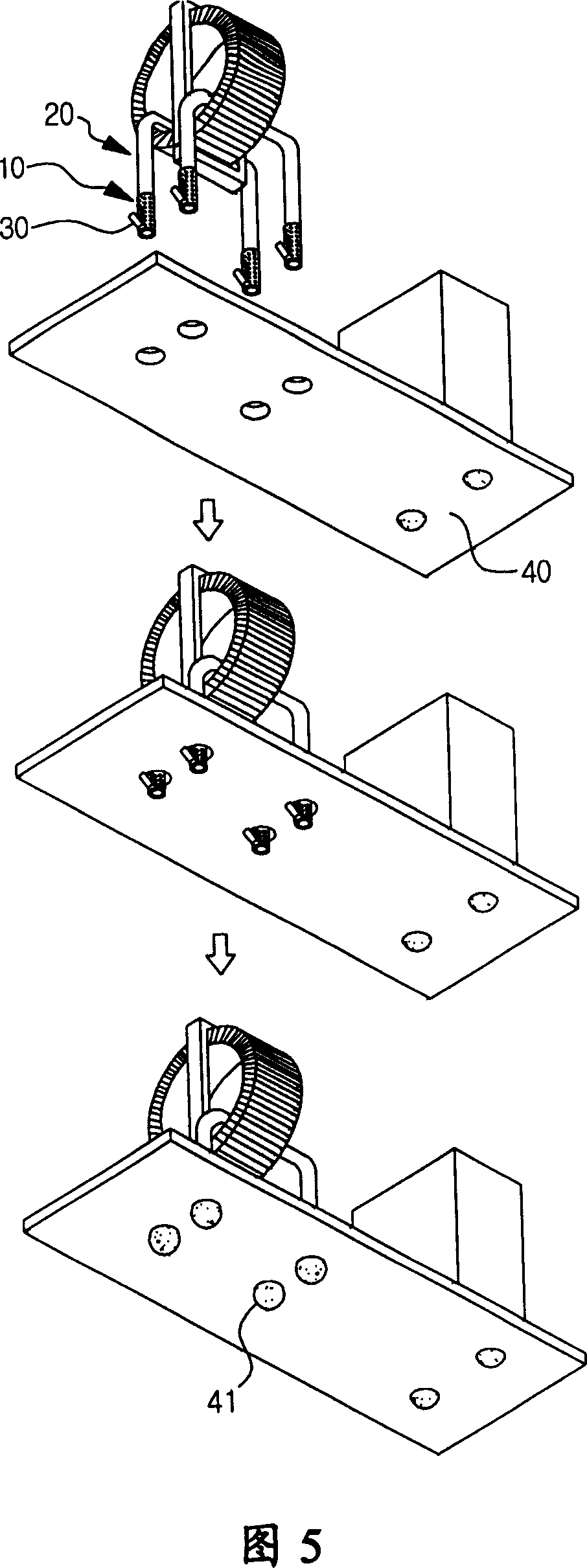

[0020] As shown in Figure 1, according to a connector for printed circuit boards according to an embodiment of the present invention, a plurality of cylindrical protrusions 11a are formed on the inner surface of the upper open semicircular connector 10, and through holes are processed at the tail ends of the protrusions 11a 12. Place the coil 20 on the inner surface of the connector 10, crimp both sides of the connector 10, and make the protrusion 11a cut through the covering layer 21 of the coil 20.

[0021] The shape of the connector 10 may be changed according to the shape of the coil or parts so that the target coil or various parts are located on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com