Dust collection device for an handheld electrical tool

A technology for electric tools and dust collection, which is applied in the direction of portable motorized devices, manufacturing tools, striking tools, etc. It can solve the problems of reduced suction power, clogged dust filter, severe damage, etc., and achieve the effect of reduced suction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

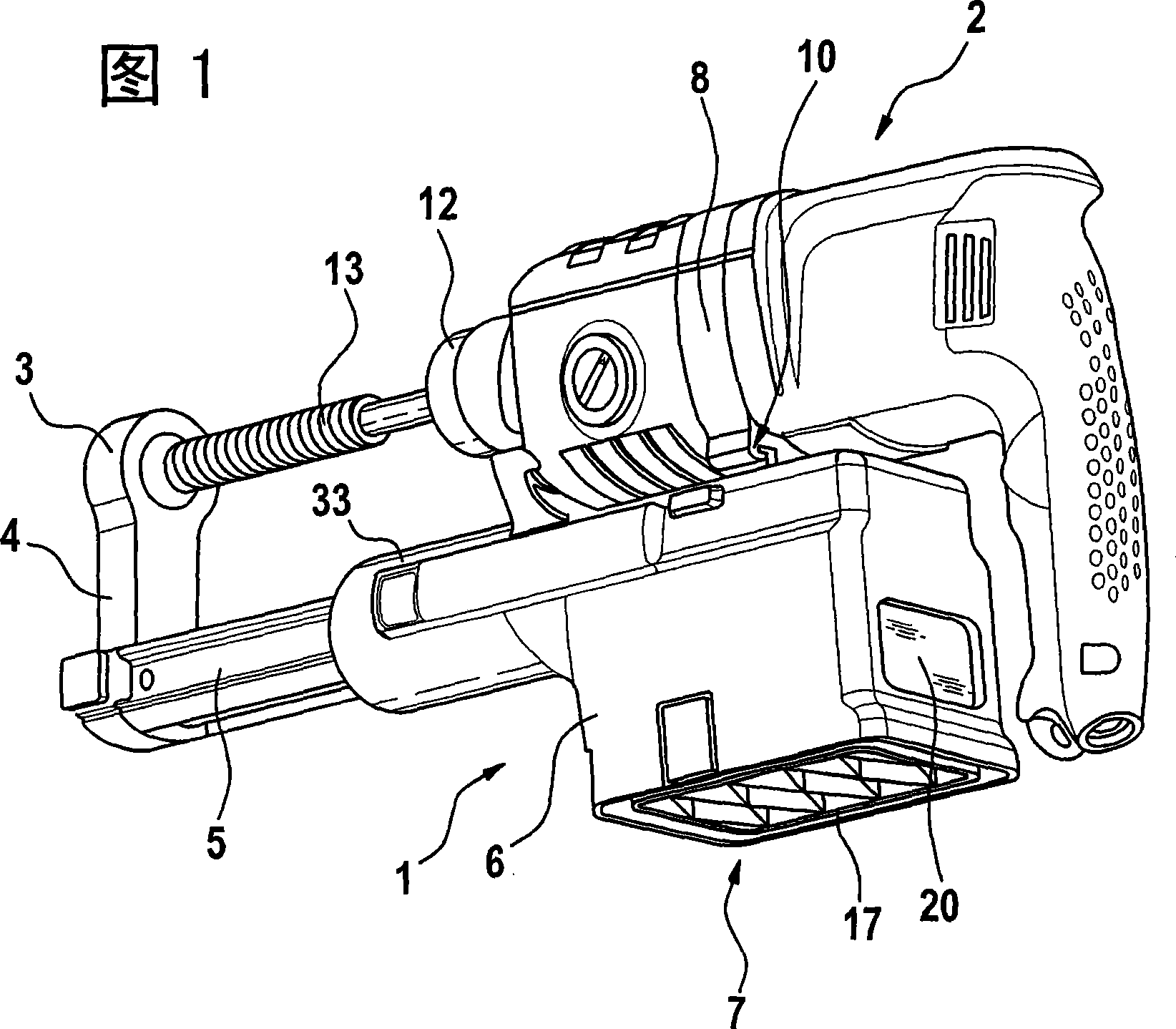

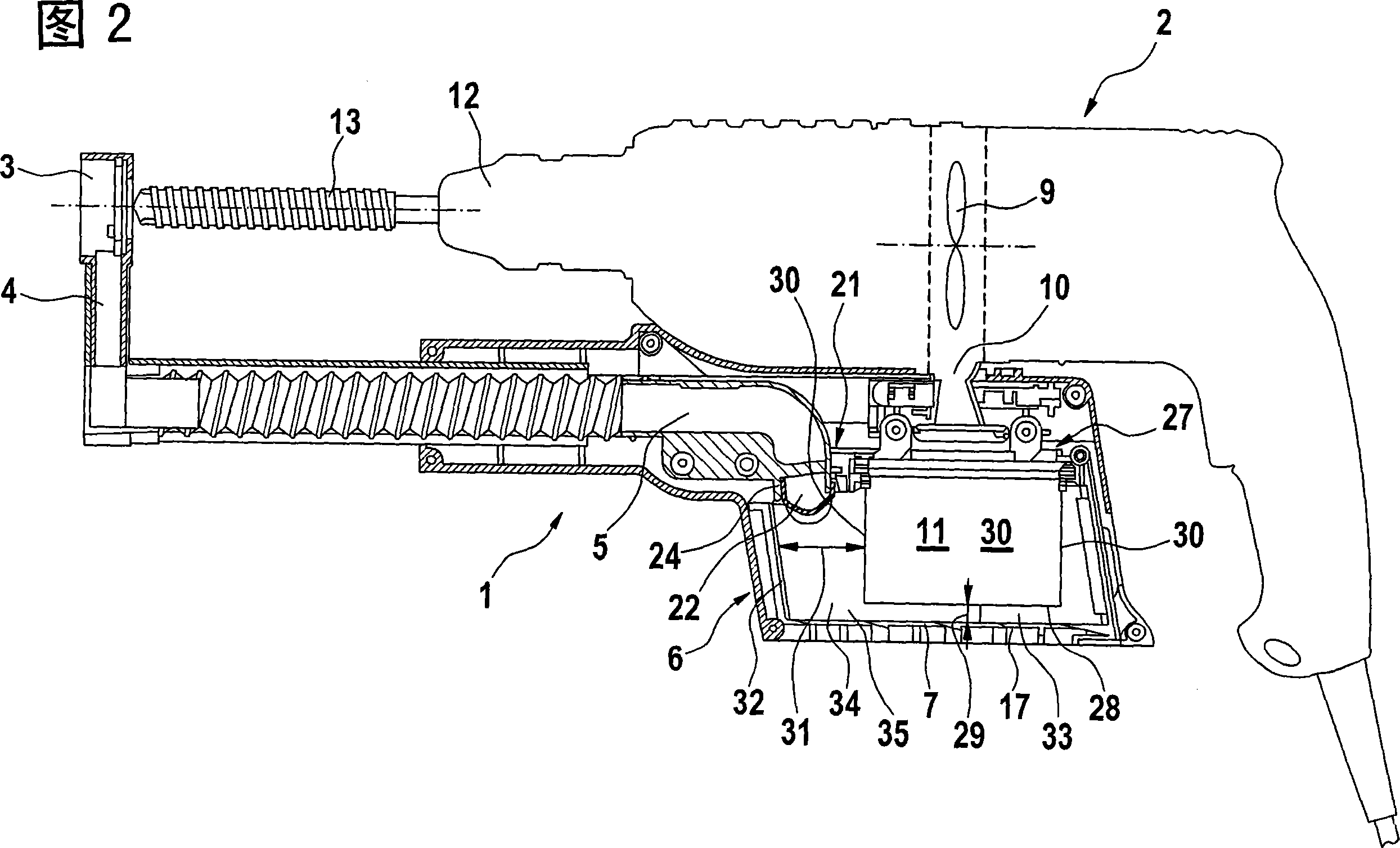

[0023] FIG. 1 shows a dust collection device 1 which is detachably and lockably connected to a hand-held power tool 2 . The hand-held power tool is a percussion drill. Instead of a hammer drill, conventional drills or hammer drills can also be used.

