Construction technique for plastering vitrified brick at positive angle

A construction process and vitrified tile technology, applied in covering/lining, construction, building structure, etc., can solve the problems of easy to cause sharp corners to hurt people, sharp corners to be easily damaged, sharp corners to hurt people, etc., and achieve a good look and feel. Hand feel, avoid sharp corners from hurting people, smooth and rounded outer corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

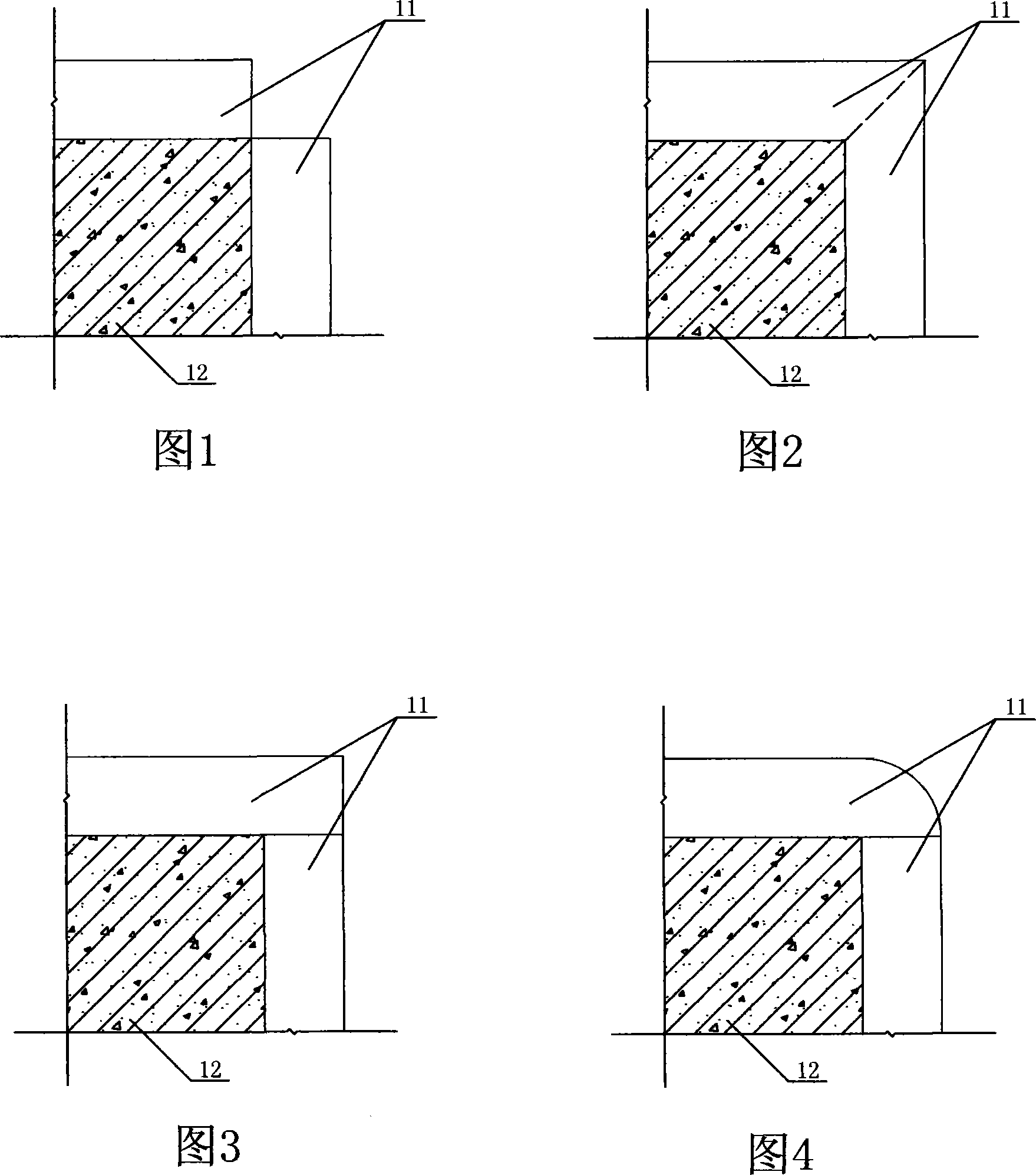

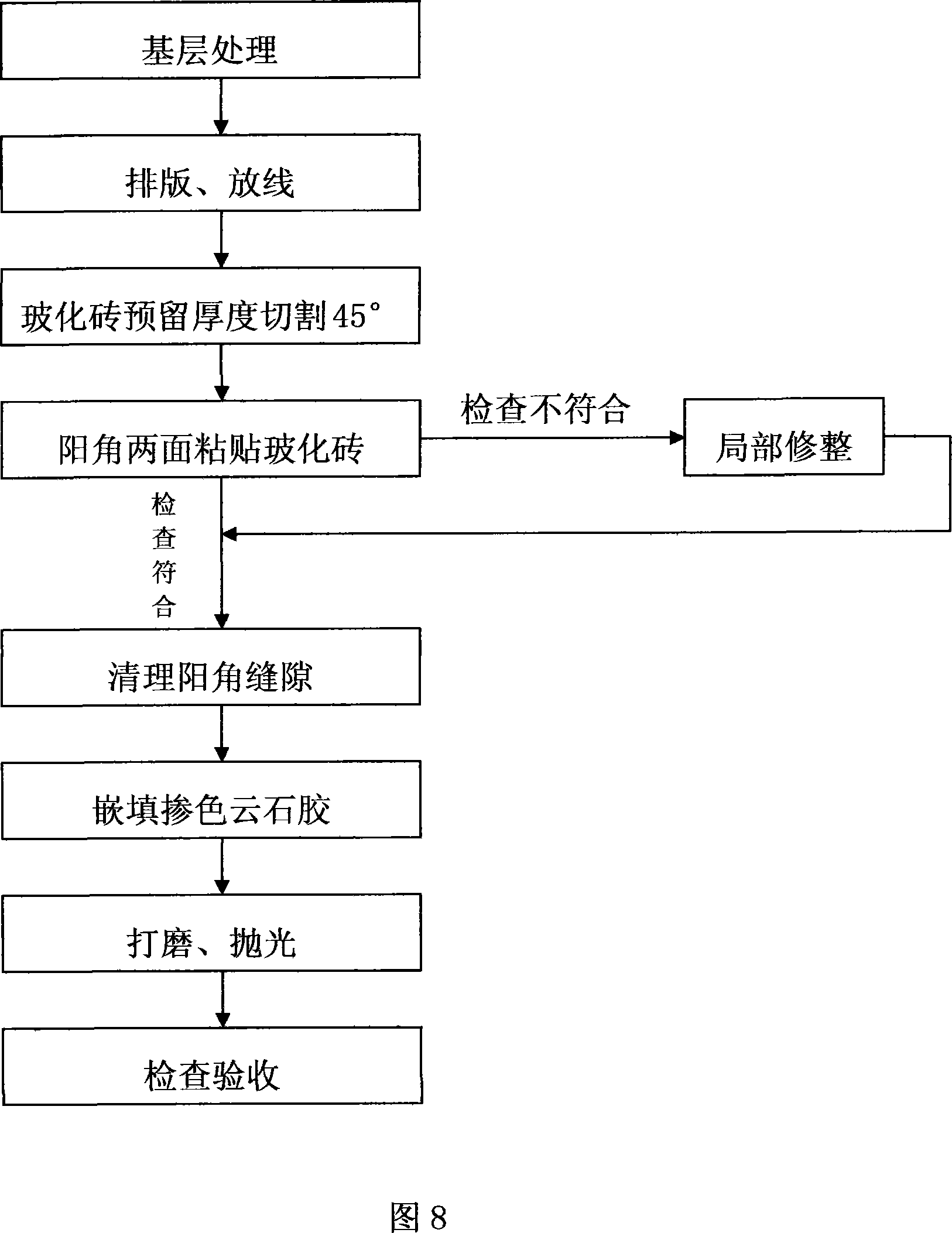

[0021] Clean the base layer, check the flatness and verticality of the surface of the structure before typesetting and laying out lines; typesetting must ensure that both sides of the positive corner are full bricks. According to the engineering decoration design, computer typesetting is carried out one by one. Each part is arranged according to the length from the male corner to the female corner, and the whole brick is arranged from the male corner to the female corner. Two piece approach. On the facade, the whole brick is arranged from bottom to top.

