Umbrella-shaped structure for combined insulator of high altitude ice-covering area

A composite insulator, high-altitude technology, applied in the direction of insulators, suspension/strain insulators, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

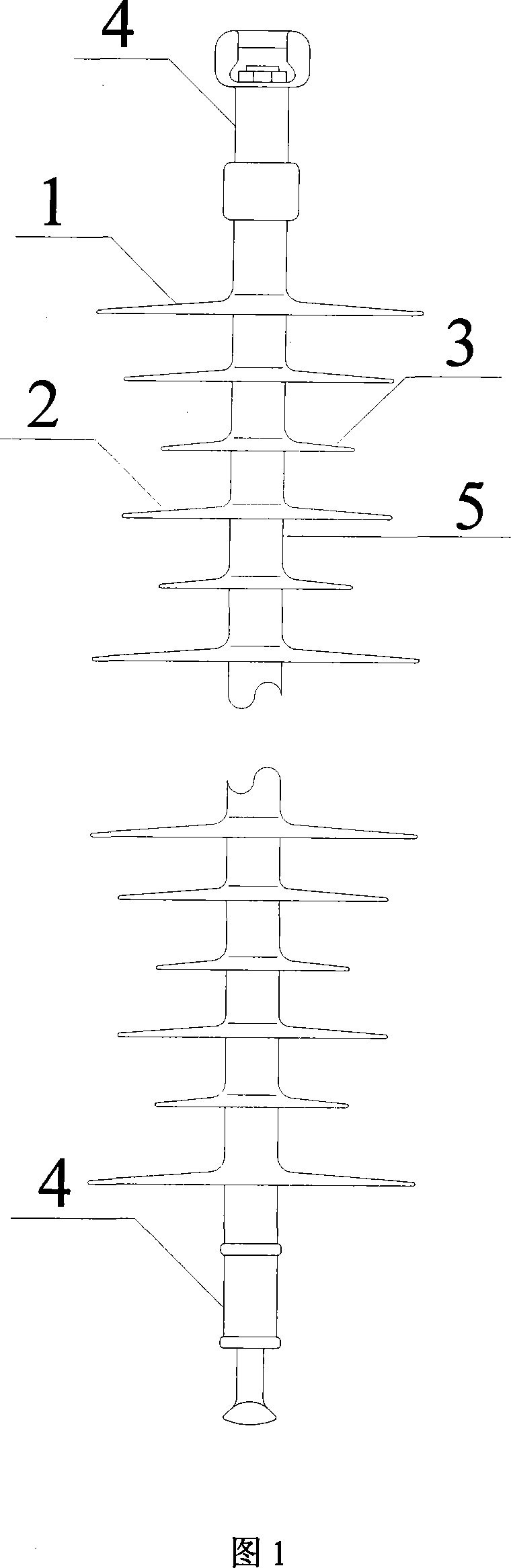

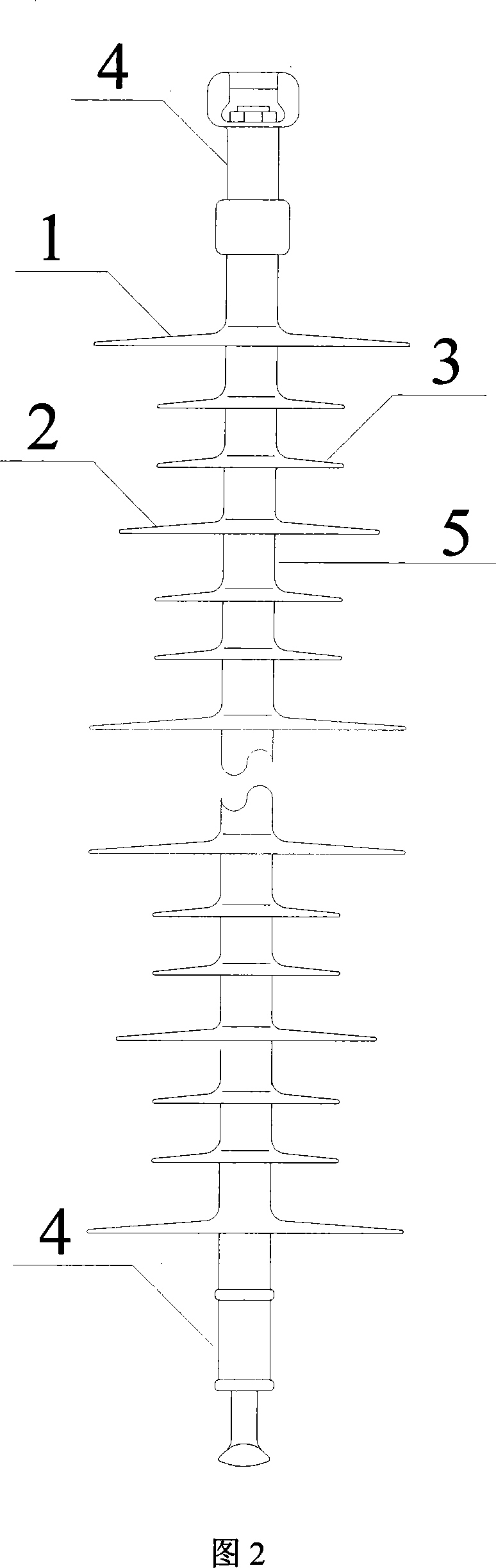

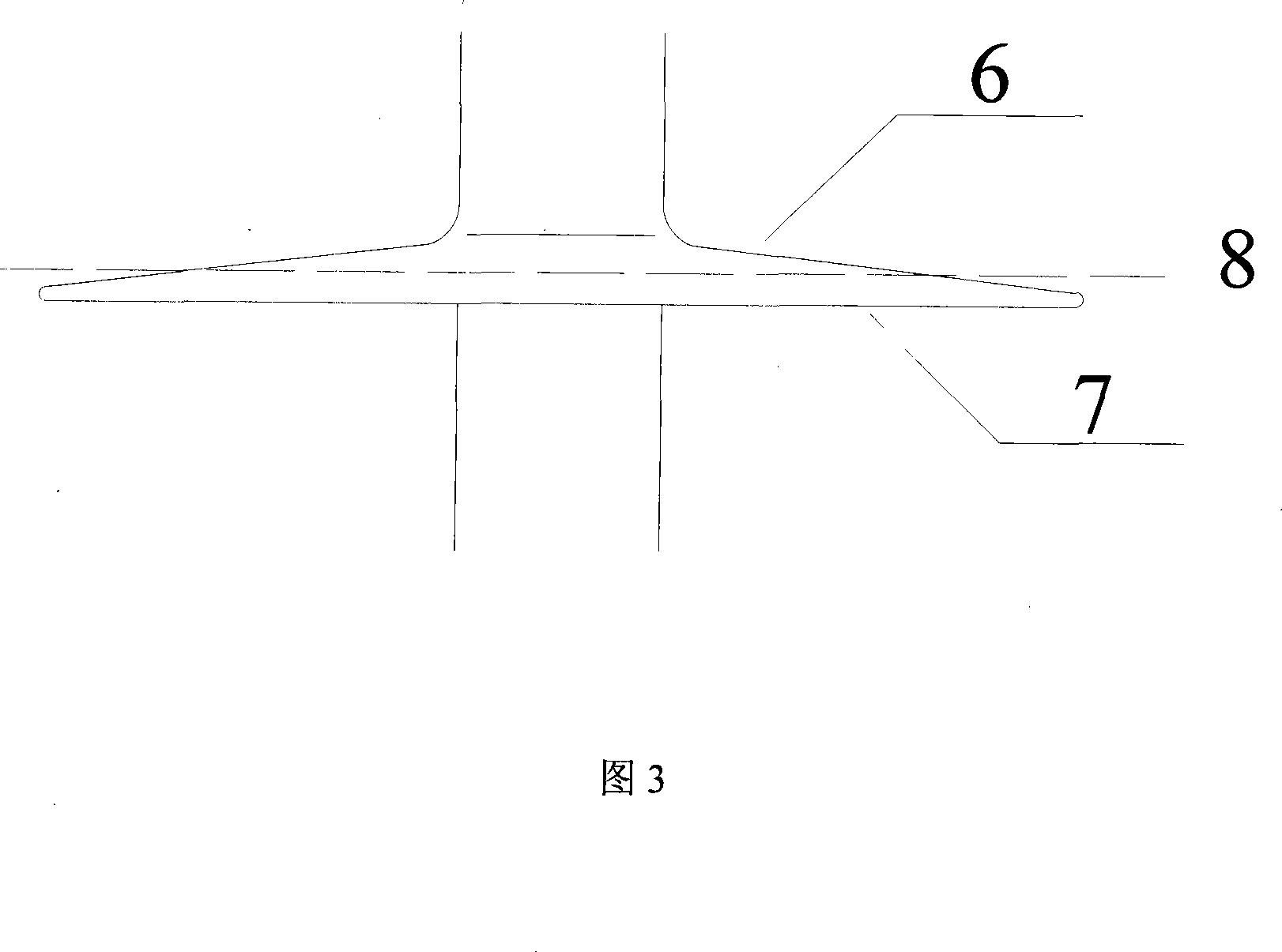

[0013] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings:

[0014] The umbrella structure of the composite insulator used in the high-altitude ice-coated area provided by the present invention uses the finite element method to simulate the surface electric field of the composite insulator under high-altitude and ice-coated conditions. The research results show that the structure of the composite insulator has a significant effect on the electric field distribution. Obviously, the larger the diameter of the umbrella skirt of the composite insulator, the smaller the electric field strength at the tip of the ice edge on the surface of the ice-coated composite insulator. When the diameter of the umbrella skirt is greater than 210mm, the electric field intensity at the tip of the ice edge on the surface of the ice-coated composite insulator tends to be saturated; The small surface inclination of the insulator she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com