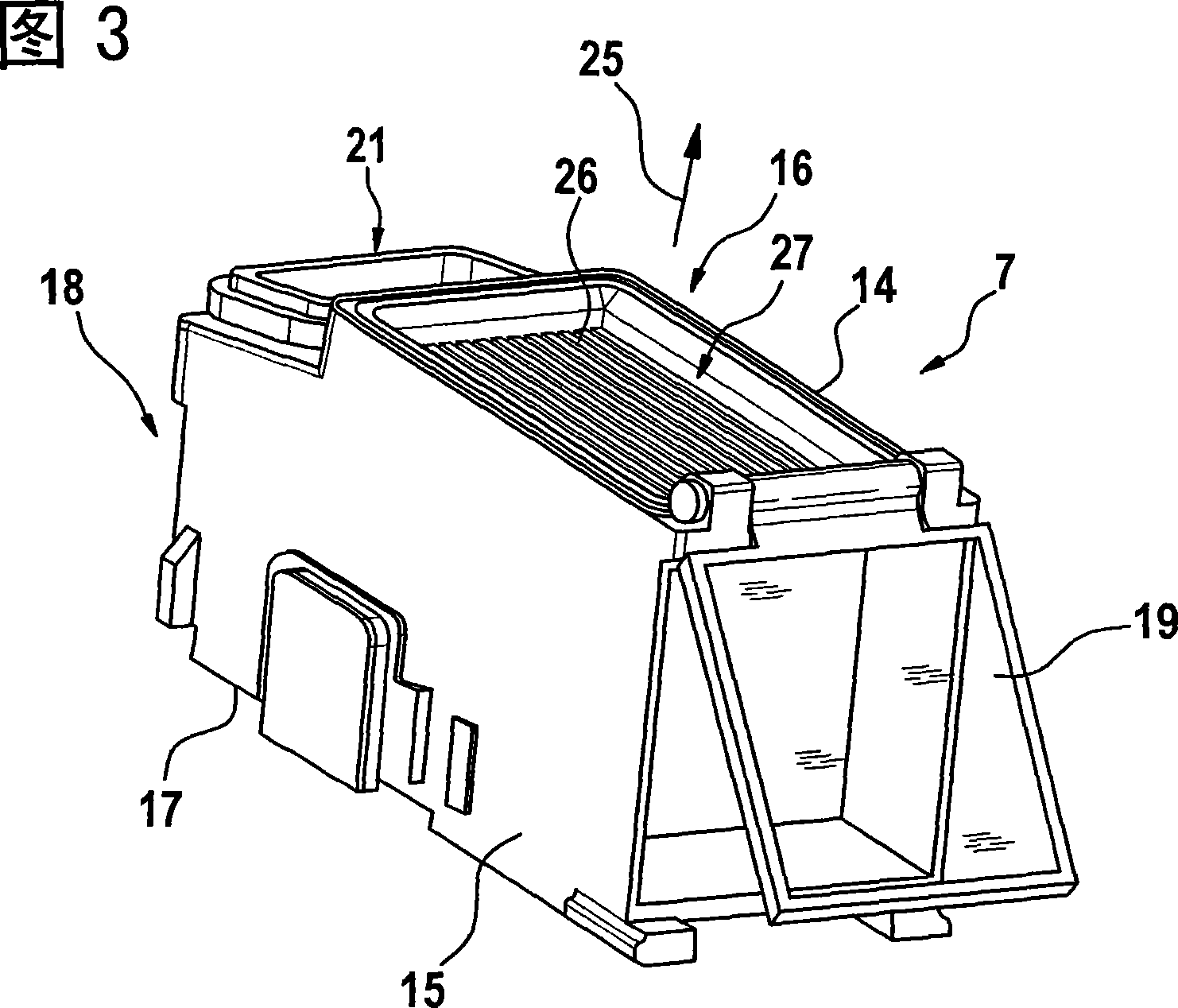

[0024] The dust collecting device 1 has a dust suction opening 3 which is connected via a suction channel 4 and a telescopic suction channel 5 to a housing 6 which can be removed by means of a suitable detachable The locking mechanism is fixed on the hand-held electric power tool 2 . In the housing 6 there is a dust container 7 which can be removed downwards. The hand-held power tool 2 has a suction module 8 , whose suction fan impeller 9 ( FIG. 2 ) is driven by the drive motor of the hand-held power tool 2 . The suction fan wheel 9 is connected via a chimney-shaped suction channel 10 to the dust container 7 via a replaceable dust filter 11 ( FIG. 2 ).

[0025] As can be seen from FIG. 1 , a drill bit 13 is clamped into the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com