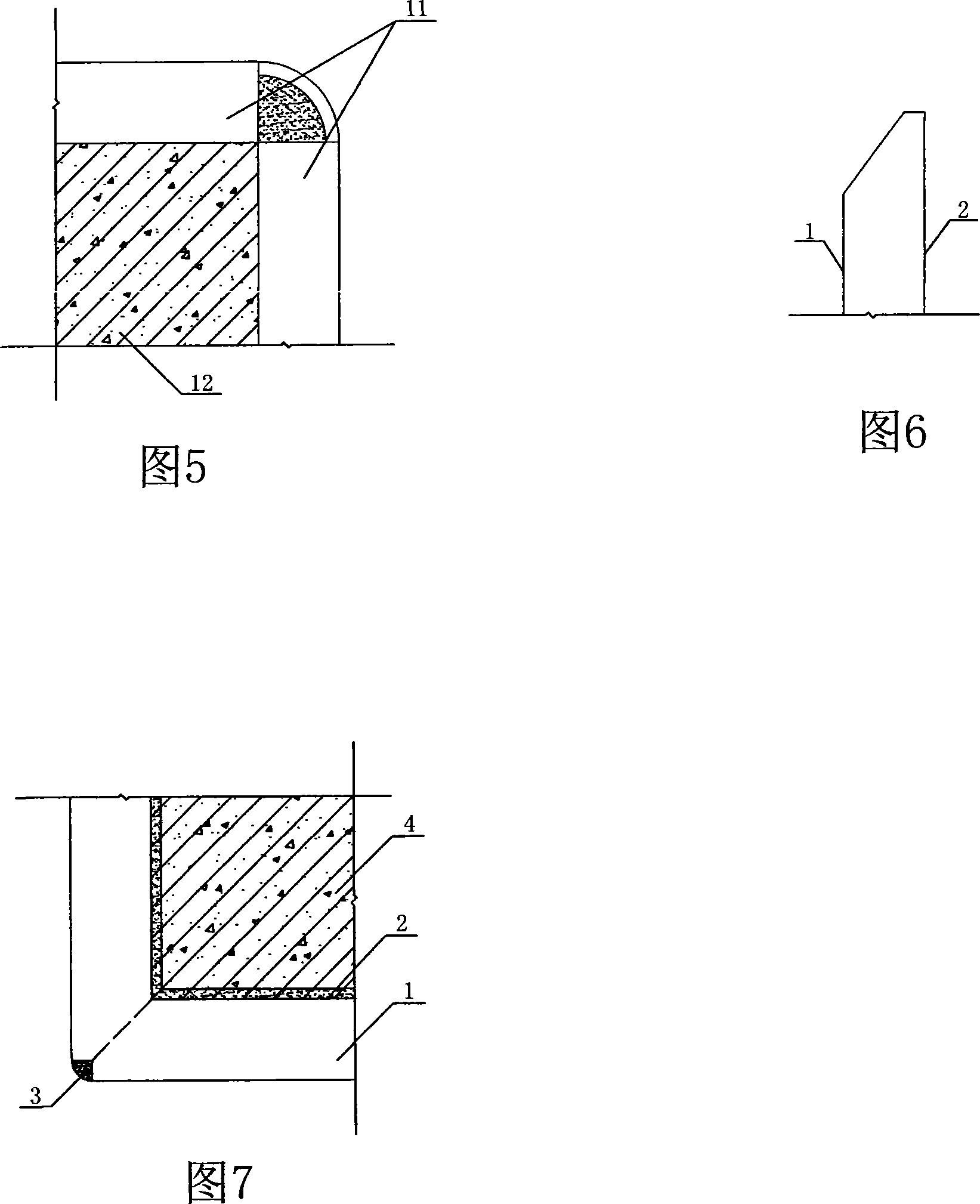

[0022] The cutting process is between the smooth surface 1 of the vitrified brick and the rough surface 2 of the vitrified brick, and a thickness of 3 mm is reserved at the smooth surface 1 of the vitrified brick, and then cut at an angle of 45° with the rough surface of the vitrified brick.

[0023] The vitrified bricks do not need to be immersed in water before the construction, and the cement mortar prepared at a ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com